Basic Info.

Model NO.

OEM Carbon Steel Sand Casting

Surface Treatment

Spray-Paint

Surface Roughness

Ra0.2

Standard

ASME

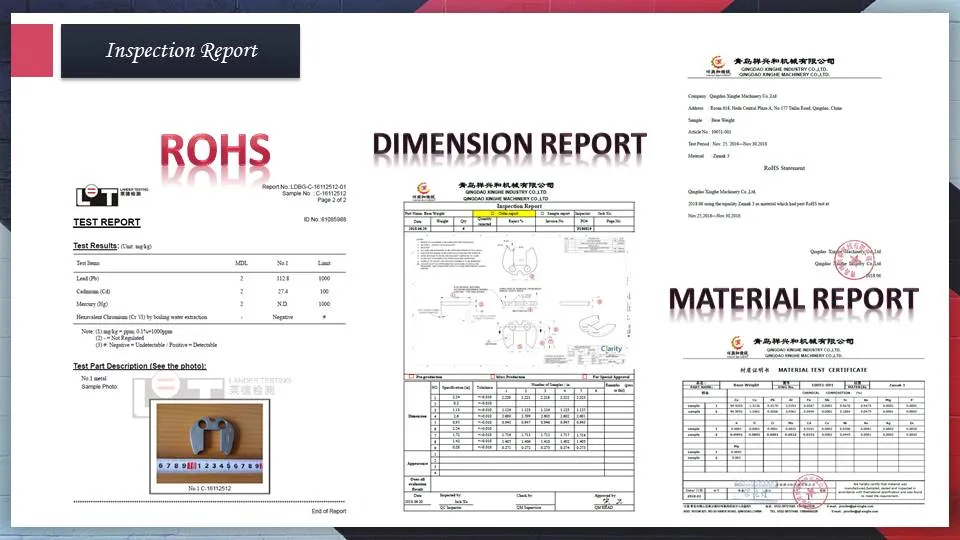

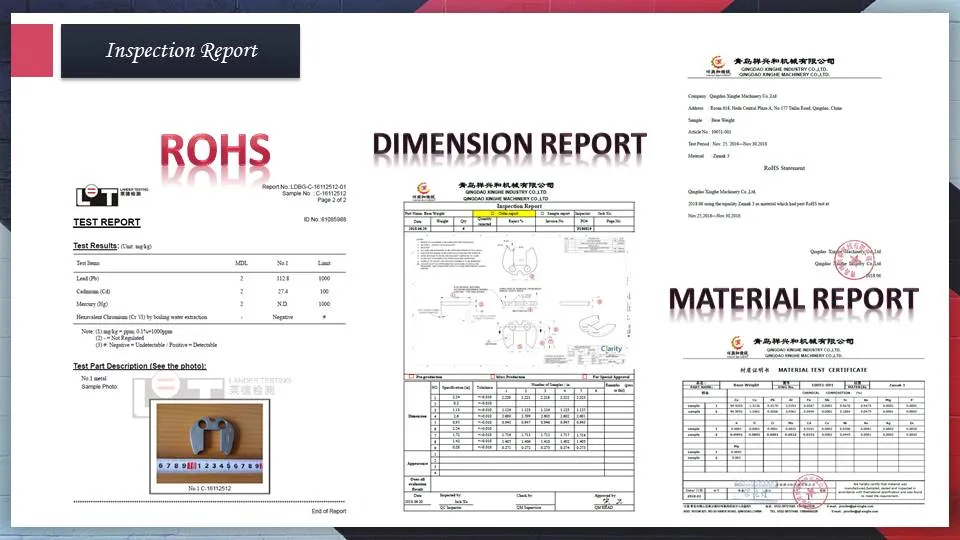

Certification

CE, RoHS, ISO 9001:2000, ISO 9001:2008

Name

Custom High Quanity Carbon Steel Sand Casting

Technology

Sand Casting/Precision Casting/Die Casting

Brand Name

Xh

Surface

Polishing, Power Coated, etc.

Mainly Standard

ISO 9001:2008, AISI, CE, Ieo, SGS

Other Machining

Drilling, Tapping, Milling, Grinding, etc.

Other Material

Gray Iron, Ductile Iron, Aluminum, etc.

Price

Factory Price

Packaging

as Per Your Request

Delivery Time

30 Days After Payment

Transport Package

According to Customers′ Requirement

Specification

As drawings

Trademark

XH

Origin

Qingdao, China

HS Code

7325101000

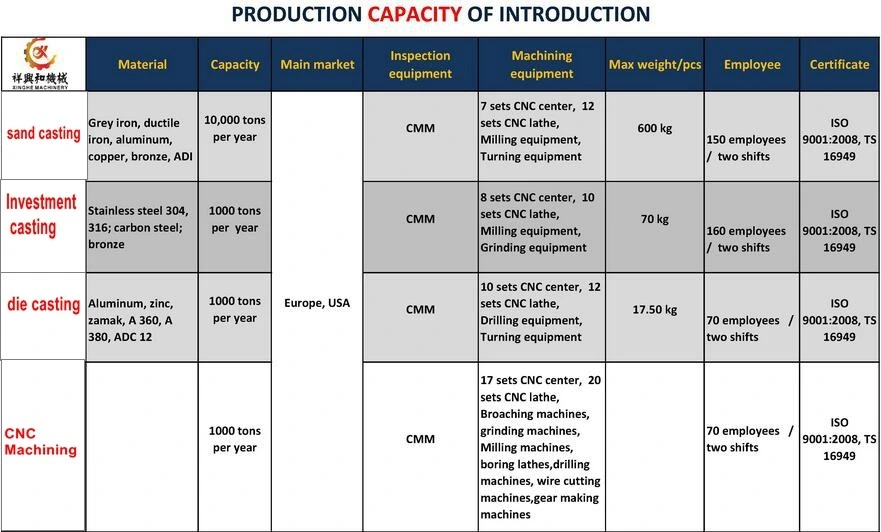

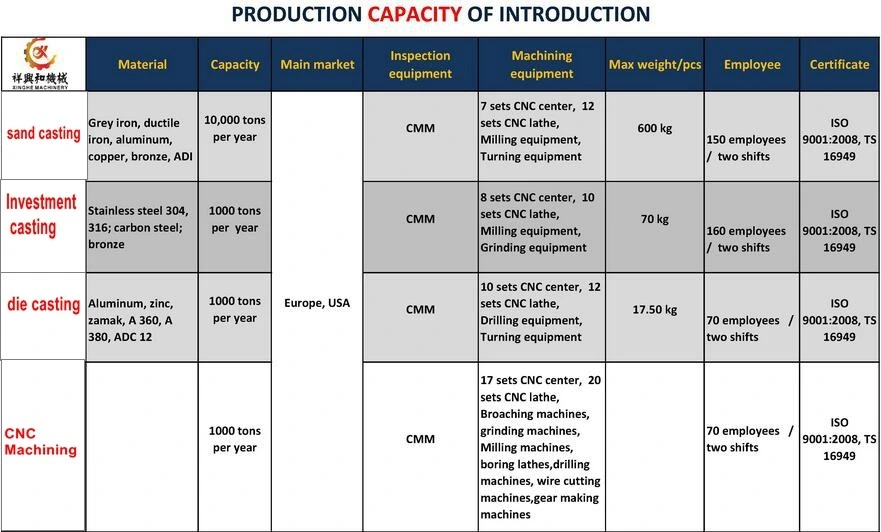

Production Capacity

200tons to 500tons Per Month

Product Description

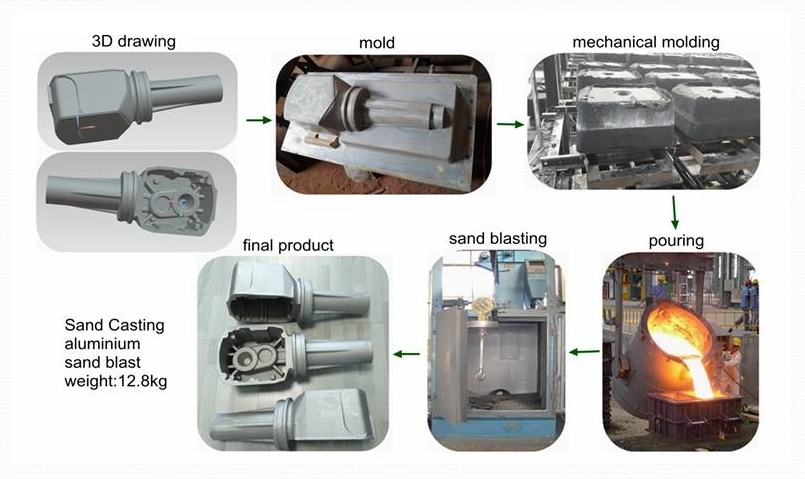

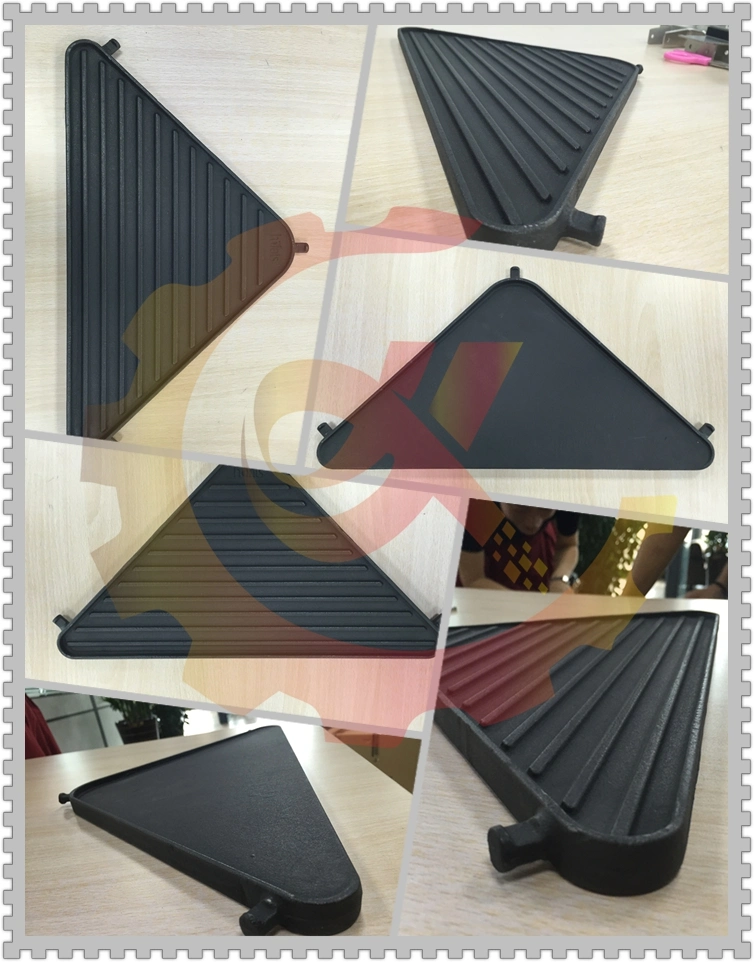

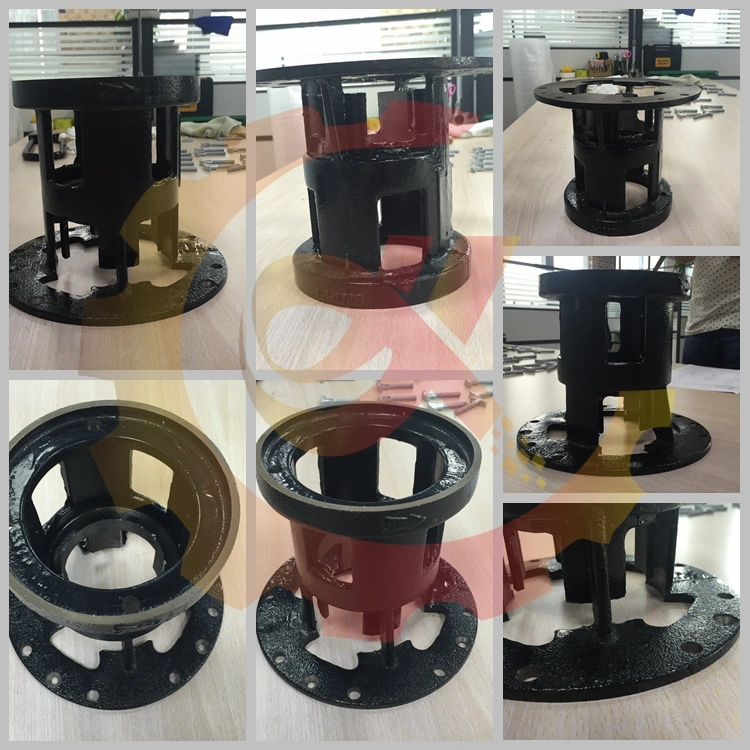

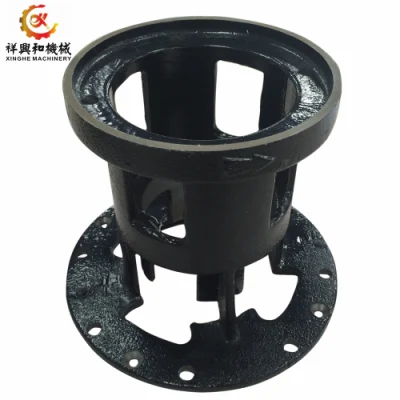

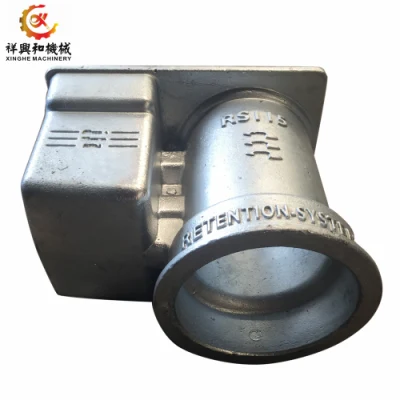

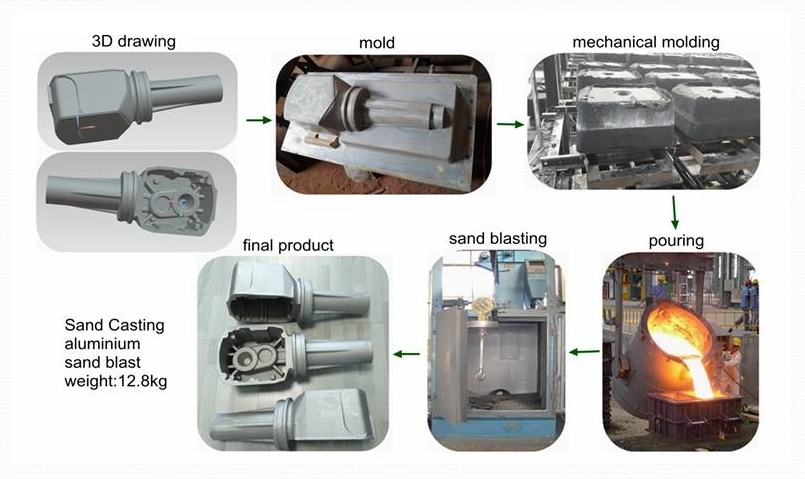

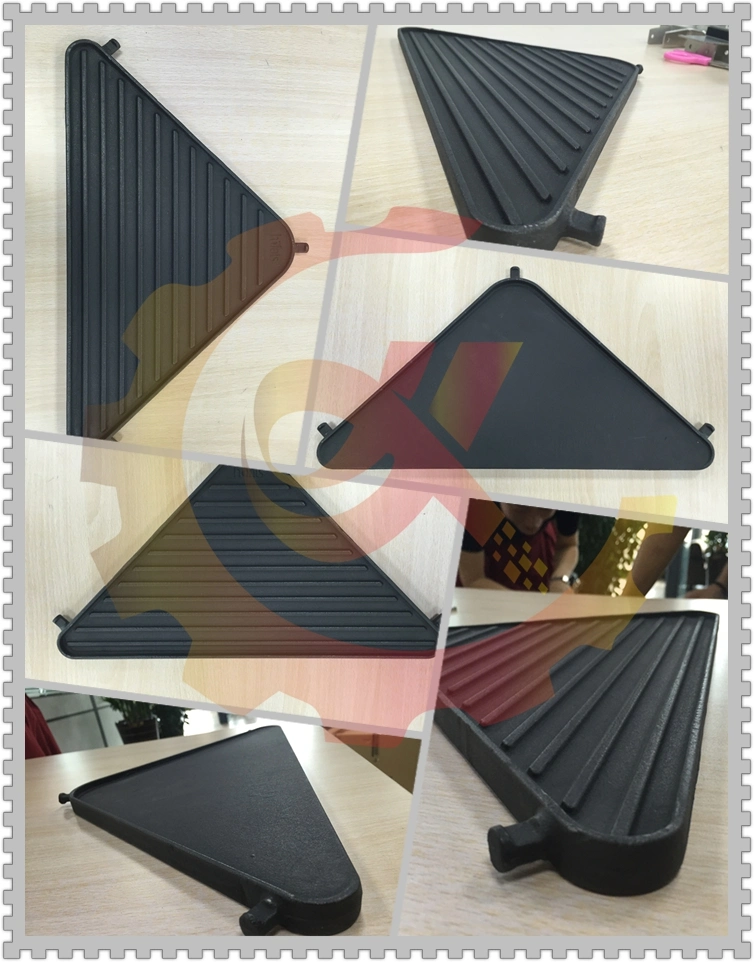

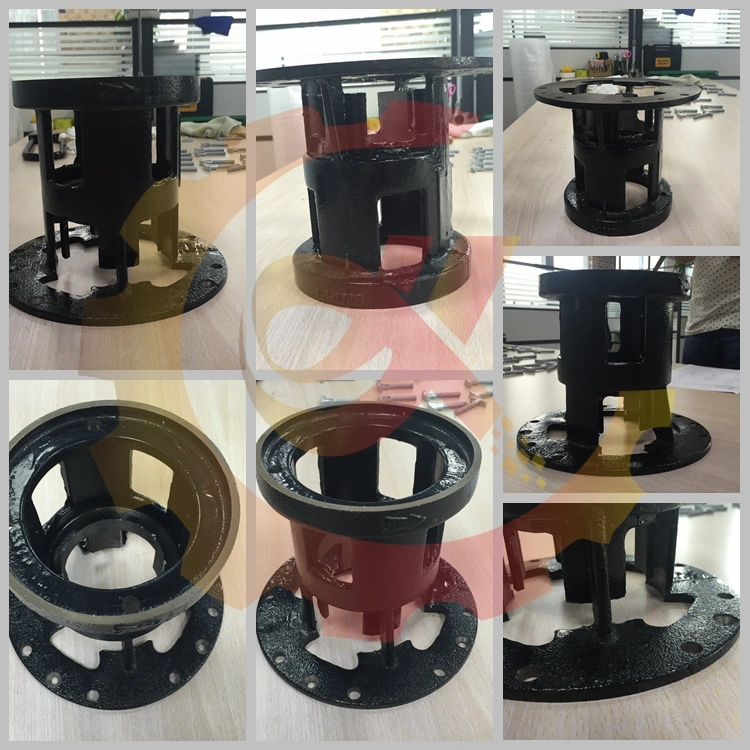

Custom High Quanity Carbon Steel Sand Casting

Material: Grey Iron, Ductile Iron, Aluminum, etc.

Surface treatment: Polishing, Power coated, Painting, Heat treatment, etc.

Made according to customers' drawings, specification or samples

Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF, Solidwork, etc.

Casting capability: 200-500 tons / per month.

Casting techniques: Sand casting, precision casting, die casting.

Machining: Turning, cutting, milling, grinding and drilling.

Packing: Carton box then on wooden crate or according your request.

OUR ADVANTAGES:

1) Experience in casting for more than 10 years.

2) Stable business relationship with customers all over the world.

3) More than 500 professional and hard working employees.

4) Incoming material inspection

5) Inspection of work-in-progress

6) Finished product inspection

7) Random warehouse inspections

8) On time delivery.

Our purpose: To be your reliable friend.

Looking forward to your message.

Hope we can build good cooperation with you.

Material: Grey Iron, Ductile Iron, Aluminum, etc.

Surface treatment: Polishing, Power coated, Painting, Heat treatment, etc.

Made according to customers' drawings, specification or samples

Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF, Solidwork, etc.

Casting capability: 200-500 tons / per month.

Casting techniques: Sand casting, precision casting, die casting.

Machining: Turning, cutting, milling, grinding and drilling.

Packing: Carton box then on wooden crate or according your request.

OUR ADVANTAGES:

1) Experience in casting for more than 10 years.

2) Stable business relationship with customers all over the world.

3) More than 500 professional and hard working employees.

4) Incoming material inspection

5) Inspection of work-in-progress

6) Finished product inspection

7) Random warehouse inspections

8) On time delivery.

Our purpose: To be your reliable friend.

Looking forward to your message.

Hope we can build good cooperation with you.

| PROCESS | MATERIAL | STANDARD | |

| SAND CASTING | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stainless Steel, Carbon, Steel, Aluminum, Brass, Bronze | ASTM BS JIS DIN etc |

| Furan Resin Sand | |||

| Cold Harden Resin Sand | |||

| INVESTMENT CASTING | Sodium Silicone (Water glass) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum | |

| Silica Sol | |||

| FORGING | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum | |

| Die Forging | |||

| Roll Forging | |||

| STAMPING MACHINING | STAMPING MACHINING | All metal material | |