Basic Info.

Model NO.

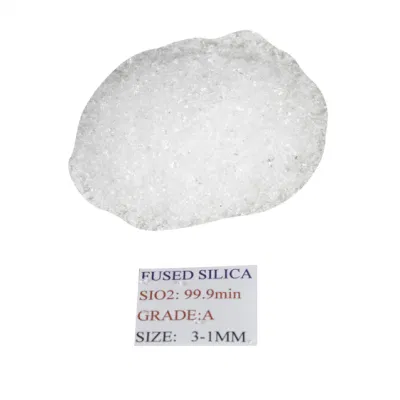

Fused Silica Sand

Coefficient of Thermal Expansion

0.1

Transport Package

PP Bag or Paper Bag.

Specification

3-1mm

Trademark

Sainuo

Origin

China

HS Code

3207400000

Production Capacity

10000piecs/Year

Product Description

Fused Silica First Grade (also known as A)

High purity quartz stone in Lianyungang and Xuzhou area was selected as raw material. After pickling treatment, the crystalline silica was transformed into amorphous silica with a small amount of impurity at 1800ºC high temperature in the resistance furnace. After special mechanical processing, screening, iron removal after the formation of blocks, particles and powder products.

Fused Silica First Grade

I. Characteristics

1. Near zero thermal expansion, extremely low thermal conductivity.

2. Excellent thermal stability.

3. High purity (the SiO2 content is above 99.95%).

4. Chemical properties are stable.

5. Special machinery production, particle size close to circular, large packing density, stable particle size distribution.

II. Basic Parameters

Density :2.2 g/m3

Hardness :7

Softening point :1700°C

Melting point :1750°C

Coefficient of thermal expansion :0.1

PH value :6

III. Chemical Composition

| Typical Values | |

| SiO2: | 99.95% |

| Al2O3: | 140ppm |

| Fe2O3: | 20ppm |

| Na2O: | 25ppm |

| K2O: | 25ppm |

| TiO2 | 16ppm |

| CaO: | 18ppm |

| MgO: | 10ppm |

IV. Availability Specifications

1. Block 0-60 mm

2. Granular

| 8-5mm | 5-3mm | 3-1mm | 1-0mm |

| 4-20 mesh | 50-100 mesh | 100-200 mesh | |

| 10-20 mesh | 20-40 mesh | 40-70 mesh |

70-140 mesh, 200 mesh, 325 mesh, 500 mesh, 1500 mesh, 3000 mesh

Company Information:

Xuzhou sainuo quartz Co., Ltd. is located in Xinyi City, Jiangsu Province town, is a company specializing in the production of fused quartz of private technology companies. Polysilicon crucible with fused silica level, fused silica nozzle with fused quartz secondary, unshaped refractory materials used fused quartz secondary and a variety of refractory materials with a fused quartz, whether all the technical indicators and the real application effect at home and abroad are first-class products, products in the domestic and international have achieved good performance, the company is currently with many well-known domestic enterprises and multinational corporations has a broad and close business cooperation, the company is actively expanding production capacity, continuous innovation, improve the level of process and technology, take the road to quality, better service provided to our customers.

Workshop: