Basic Info.

Model NO.

GW-3T-2500KW/0.6S

Inlet Power Voltage

380V

Power Resonant

Series Resonant Invertion

Connection

Wide T2 Red Copper

Power Cabinet

Compact

Cabinet Color

Customized

Furnace Body

Steel Sheel

Furnace Structure

One-Piece Casting

Magnetic Yoke

High Permeability

York Type

Waterless

Induction Coils

Porcelain Insulated

Coils Type

Tu1 Oxygen Copper

Leakage Alarm

Automatic

Cooling Type

Water Cooling

Cooling System

Closed Internal Circulation

Customized

Provide

Transport Package

Seaworthy Packaging

Specification

2500KW, 3000KG Capacity

Trademark

Liuxingke Brand

Origin

China

HS Code

8514200090

Production Capacity

600 Sets Per Year

Product Description

Series resonance MF induction furnace for melting iron scrap

Melting Capacity :3000KG

GW-3T-2500KW/0.6S

The complete set of induction furnace components include:

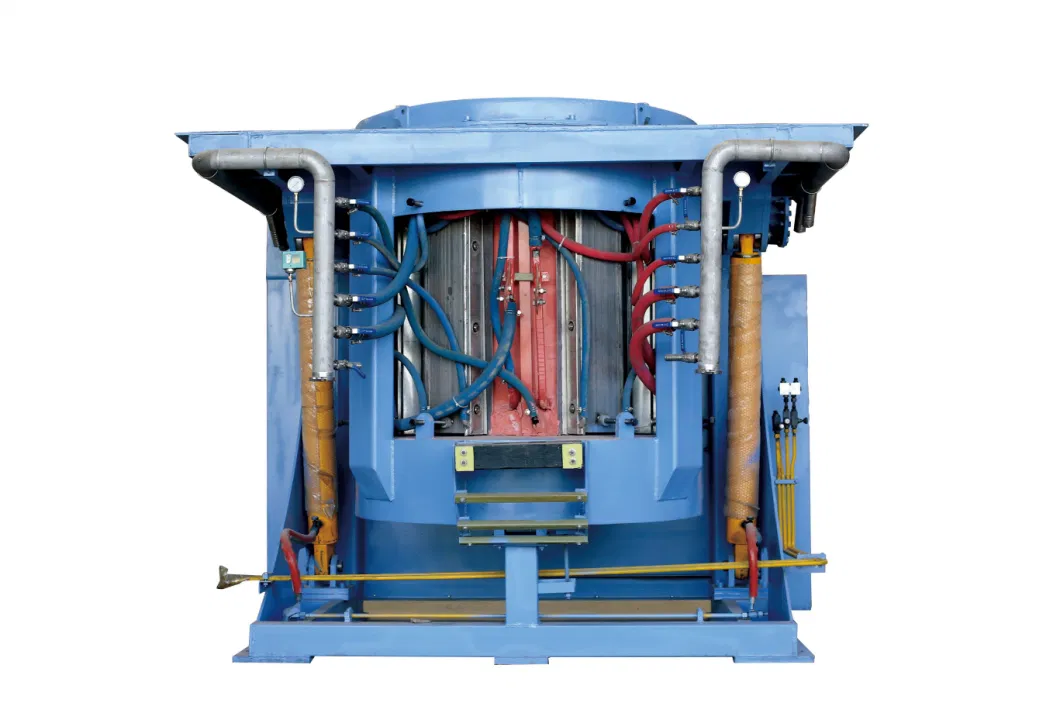

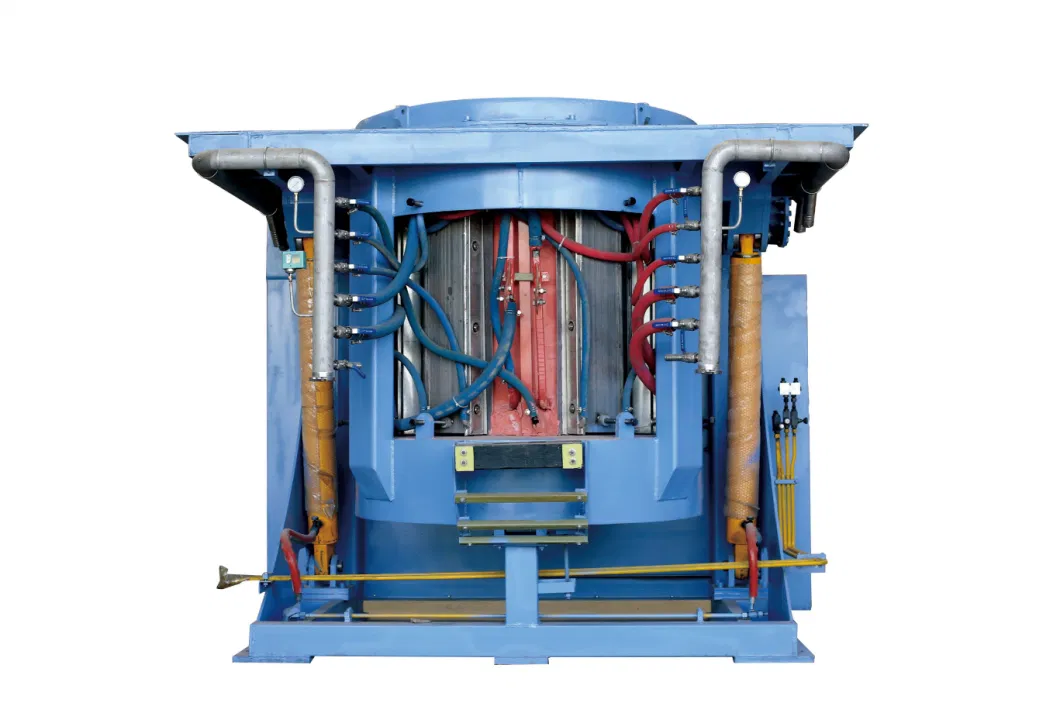

Steel shell furnace body

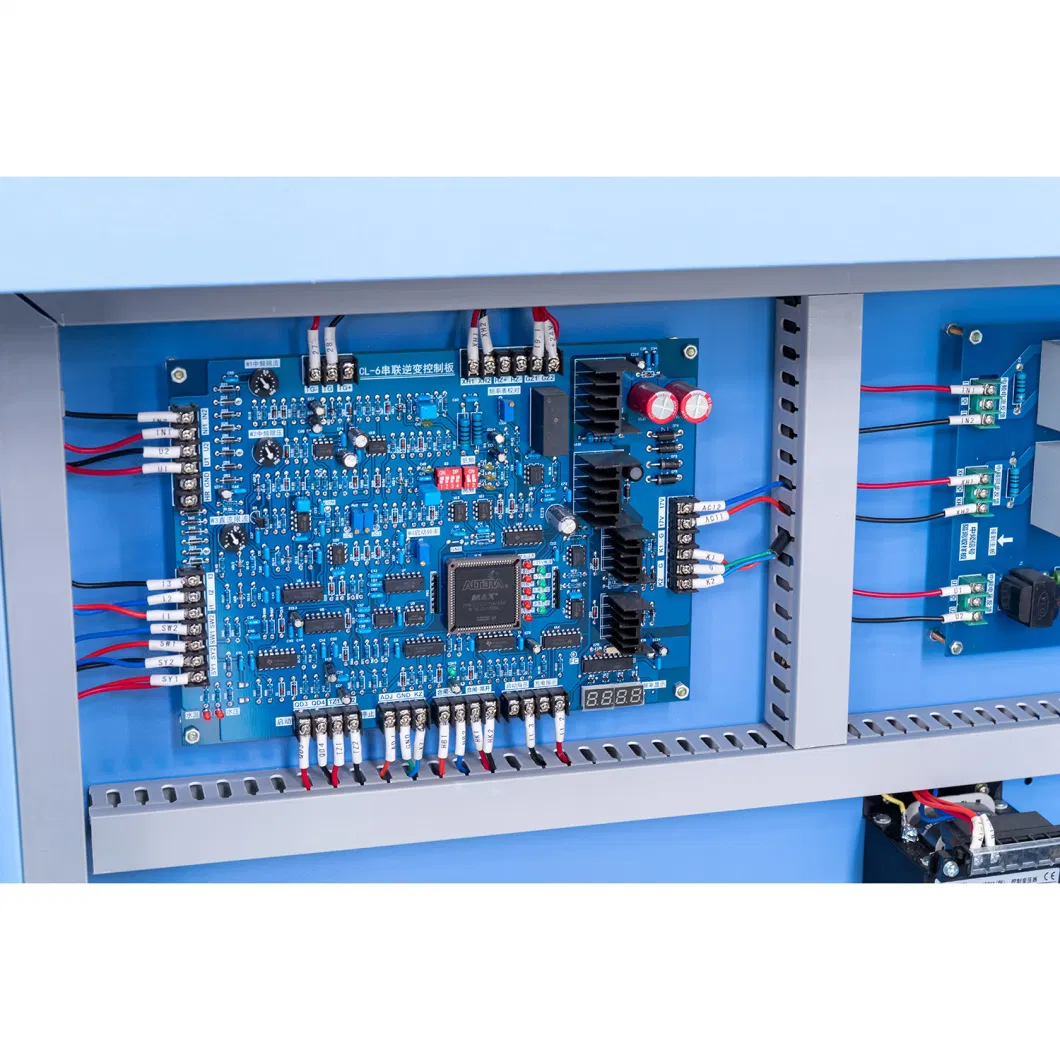

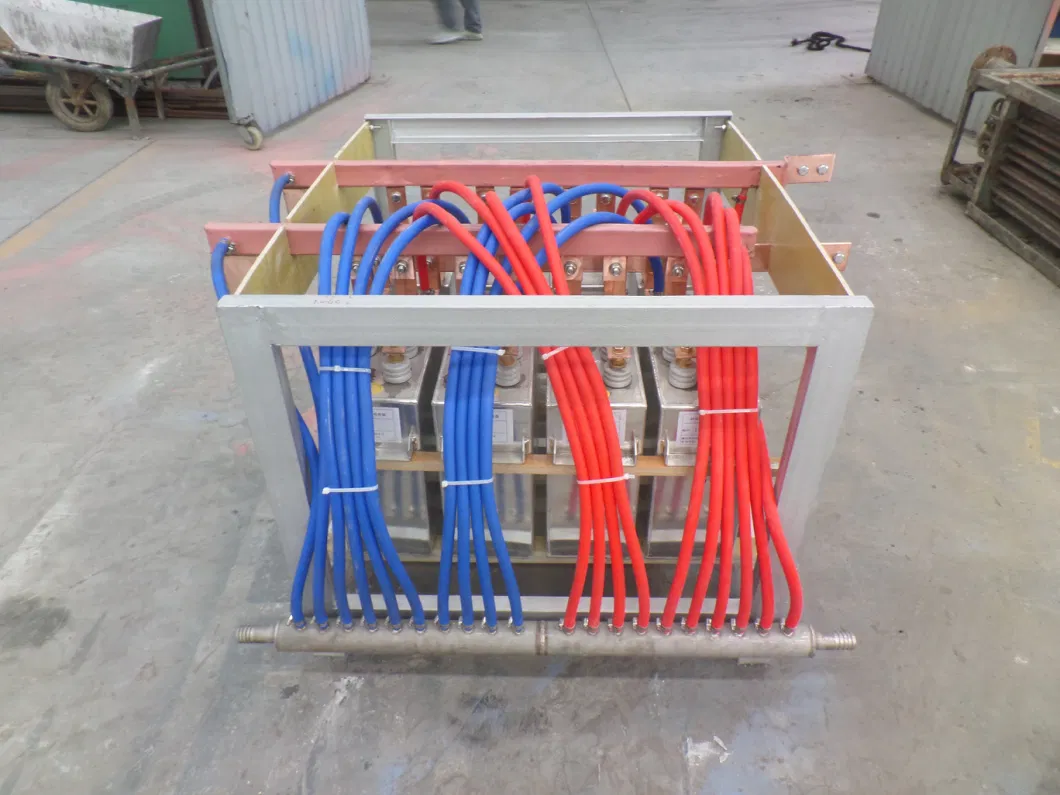

Converter Cabinet

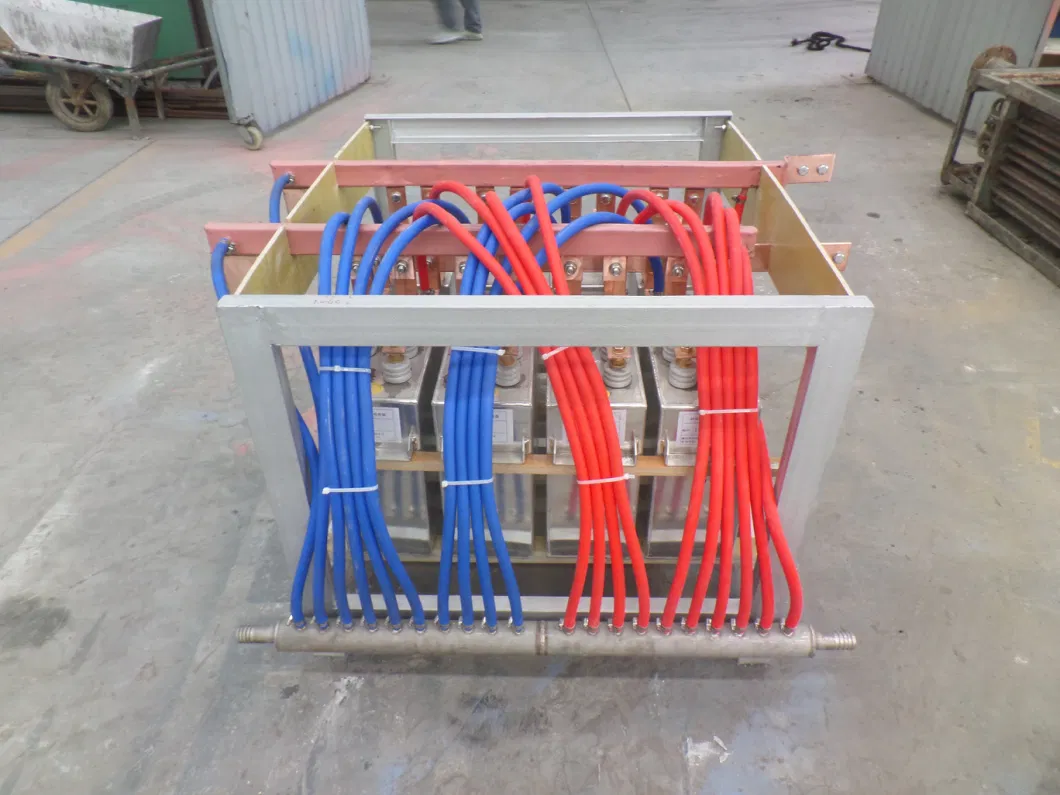

Capacitor

Hydraulic pumping unit

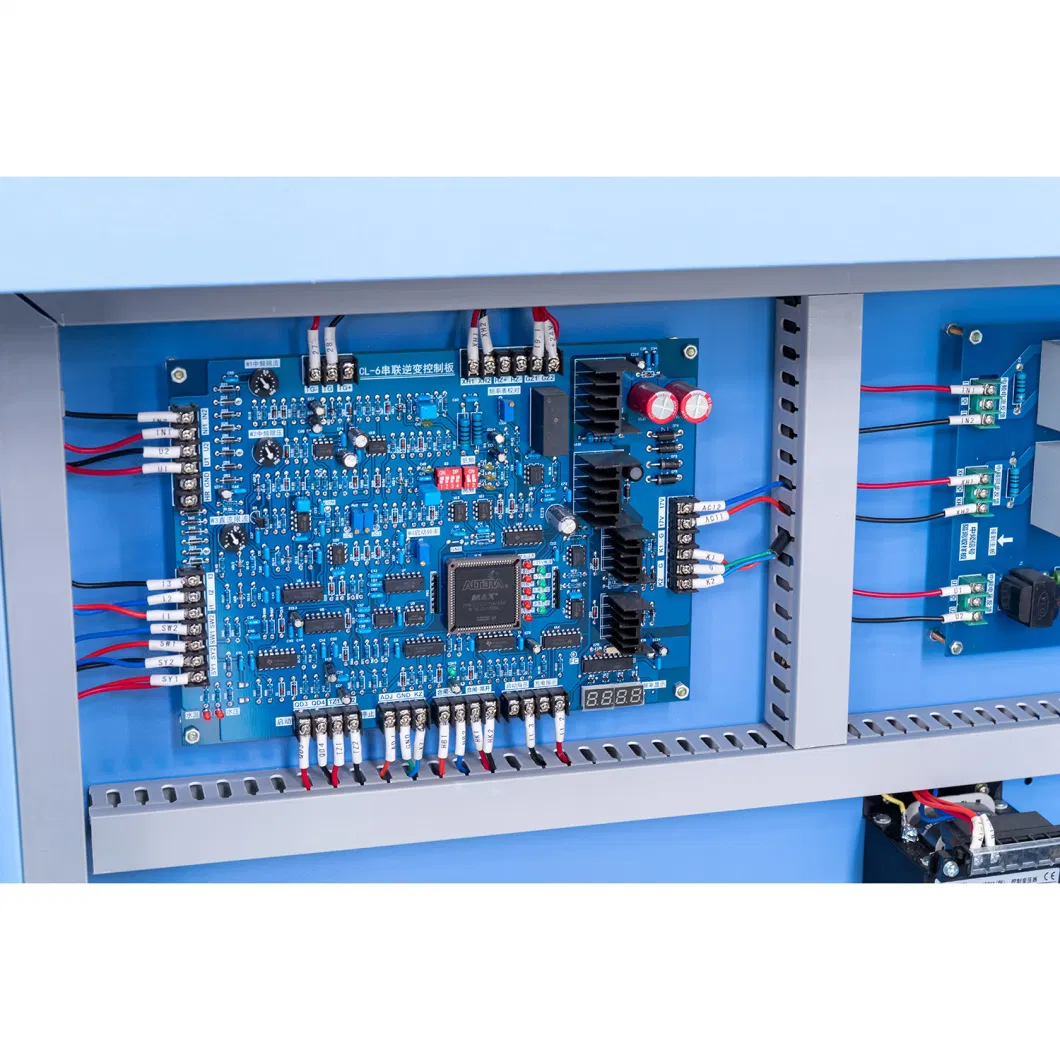

Control board

Complete steel shell furnace body

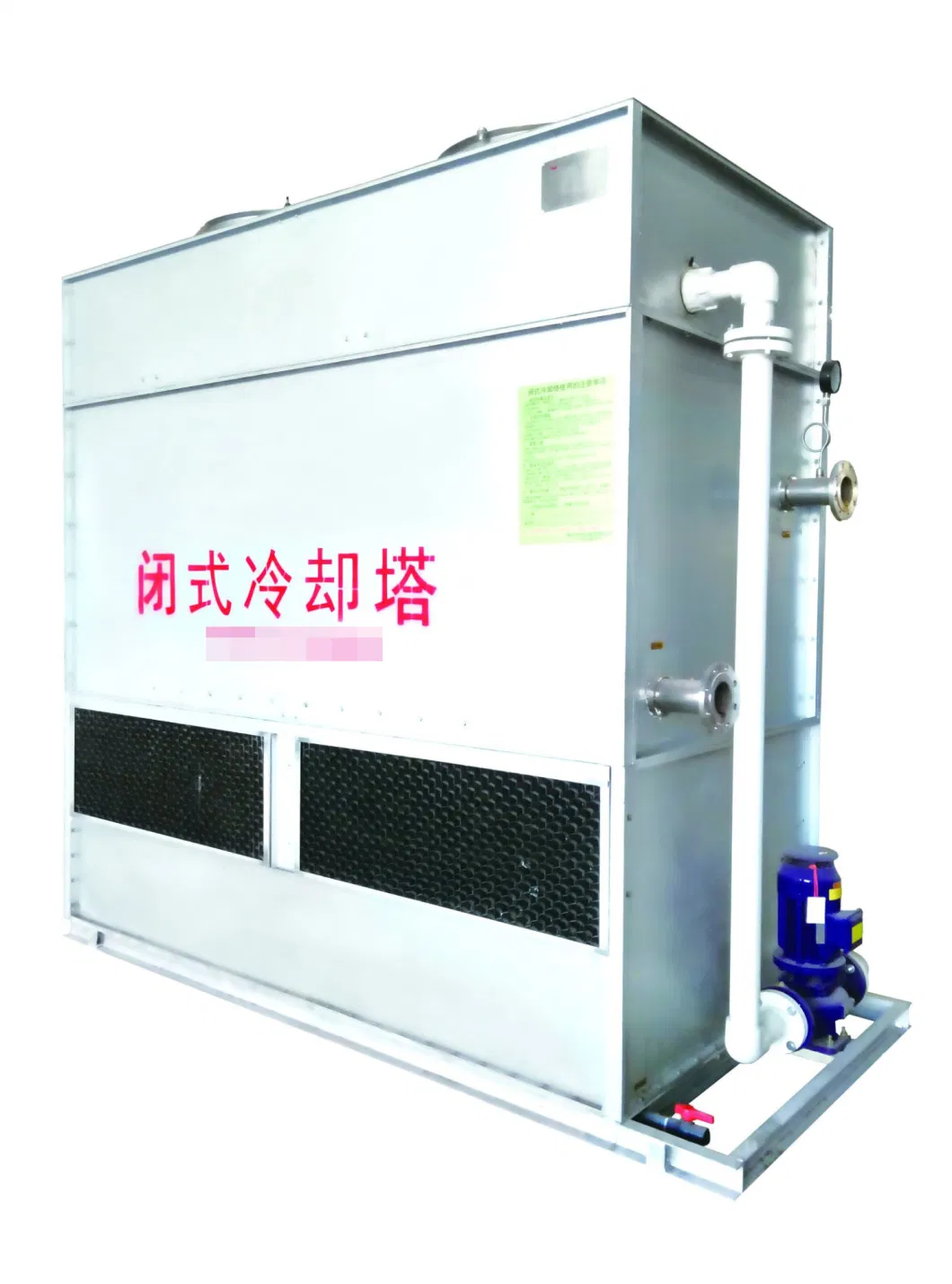

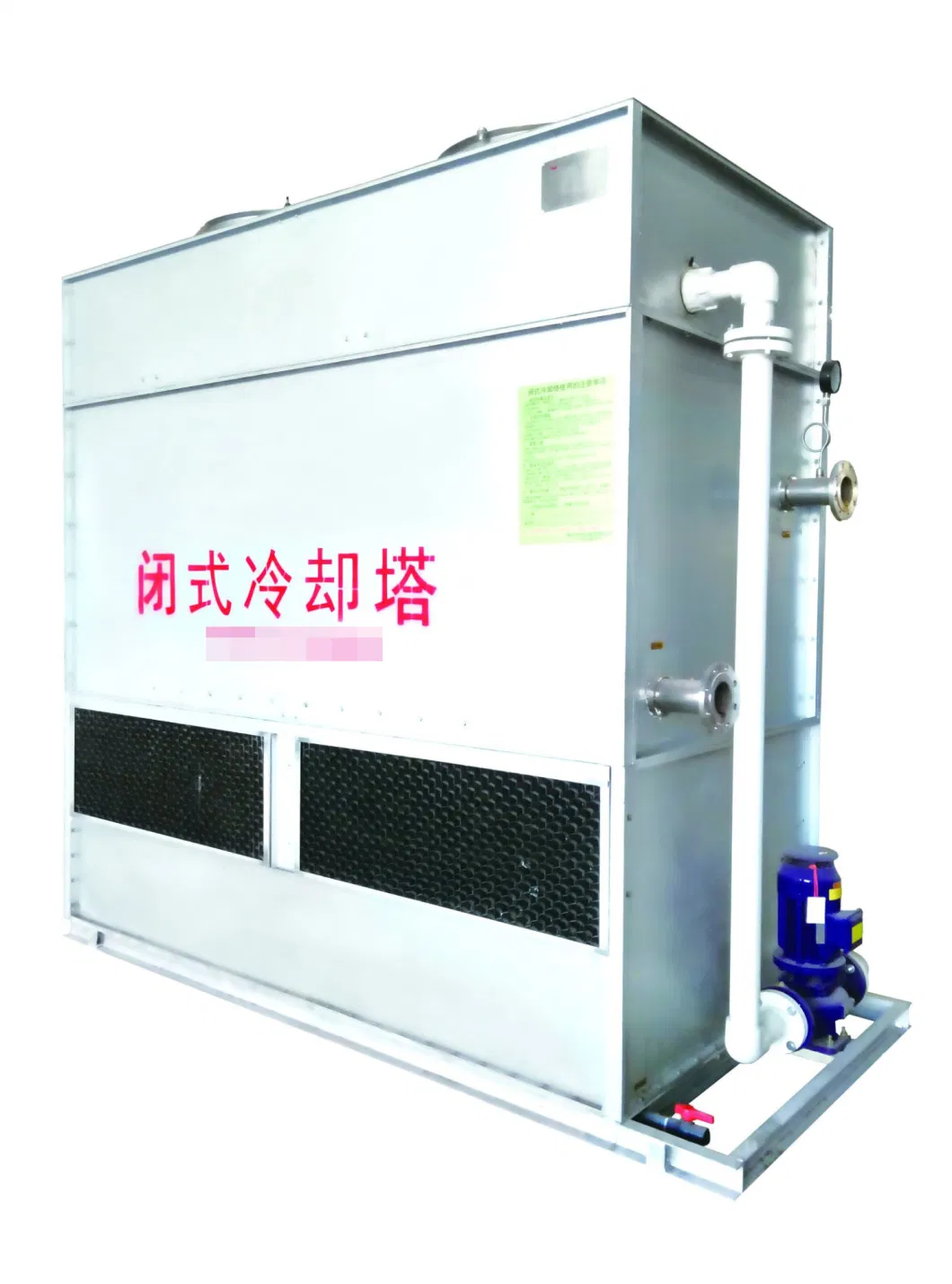

Closed water cooled equipment

Trade terms

1. Delivery Port : Qingdao

2.Lead time: 30 days in low season, 60-90 days in peak season

3.Shipment: 20GP/40GP/40HC/40OT/Flat rack container,According to the situation

4.Payment terms:

4.1)By T/T, 50% in advance , 50% balance before shipment

4.2)By T/T + L/C , 50% by T/T in advance , 50% by 100% irrevocable L/C opened by famous Bank

4.3)By L/C , 100% Confirmed irrevocable L/C opened by famous Bank

After sale service:

1.Quality Guarantee: 1 year.

2.Commissioning: We send technicians to the site to provide installation and commissioning services.

3.During the warranty period, provide accessories, free of charge .

4.After the warranty period, provide accessories in time and guide installation and commissioning

Melting Capacity :3000KG

GW-3T-2500KW/0.6S

| Sr. No. | Description | Rating |

| 1. | Rated Power (KW) | 2500 |

| 2. | Melting power (KW) | 2500 |

| 3. | Melting Temperature (°C) | 1550 |

| 4. | Melting time | 55±5 min |

| 5. | Input Power Factor | 0.95 |

| 6. | Input Voltage (Volts) | 380 |

| 7. | Output Frequency (Hz) | 600 |

| 8. | Output Voltage (Volts) | 3000 |

| 9. | Nominal capacity of furnace in Kg for Iron(kg) | 3000 |

| 10. | Maximum capacity of the furnace in Kg for Iron (kg) | 3500 |

| 11. | Melting Rate for Iron at 1550° C at 3000KW (Kg/Hr) | 3000 |

| 12. | Control method: Intelligent PLD power control system | Yes |

| 13. | Lining material | Yes |

| 14. | Energy consumption per ton for iron | 550KW.H±5% |

| 15. | Double rectifier transformer model | ZP-2500KVA/10KV/ 0.575KV *2 |

| 16. | Multi-protections: overcurrent, overpressure or underpressure, water pressure, phase loss, furnace leak alarm and water temperature alarm | Yes |

The complete set of induction furnace components include:

| Item | Product Name | Model | QTY | Unit | |

1 | MF Power Supply | KGPS series resonance power supply | KGPS-CL-2500-0.6S | 1 | Set |

| Coreless reactor | DK-2500 | 1 | Set | ||

| Filter capacitor cabinet | KH-2500KW-LB | 1 | Set | ||

| Resonant capacitor cabinet | KH2500KW-XZ | 1 | Set | ||

| Connecting copper bar | T2 (power supply to capacitor cabinet) | 1 | Set | ||

| 2 | Furnace body (steel shell with yoke) | Furnace Pot | 3T | 1 | Set |

| Furnace frame | 3T | 1 | Set | ||

| Hydraulic Cylinder | 3T | 1 | Set | ||

| Sensor | 3T | 1 | Set | ||

| Crucible | 3T | 1 | Pcs | ||

| Insulating margin mortar | 1 | Set | |||

| Water-cooled cable | T2 red copper (2 pcs 1 set) | 1 | set | ||

| Cyclone dust cover | XF-3000 | 1 | set | ||

| Security Fence | Automatic lifting | 1 | Set | ||

| 3 | Hydraulic system | Hydraulic station | Excluding hydraulic oil, including high-pressure tubing (Double pumps, one use and one backup) | 1 | Set |

| Furnace tilting hydraulic console | Including hydraulic control system | 1 | Set | ||

| Furnace leaking alarm system | 1 | Set | |||

| 4 | enclosed water cooling system | Power supply closed water cooling | HL-750 | 1 | Set |

| Furnace body closed water cooling | HL-1500 | 1 | Set | ||

| 5 | Installation materials | Stainless steel pipes, valves, brackets, etc. | 1 | batch | |

| 6 | Transformer | Zp-2500KVA/10kv/0.575kv*2 | 1 | Set | |

| 7 | Connecting copper bar | Maximum length of one piece is 6 meters | From transfer to power supply | 36 | M |

Steel shell furnace body

Converter Cabinet

Capacitor

Hydraulic pumping unit

Control board

Complete steel shell furnace body

Closed water cooled equipment

Trade terms

1. Delivery Port : Qingdao

2.Lead time: 30 days in low season, 60-90 days in peak season

3.Shipment: 20GP/40GP/40HC/40OT/Flat rack container,According to the situation

4.Payment terms:

4.1)By T/T, 50% in advance , 50% balance before shipment

4.2)By T/T + L/C , 50% by T/T in advance , 50% by 100% irrevocable L/C opened by famous Bank

4.3)By L/C , 100% Confirmed irrevocable L/C opened by famous Bank

After sale service:

1.Quality Guarantee: 1 year.

2.Commissioning: We send technicians to the site to provide installation and commissioning services.

3.During the warranty period, provide accessories, free of charge .

4.After the warranty period, provide accessories in time and guide installation and commissioning