Basic Info.

Model NO.

CF-044

Surface Treatment

Sand Blast

Surface Roughness

Ra6.3

Standard

ANSI

Certification

CE, ISO 9001:2008

Package

Pallet ,Manmade Wooden Case or as Your Requirement

Certificate

ISO 9001 SGS

Origine

Qingdao

Service

OEM and ODM

Brand

Chifine

Delivery Time

30 Days After Receiving The Payment

Supply Ability

1500tons Per Month

Material Type

Grey Iron

Machining Type

CNC Tunring Milling Drilling Lathe

Heat Treatment

Normalizing ,Tempering ,Quenching .Anealling

Transport Package

in Pallet or as Your Requirment

Specification

ISO9001 SGS CE

Trademark

Chifine

Origin

Jimo Qingdao City

HS Code

7325101000

Production Capacity

1000tons Per Month

Product Description

Details of the product:

1. Material & Standard: Grey iron, ductile iron, malleable iron, carbon steel, alloy steel(high Manganese steel, high Chromium steel and others), Stainless steel, Aluminum alloy, Copper alloy;

JIS, DIN, BS, GB, ASTM.

2. Moulding processing: Green sand, Resin sand, Waterglass sand, Lost wax/Silicon sol or Die casting.

3. Melting facilities: Cupola furnace, medium frequency induction electric furnace or electric arc furnace.

4. Casting Inspection facilities: Direct-reading spectrum instrument, metallographic analysis, magnetic particle inspection, ultrasonic inspection, X-ray inspection, mechanical properties inspection.

5. Heat treatment facilities: Aging oven, Electric furnace, Normalizing, Quenching and Tempering equipments.

6. Surface treatment: Shot blast cleaning, polishing, Chrome plating, Zinc plating, powder coating and others.

7. Machining facilities: CNC centres, NC lathes, NC milling machines, NC boring machines, drilling machines and other common machines.

8. Inspection facilities: CNC 3-D inspecton facilities and others.

9. Industrial categories: Tractor, Heavy-duty truck industry, Car industry, Farm machinery, Construction

Engineering machine industry, Electricity power industry, Elevator industry, Valve industry, General machine industry and others.

Part Unit weight range:

For grey iron casting: Up to 15000kgs;

For ductile iron casting: Up to 4000kgs;

For high manganese steel casting: Up to 5000kgs;

For carbon steel & alloy steel casting: Up to 10000kgs;

For Aluminum/copper alloy die casting: From 8g up to 12kgs;

For Investment/lost wax casting: Up to 80kgs;

Machining Ability

Our machining shop located in Qingdao using the latest CNC equipment to provide our customer with high quality products.

Horizontal and Vertical Machining Center

CNC lathe and normal lathe

CNC drilling and milling Center

Other assistant equipment

Product Design and casting simulation

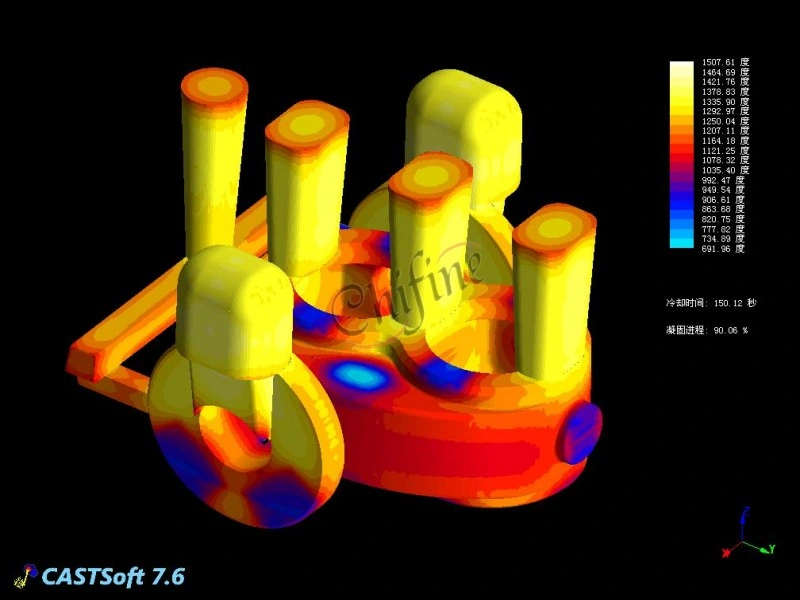

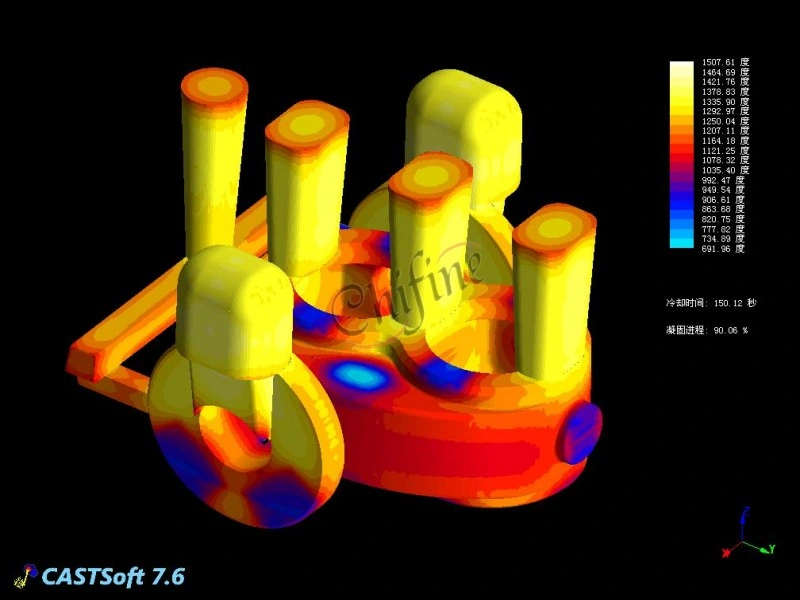

Successful parts are original from successful design. We own high level engineers on the product design. They are good at make drawing using the software of CAD. PROE, SOLIDWORKS for assuring production process well.

Our technical group have rich experience in casting process, so we can put forward reasonable suggestions to the product structure design on various performance, process parameters to solve the customer's requirement, set up the 3D model, get the results from pouring simulation analysis. Then modify and optimize the scheme to determine the correct casting

1. Material & Standard: Grey iron, ductile iron, malleable iron, carbon steel, alloy steel(high Manganese steel, high Chromium steel and others), Stainless steel, Aluminum alloy, Copper alloy;

JIS, DIN, BS, GB, ASTM.

2. Moulding processing: Green sand, Resin sand, Waterglass sand, Lost wax/Silicon sol or Die casting.

3. Melting facilities: Cupola furnace, medium frequency induction electric furnace or electric arc furnace.

4. Casting Inspection facilities: Direct-reading spectrum instrument, metallographic analysis, magnetic particle inspection, ultrasonic inspection, X-ray inspection, mechanical properties inspection.

5. Heat treatment facilities: Aging oven, Electric furnace, Normalizing, Quenching and Tempering equipments.

6. Surface treatment: Shot blast cleaning, polishing, Chrome plating, Zinc plating, powder coating and others.

7. Machining facilities: CNC centres, NC lathes, NC milling machines, NC boring machines, drilling machines and other common machines.

8. Inspection facilities: CNC 3-D inspecton facilities and others.

9. Industrial categories: Tractor, Heavy-duty truck industry, Car industry, Farm machinery, Construction

Engineering machine industry, Electricity power industry, Elevator industry, Valve industry, General machine industry and others.

Part Unit weight range:

For grey iron casting: Up to 15000kgs;

For ductile iron casting: Up to 4000kgs;

For high manganese steel casting: Up to 5000kgs;

For carbon steel & alloy steel casting: Up to 10000kgs;

For Aluminum/copper alloy die casting: From 8g up to 12kgs;

For Investment/lost wax casting: Up to 80kgs;

Machining Ability

Our machining shop located in Qingdao using the latest CNC equipment to provide our customer with high quality products.

Horizontal and Vertical Machining Center

CNC lathe and normal lathe

CNC drilling and milling Center

Other assistant equipment

Product Design and casting simulation

Successful parts are original from successful design. We own high level engineers on the product design. They are good at make drawing using the software of CAD. PROE, SOLIDWORKS for assuring production process well.

Our technical group have rich experience in casting process, so we can put forward reasonable suggestions to the product structure design on various performance, process parameters to solve the customer's requirement, set up the 3D model, get the results from pouring simulation analysis. Then modify and optimize the scheme to determine the correct casting

PROCESS | MATERIAL | |

SAND CASTING | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stainless Steel, Carbon, Steel, Aluminium,Brass,Bronze |

Furan Resin Sand | ||

Cold Harden Resin Sand | ||

INVESTMENT CASTING | Sodium Silicone (Water glass) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum |

Silica Sol | ||

FORGING | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum |

Die Forging | ||

Roll Forging | ||

STAMPING MACHINING | STAMPING MACHINING | All metal material |