Basic Info.

Model NO.

Letong42

Automation

Semi-automatic

Certification

CE, CB, ETL

Condition

New

Customized

Non-Customized

MOQ

1 Set

Quality

Good

User

Casting Foundry

Transport Package

as Per Customer Needs

Specification

0.2kg-11 tons

Trademark

letong

Origin

China

Production Capacity

100set/Year

Product Description

Baoding Letong Mechanical Equipment Technology Co.,Ltd is an entity specialized in R&D and production of casting equipment and integrating scientific research,design,manufacturing,installation,commissioning and technical consulting.It has decades

in R&D of casting equipment,providing advanced,reliable and practical casting equipment for the casting industry.

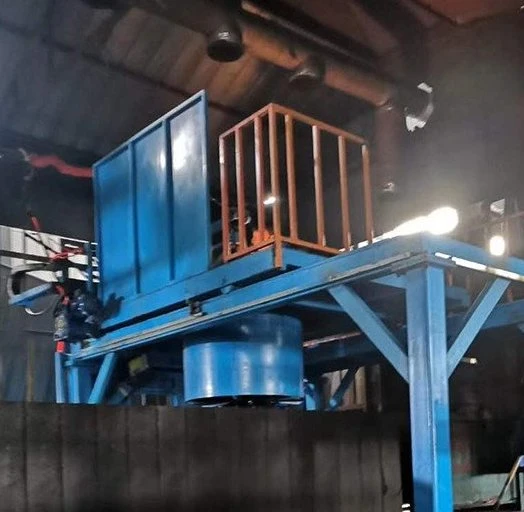

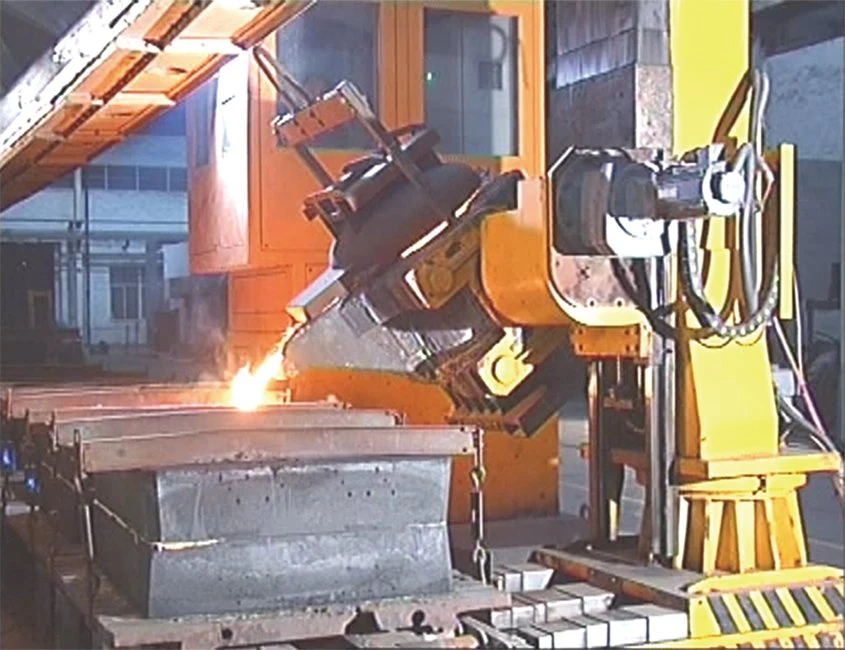

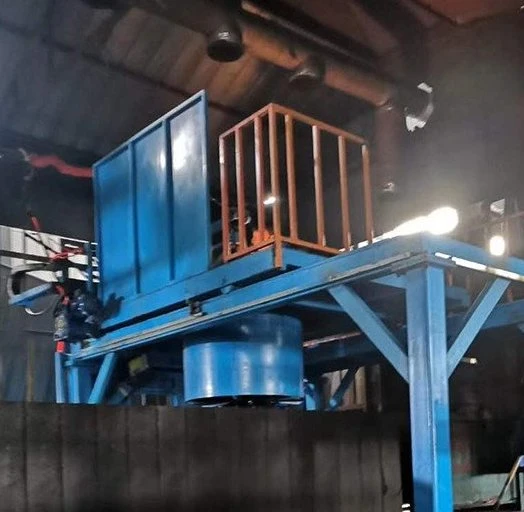

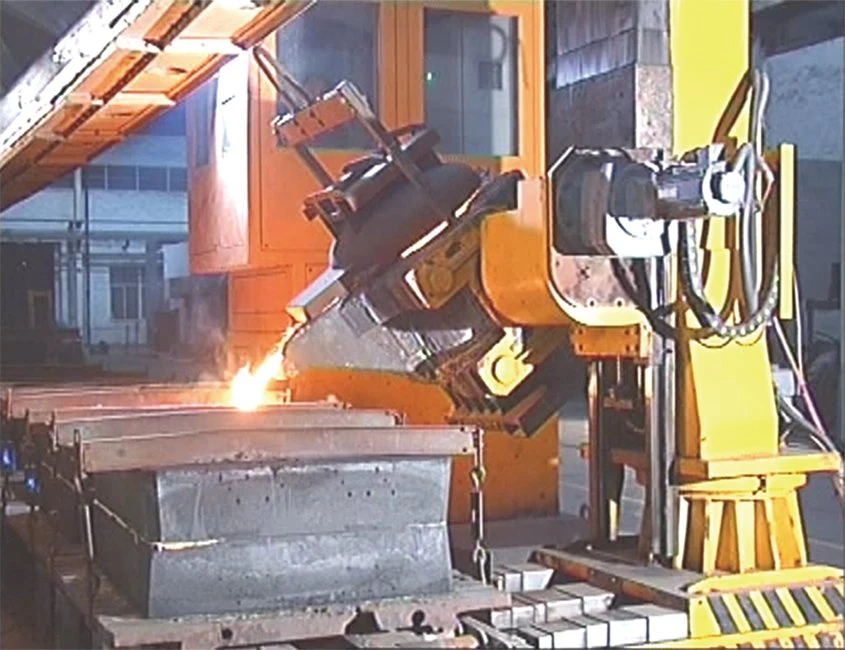

Bottom pouring machine is suitable for the online synchronous pouring of vertical line.Different types of pouring machine

are used for vetical,horizontal and static pressure Line

The bottom pouring machine can be divided into an insulation bottom pouring machine and a non-insulation bottom pouring machine. The bottom pouring machine is lifted up and down through the plug rod. It adopts the method of pouring molten iron from the bottom of the ladle directly into the sand mold. It is rapid and stable, and suitable for continuous pouring in the vertical parting molding automatic line, improving the efficiency of the production line and casting quality.It has the functions of

heat insulation,weighing and imaging,and is suitable for the online synchronous and rapid automatic pouring of verical

parting moudling Line.

Technical parameters

in R&D of casting equipment,providing advanced,reliable and practical casting equipment for the casting industry.

Bottom pouring machine is suitable for the online synchronous pouring of vertical line.Different types of pouring machine

are used for vetical,horizontal and static pressure Line

The bottom pouring machine can be divided into an insulation bottom pouring machine and a non-insulation bottom pouring machine. The bottom pouring machine is lifted up and down through the plug rod. It adopts the method of pouring molten iron from the bottom of the ladle directly into the sand mold. It is rapid and stable, and suitable for continuous pouring in the vertical parting molding automatic line, improving the efficiency of the production line and casting quality.It has the functions of

heat insulation,weighing and imaging,and is suitable for the online synchronous and rapid automatic pouring of verical

parting moudling Line.

Technical parameters

| CONTENT | TECHNICAL PARAMETERS | |

| Maximum cleaning workpiece weight one time | 1200 kg | |

| Unit max weight | 20kg | |

| Maximum single piece length | 400 mm | |

| abrasive impeller | diameter | φ450 mm |

| maximum shot blasting capacity | 250 kg/min | |

| motor power | 22 kw | |

| elevator | maximum lifting capacity | 30000 kg/h |

| belt speed | 1.22m/s | |

| power | 2.2kw | |

| Sieve drum | productivity | 30000kg/min |

| power | 1.5KW | |

| | Pellet material separation type | winnowing |

| Wind selection dimension | 0.09m2 | |

| blast capacity | 2950m3/h | |

| | Rotary speed | 4.5rpm |

| motor power | 2.2KW | |

| chain block | Motor power | 3.7KW |

| carrying capacity | 2.5T | |

| hydraulic pressure station | Motor power | 5.5kw |

| dust catcher | Ventilation capacity | 9000m3/h |

| power | 7.5kw | |