Basic Info.

Model NO.

Letong27

Certification

CE, RoHS, GS, ISO9001

Type

Sand Casting

MOQ

1 Set

Quality

Good

User

Foundry

Transport Package

Wood and Steel

Specification

0.2kg-11 tons

Trademark

letong

Origin

China

Production Capacity

100sets Per Year

Product Description

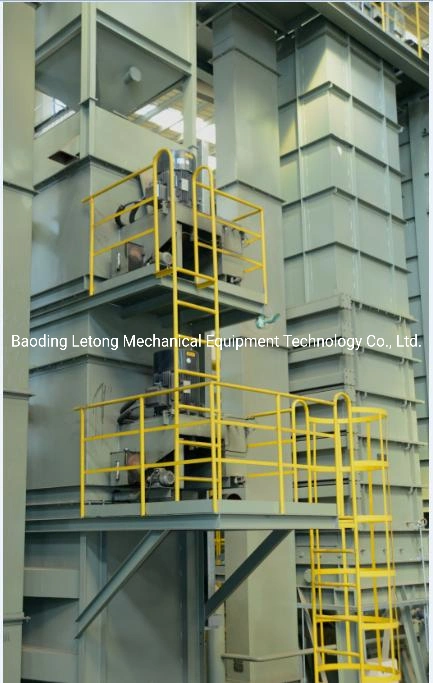

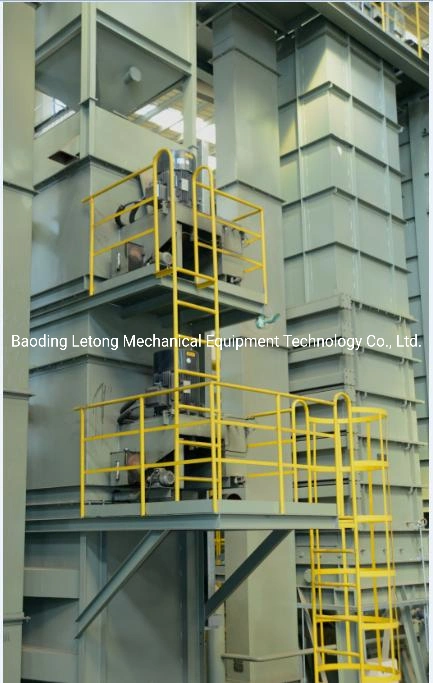

Baoding Letong Mechanical Equipment Technology Co.,Ltd is an entity specialized in R&D and production of casting equipment and integrating scientific research,design,manufacturing,installation,commissioning and technical consulting.It has decades

in R&D of casting equipment,providing advanced,reliable and practical casting equipment for the casting industry.

Bottom pouring machine is suitable for the online synchronous pouring of vertical line.Different types of pouring machine

are used for vetical,horizontal and static pressure Line

The bottom pouring machine can be divided into an insulation bottom pouring machine and a non-insulation bottom pouring machine. The bottom pouring machine is lifted up and down through the plug rod. It adopts the method of pouring molten iron from the bottom of the ladle directly into the sand mold. It is rapid and stable, and suitable for continuous pouring in the vertical parting molding automatic line, improving the efficiency of the production line and casting quality.It has the functions of

heat insulation,weighing and imaging,and is suitable for the online synchronous and rapid automatic pouring of verical

parting moudling Line.

Type of resin sand regeneration line

1. Furan resin regeneration line

2. Alkali phenolic regeneration line

Technical specification of production line(The table shows single line specifications)

in R&D of casting equipment,providing advanced,reliable and practical casting equipment for the casting industry.

Bottom pouring machine is suitable for the online synchronous pouring of vertical line.Different types of pouring machine

are used for vetical,horizontal and static pressure Line

The bottom pouring machine can be divided into an insulation bottom pouring machine and a non-insulation bottom pouring machine. The bottom pouring machine is lifted up and down through the plug rod. It adopts the method of pouring molten iron from the bottom of the ladle directly into the sand mold. It is rapid and stable, and suitable for continuous pouring in the vertical parting molding automatic line, improving the efficiency of the production line and casting quality.It has the functions of

heat insulation,weighing and imaging,and is suitable for the online synchronous and rapid automatic pouring of verical

parting moudling Line.

Type of resin sand regeneration line

1. Furan resin regeneration line

2. Alkali phenolic regeneration line

Technical specification of production line(The table shows single line specifications)

| TYPE | S524 | S528/S568 | S5212 | S5216 | S5220 |

PRODUCTION RATE(t/h) | 5 | 10 | 15 | 20 | 25 |

ANNUAL CASTING PRODUCTION (T) | 3000-5000 | 5000-8000 | 8000-10000 | 10000-20000 | 20000-30000 (IRON CASTING & SELL CASTING) |

SELF HARDENING SAND PROCESS | Alkali phenolic resin sand Esterified sodium silicate sand VRH and other self-hardening sand technology | ||||

TYPES OF CASTING | HT & QT & ALLOY IRON CASTING & SELL CASTING & ALUMINUM CATING & COPPER CASTING | ||||