- Overview

- Product Parameters

- Our Material

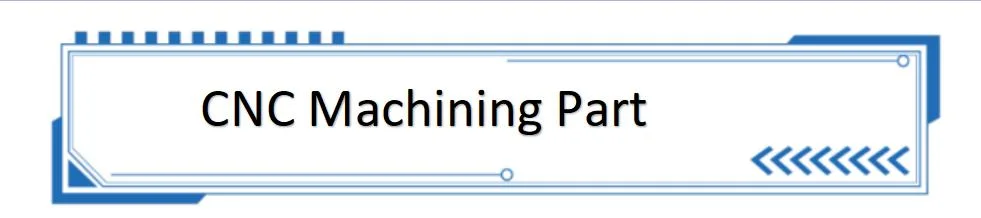

- Mail Product

- Company Profile

- Our Equipment

- Packaging & Shipping

- Application

- FAQ

Basic Info.

Product Description

| Material & Temper | Aluminium alloy ADC12, A380 or customized. |

| Film Standard | Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Thickness | 0.4-20mm, or customized. |

| Surface Treatment | Polishing, Brushing, Mill-finished, Powder-coating, etc. |

| Applications | Industry fittings, construction and decoration. |

| Deep Processing | CNC / Cutting / Milling / Turning / Drilling / Tapping / Punching |

Plastic: ABS, POM, PC, PP, PPS, PMMA, HDPE, PEEK, Nylon, etc.

These are the most common materials that suitable for CNC prototyping and production parts.

There's wide options for surface finish such as: Anodizing, Powder coating, Spray coating, Electroplating, Brushing, Polishing, as machined and so on.

QiJia Precision Cooperates with domestic and foreign brand original manufacturers to optimize materials to ensure product quality and increase product life. At the same time, all materials can provide certification documents. Material available, such as aluminum alloy, steel alloy, stainless steel, copper, brass, titanium, Bronze, Nylon, Acrylic etc.

Alu 6061/6063/7075; Iron 1215/45/1045; Stainless steel 303/304/316; Copper; Brass; Bronze(H59/H62/T2/H65); Plastic POM/PE/PSU/PA/PEK etc. as customer's request.

Dongguan QiJia Precision Technology Co., Ltd (QJ) located in Guangdong, China, factory equipped with 6 zinc alloy die-casting machines (capacity 50-160Tons), 4 aluminum alloy die-casting machines (capacity 280-500Tons), and advanced multi-axis CNC machining centers.

We provide die casting service and high precision custom CNC machining services to global customers. Rapid delivery, cost effective and high & stable quality are our advantages.

.CNC machining center . CNC milling machine .CNC turning machine

.CNC punching machine .Surface grinder, Inside & outside round grinder

.Die-casting machine .Electric spark machine

All the parts from QiJia Precision are widely used in medical, electronic gadgets, electrical appliances, furniture, building, toys, motor cycles, racing cars, machine parts, kitchenware, sport equipment, music instruments, robots, machinery and many other fields.

1.Q: Are you trading company or manufacturer ?

A: We are direct factory with experienced engineers and employees as well as well-organized workshop.

2.Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, the sample fee depends on the product geometry, and the fee will be returned to your bulk order.

4.Q: How long can I get the sample?

A: Depends on your part geometry, normally within 3-7 days.

5.Q: How long is your delivery time?

A: Sample 3-7days; Mass production order 7-45 days depends on quantity and part complexity.

6.Q: What shall we do if we do not have drawings?

A. Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Length, Height, Width), CAD or 3D file will be made for you if placed order.

7.Q: Will my drawings be safe after sending to you?

A: Yes, we can sign the NDA before got your drawing and will not release to the third party without your permission

8.Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which

show the machining progress

9.Q: How to enjoy the OEM services?

A: Usually, base on your design drawings or original samples, we give some technical proposals and a quotation

to you, after your agreement, we produce for you.