- Overview

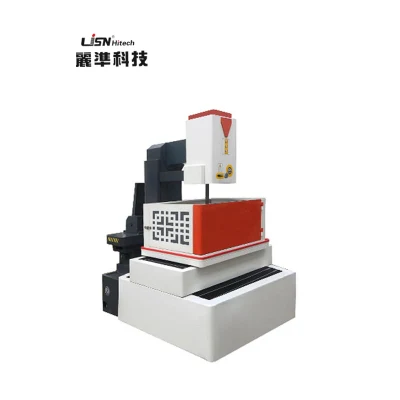

- Product Description

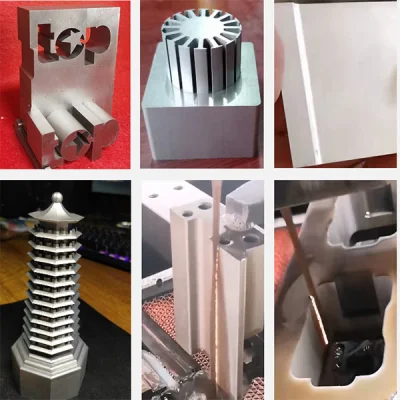

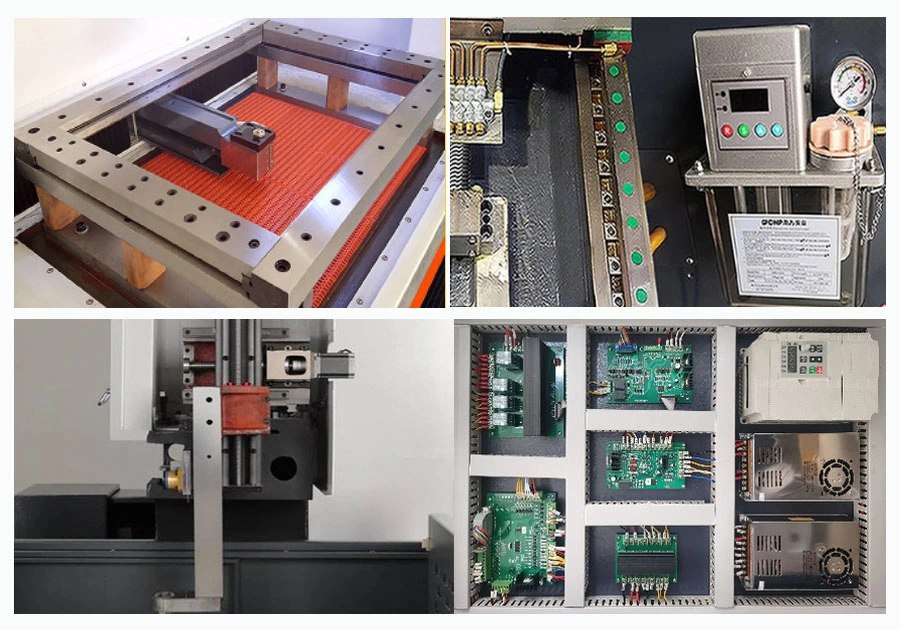

- Detailed Photos

- Product Parameters

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

1.The machine tool adopts classic integrated design, with beautiful shape, novel structure, superior performance, free adjustment of the position and orientation of the operating platform, and convenient operation.

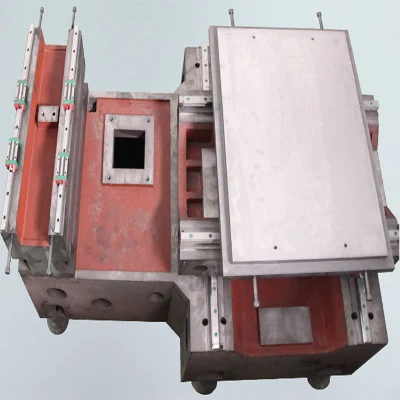

2. The bed adopts resin sand casting technology to cast high strength cast iron, T-shaped bed structure (slow wire body structure) to ensure the mechanical accuracy is constant.

3. The XY axis adopts Japan's Yaskawa AC servo system to achieve zero position setting and closed-loop control of pitch compensation, and improve the positioning accuracy and processing accuracy of the machine tool.

4.The feed direction of the machine tool adopts Taiwan Shangyin linear guide rail and high-precision ball screw, which ensures the rapid response of the machine tool and improves the positioning accuracy of the machine tool.

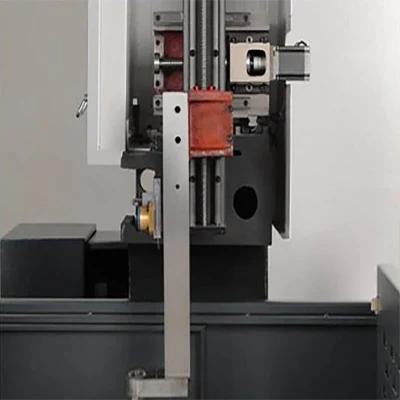

5. The wire conveying mechanism adopts Taiwan Shangyin linear guide rail as the moving part, and the frequency converter control technology can ensure smooth operation at both high speed and low speed.

6. The "C" type structure wire frame and lifting wire guide die (Z axis) can realize veneer processing, effectively prevent the molybdenum wire from shaking, avoid the cutting surface line marks, and facilitate the lifting and removal of waste materials during processing.

7.The automatic lubrication system is controlled by an independent PLC, which automatically distributes the amount of oil, reduces the waste of lubricating oil, and avoids the reduction of the life of the lead screw and line rail due to the lack of lubricating oil.

8.The multi-filter working fluid system improves the cleanliness and slag removal performance of the working fluid, extends the service life of the working fluid, and improves the discharge effect and surface finish.

9. All transmission shafts of the machine tool are checked, optimized and compensated by laser interferometer to ensure that the accuracy of the machine tool conforms to various technical indicators of the latest national and industrial standards for wire feeding.

10.Windows embedded control system realizes the integration of CAD/CAM, that is, highly integrated and independent interface control, and improves work efficiency.

10. With powerful Ethernet communication function, it can realize network centralized control, information monitoring and file transmission of all equipment, interface with factory ERP system, and respond to National Industry 4.0.

11. The system has an intelligent database. Users can automatically match the process parameters as long as they provide the material type, material thickness, wire diameter, cutting times and other conditions, especially for beginners.

12. Manual control box operation, switch wire transportation, water pump, high frequency, shaft shift, simulation, processing, tool centering, and handwheel function make the operation convenient.

13. AR function, the workpiece placement does not need to be calibrated by a table, and the placement angle is determined by two points or two holes on the reference plane. After setting the AR angle, the movement and processing will be carried out automatically according to the placement angle.

Main Features

- Select paired clearance-free bearings to improve accuracy.

- Selection of high quality ball screw

- Using steel-inlaid guide rail

- Good assembly process requirements

- By using frequency converter, the speed of the wire drum can be adjusted arbitrarily, thus improving the smoothness of the workpiece

| Specification & Models | MS-650AC |

| Worktable Travel (X,Y) | 600X500mm |

| Worktable (WxD) | 920X680mm |

| Working Tank Dimensions(W x D x H) | 1150x830x450mm |

| Taper Axis Travel (U, V) | 60x60mm |

| Maximum Cut Taper | 6°/80mm |

| Z Axis Travel | 280/380mm |

| Maximum Workpiece Thickness | 300/400mm |

| Maximum Workpiece Weight | 1000kg |

| Speed of Electrode Wire (group wire) | 1.18-11.18m/s |

| Diameter of Electrode Wire (group wire) | 0.16-0.22mm |

| Tension of Electrode Wire (wire group) | 10-30N |

| Positioning Accuracy | 0.015mm |

| Repositioning Accuracy | 0.008mm |

| Machining Accuracy | ±0.004mm |

| Power Supply | 380V50/60Hz2.0KVA |

| Max Work Current | 10A |

| Maximum Cutting Speed | ≥280mm²/min |

| Tank Size | 130L/870x470x320mm |

| Control Cabinet Size | 580x580x1860mm |

| Machine Dimension | 1950x1650x2100mm |

| Machine Weight | 2500kg |

1. Is it all right to make customer's own brand name?

A: yes. we are available with OEM

2. Are you a manufactuer or trading company?

A:We are the manufacturer

3. Can you do the design for us?

A: yes. if you want a different control system design or higher column , we are available.

4 . What is your terms of delivery?

A: FOB shenzhen.

5. What's your payment term?

A: T/T OR L/C at sight.