Basic Info.

Model NO.

Q69

Fuel

Electric

Type

Roller Conveyor Shot Blasting Machine

Cleanliness

High Cleanliness

Automation

Automatic

Certification

CE

Feature

Critical Cleaning / Residue Free, Rust / Corrosion

Condition

New

Customized

Customized

Shot Blasting Machine Warranty

One Year

Industrial Experience

Over 20 Years Professional Design Experience

Cleaning Process

Steel Shot, Sand Grit and Other Abrasive

Shot Blasting Machine Material

High Chrome Castings, Zgmn13, Mn65, Q235A, etc

After-Sales Service Provided

Available to Service Machinery Overseas

Exported Countries

USA, UK, Russia, Australia, Mexico, Brasil, etc

Blast Wheel

High Chromium Wear Resistant

Dust Collector

Cartridge Filters, Fireproof and Antistatic

Machine Type

Roller Conveyor Shot Blasting Machine

Packaging Detail

Pallet, Foam and Plastic Film/Customized

Transport Package

Pallet, Foam and Plastic Film/Customized

Specification

CE, Sa 2.5

Trademark

Puhua

Origin

Shandong China(Mainland)

HS Code

84243000

Production Capacity

200 Sets Per Year

Packaging & Delivery

Package Size

700.00cm * 400.00cm * 300.00cm

Package Gross Weight

9000.000kg

Product Description

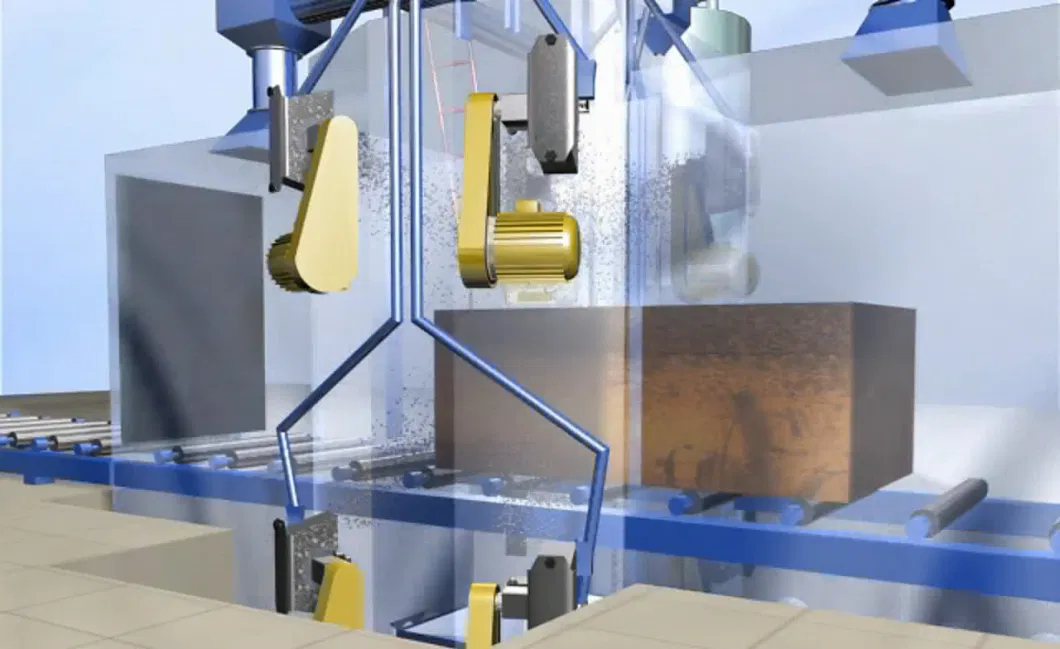

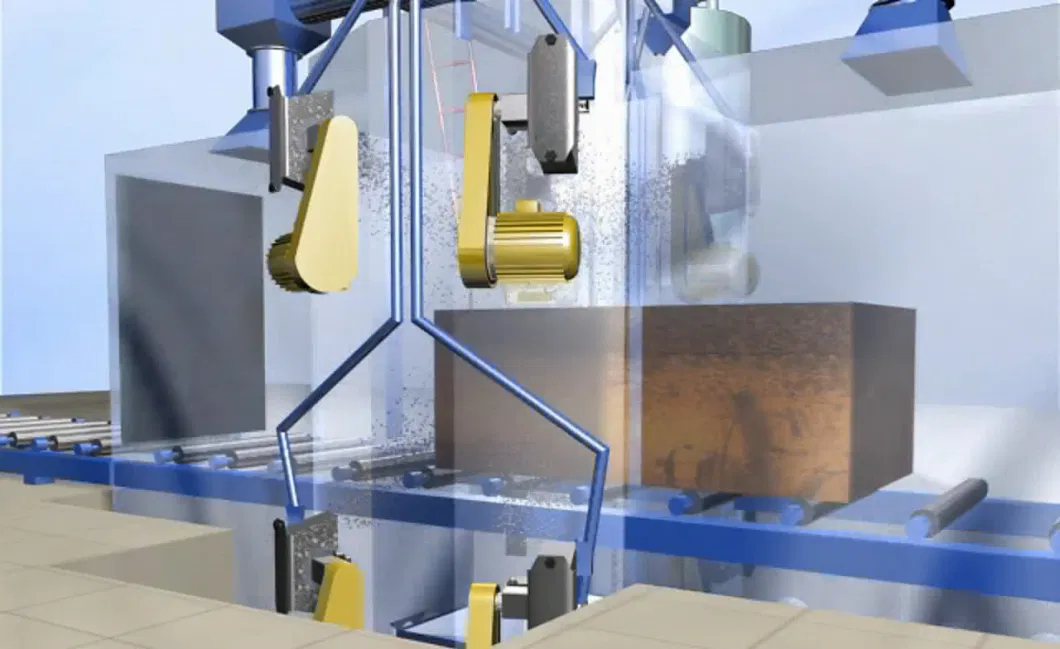

H Beam Metal and steel plate Roller conveyor shot blasting machine

Q69 steel plate,section shot blast clean-up machine is mainly composed of such stage as preheating,shot blast cleaning,painting

and stove,ect. It is suitable for the surface derusting&painting craft for steel plates and sections in such industries as

shipmaking, automobile making,locomtive vehicle,bridge and machinery .

The series belongs to roller-type blast cleaning machine, mainly used for buildings, bridges and other industries with large I-beam,H-beam steel structure such as size pieces of high stress and the elimination of cleaning the surface rust.

Product Paramenters

Product Features

Customizable

Various non-standard steel pretreatment equipment can be designed and manufactured according to the

steel size you provide.

Long service life,manual or automatic control

Rollers in the blasting cabinet are protected by special alloy jacket with lifetime over 4,000 hours.

high wear resistant performance easy to replace

In the blasting chamber, the wall is protected by SPMn13 material liner and 65Mn protective liner, easy tear open outfit replacement.

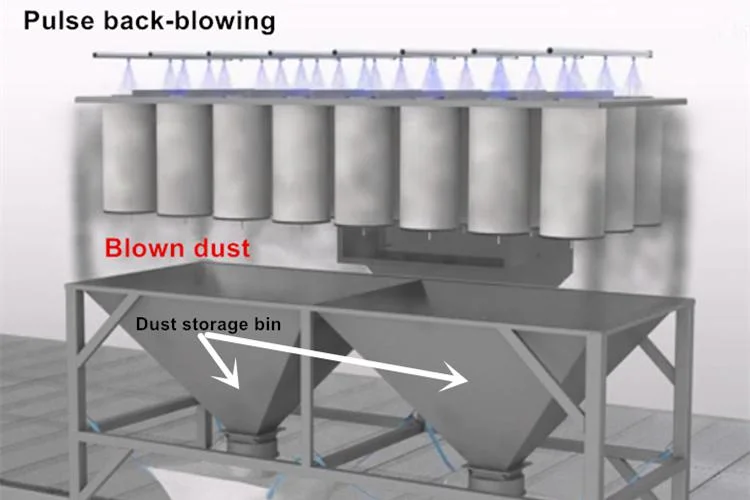

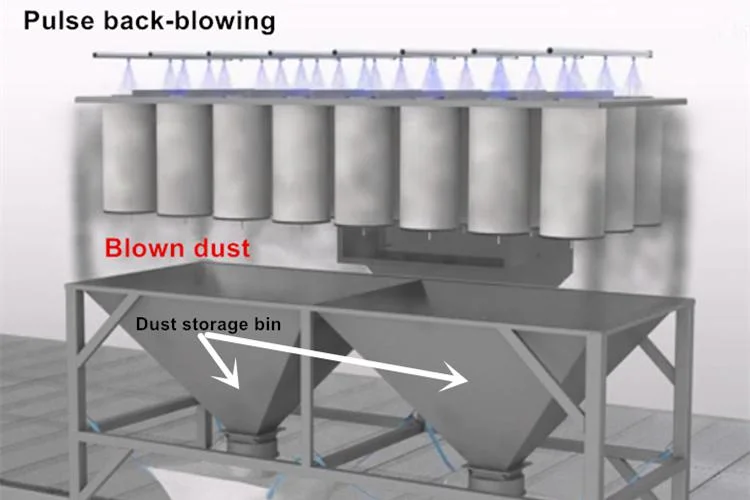

High dust removal effect,low pollution

The dust removal system consists of ducting system and filter cartridge dust collector. The emission standard can be lower 80 g/m3. The fan power is 30 kw, ventilation quantity is 26000 m3/h.

FAQ

Q69 steel plate,section shot blast clean-up machine is mainly composed of such stage as preheating,shot blast cleaning,painting

and stove,ect. It is suitable for the surface derusting&painting craft for steel plates and sections in such industries as

shipmaking, automobile making,locomtive vehicle,bridge and machinery .

The series belongs to roller-type blast cleaning machine, mainly used for buildings, bridges and other industries with large I-beam,H-beam steel structure such as size pieces of high stress and the elimination of cleaning the surface rust.

Product Paramenters

| Type | Q69(customizable) |

| The effective cleaning width(mm) | 800-4000 |

| The room feed-in size(mm) | 1000*400---4200*400 |

| The length of cleaning workpiece(mm) | 1200-12000 |

| The speed of wheel conveyer(m/min) | 0.5-4 |

| The thicksness of cleaning steelsheet(mm) | 3-100---4.4-100 |

| The section steel specification(mm) | 800*300---4000*300 |

| The quantity of shot blasting(kg/min) | 4*180---8*360 |

| The first enclosed quantity(kg) | 4000---11000 |

| Roll brush adjusting height(mm) | 200---900 |

| Airness capacity(m³/h) | 22000---38000 |

| Exterior size(mm) | 25014*4500*9015 |

| Total power(except for dust cleaning)(kw) | 90---293.6 |

Product Features

Customizable

Various non-standard steel pretreatment equipment can be designed and manufactured according to the

steel size you provide.

Long service life,manual or automatic control

Rollers in the blasting cabinet are protected by special alloy jacket with lifetime over 4,000 hours.

high wear resistant performance easy to replace

In the blasting chamber, the wall is protected by SPMn13 material liner and 65Mn protective liner, easy tear open outfit replacement.

High dust removal effect,low pollution

The dust removal system consists of ducting system and filter cartridge dust collector. The emission standard can be lower 80 g/m3. The fan power is 30 kw, ventilation quantity is 26000 m3/h.

FAQ

| 1 | Q: How many days to produce this machine? |

| A: Some standard machines in stock, can be delivered right away after your deposit. Customized specially designed machine according to your specific requirement. From engineer designing to production completion, it needs about 30 to 50 days. | |

| 2 | Q: What does your factory do regarding quality control? |

| A: We pay much attention to quality control from the very beginning to the end. Each machine is assembled and carefully tested before shipment. | |

| 3 | Q: What's your machine quality guarantee? |

| A: Quality guarantee time is one year. We choose world famous brand components to keep our machine in perfect working condition. | |

| 4 | Q: Could you give installation and commissioning overseas? How long will it take? |

| A: Yes, we supply overseas service, customers shall pay for the engineers flight tickets and local transport, hotel, food. Small machines usually takes 5 days, while big machines usually takes about 20 days even one or two months. | |

| 5 | Q: How can I trust you to deliver the right machine as I ordered? |

| A: We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is innovation, quality, integrity and efficiency. Puhua is ALIBABA's Golden supplier with BV assessment. You can check with ALIBABA. We have never got complaint from our customers. |