Basic Info.

Al2O3

45.3%

MGO2

0.22%

Application

Refractory Furnace Lining Insulation Materials

Transport Package

Woven Bag

Specification

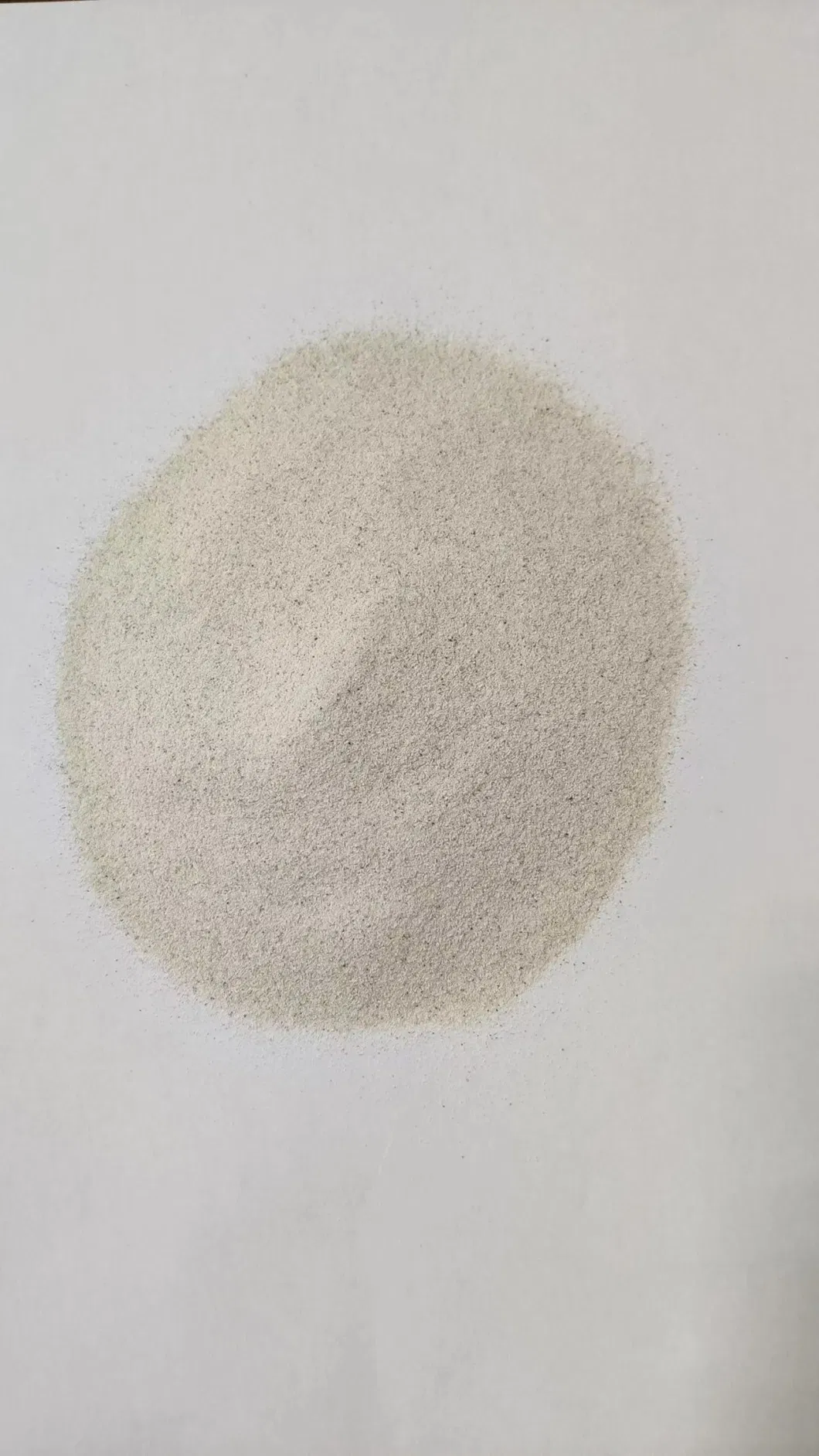

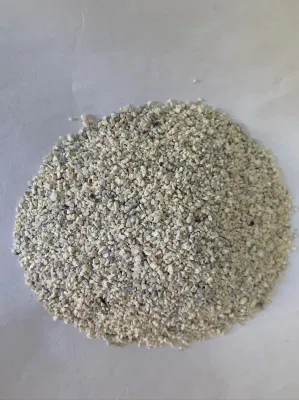

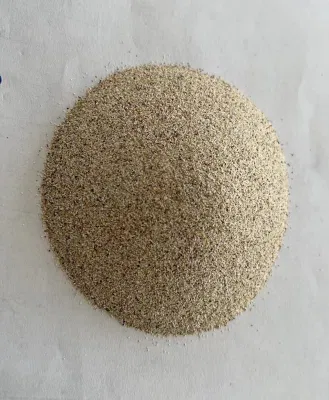

16-30MESH,30-60MESH,60-80MESH,80-120, 200, 325MESH

Trademark

HEBO

Origin

China

HS Code

25087000

Product Description

Product Description

precision casting process. The characteristics are small expansion coefficient, high hardness,

Strong resistance to chemical corrosion,high refractoriness, good thermal and chemical

stability,resistance to extremely cold / heat, etc., while product molding shell and pouring

castings it's easy shelling,no deformation,not reduce scale,good finish, high yield.The

product can be used for complex casting of carbon steel, stainless steel, heat-resistant steel.

1.Grain shape of the foundry sand is close to the true round with smooth surface,

good fluidity and fillibility, easy to be filled ,it can get good formability and strength of

mold.

2.Foundry sand has a good collapsibility, easy to carry out the sand cleaning operation.

The usage amount of binder is more less than other types of sand.

3.Compounding moulding sand with foundry sand, casting will not have defects of

expansion cause it has low thermal expansion rate.

4.Producing castings with foundry sand will have high accuracy ,less fracture and

surface defects, what's more it can also improve the yield of casting.

5.Foundry sand has good crushing resistance and high strength, it's rarely broken

even if reuse.

6.The foundry sand with good reproducibility can reduce dust pollution in the

production process and industrial waste emissions,is conducive to environmental

protection.

7.Foundry sand has a good fire resistance,refractoriness ≥1790 ºC which makes it can cast various metals and alloys.

| Item | Chemical Compostion | % |

| 1 | Al2O3 | 45.3 |

| 2 | SiO2 | 51.26 |

| 3 | Fe2O3 | 1.07 |

| 4 | K2O | 0.10 |

| Na2O | 0.12 | |

| 5 | CaO | 0.56 |

| MgO2 | 0.22 | |

| 6 | TiO2 | 0.77 |

| 7 | Flameresistant ºC≥ | 1770 |

| 8 | LOI | 0.29 |