Basic Info.

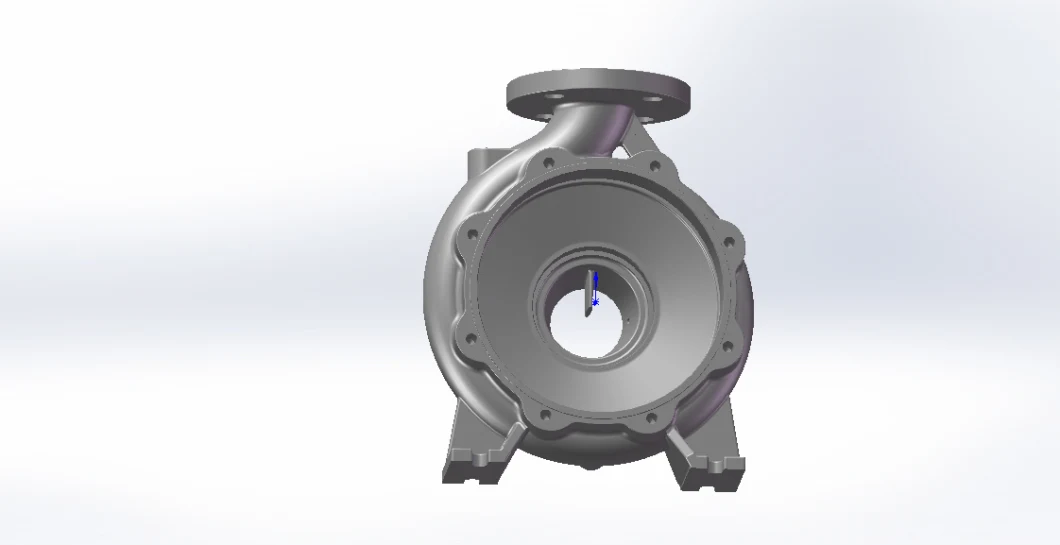

Product Description

Raw Material | Ductile iron, ADI, grey iron, carbon steel, alloy steel, aluminium and stainless steel |

Casting Process | Green sand casting, resin sand casting, lost wax steel casting and silicon sol casting |

Tolerance | ISO8062 CT5-CT9 |

Roughness | Ra3.2-Ra12.5 |

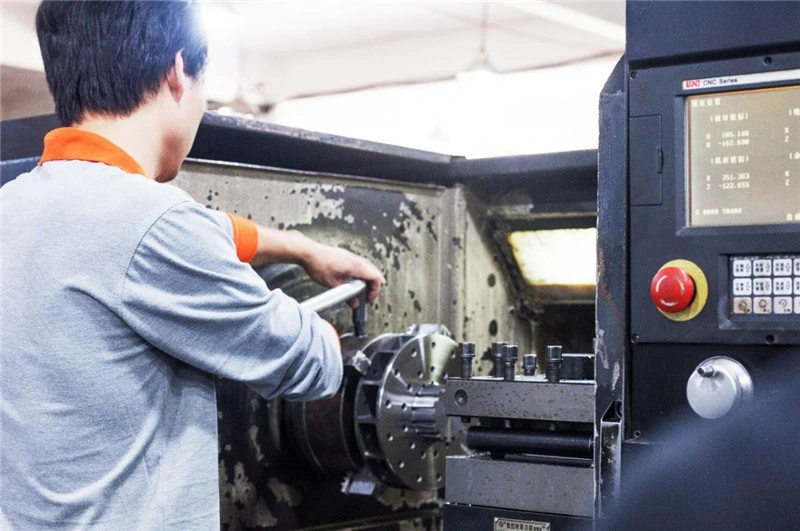

CNC Machines | 12 sets of MC and 20 sets of CNC lathes |

Machining Tolerance | 0.01mm |

Quality Control | The first sample checking, process monitoring and final quality checking |

Finish | Phosphating, primer painting, anti-rust oil, powder coating, galvanized zinc coating, electro polishing and shot blasting |

| |

Service | OEM/ODM offered |

Sand Casting Pattern Workshop

With our automatic sand molding line, it great improve the iron casting quality ,save the manufacturing cost, and help the lead time.

We can supply very competitive price with good quality, fast lead time, efficient quotation, feel free to email us the RFQ for sand casting parts.

We have two factory shops for sand casting products,cast from the material of cast iron, ductile iron casting, aluminum, brass. We have both towering furnace for big melting volume and intermediate frequency furnaces for less melting volume. The annual output capability is more than 1000 tons. Our mainly sand casting parts is: for the diesel oil vehicles of engine body and impeller, various water pump body and housing, for the food industry machine, such as tomato mill machine parts of body and Spiral, meat mincer machine parts of body,Spiral and ring. We also can cast the big body for grinding or lathe machine.

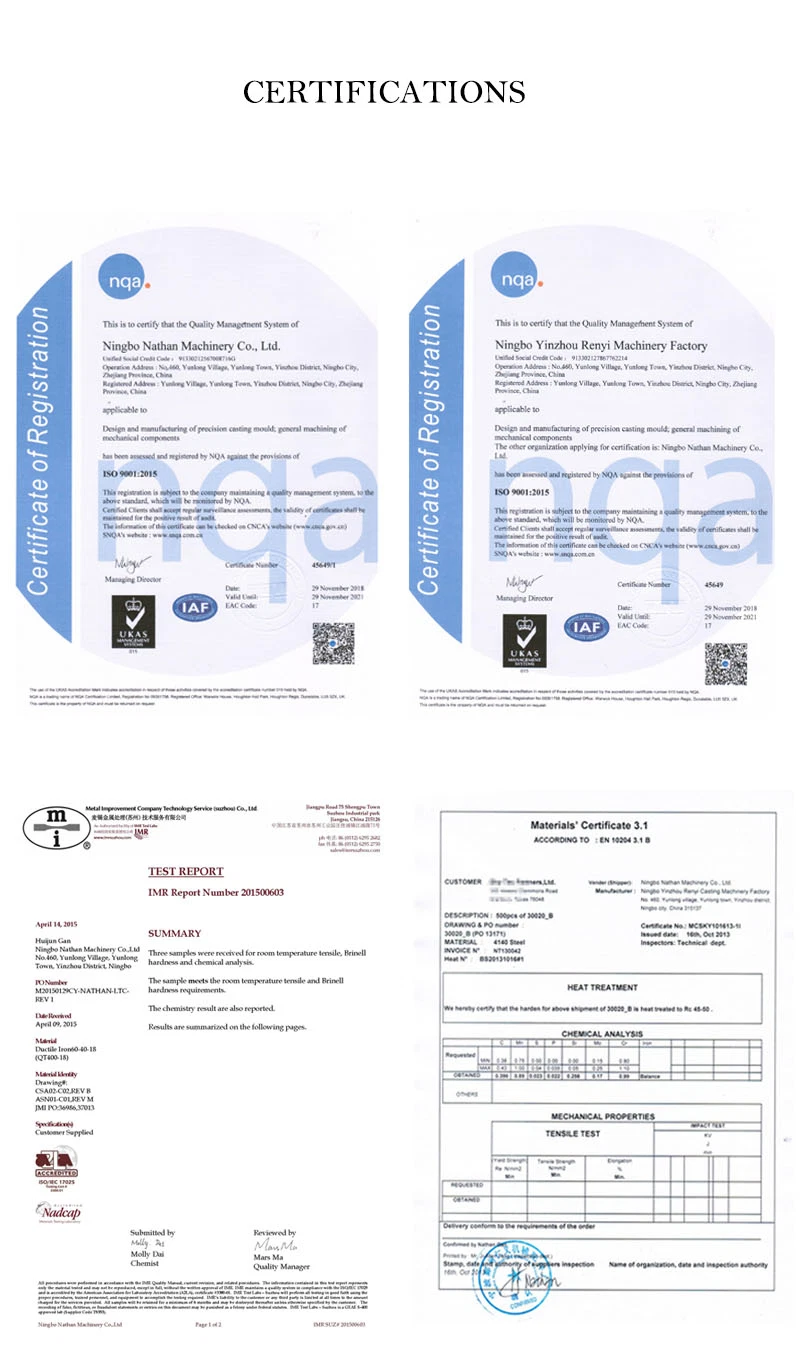

We can supply official Material Chemical report, Tenstile testing report.

Certificates

FAQ

1.What do you need to provide a quote?

Please kindly send us the drawing of your product. Details below should be included,

A.Materials B. Surface Finish C. Tolerance D. Quantity

(Please be noted that these are essential for our quoting. We couldn't quote the specific

price without any of them.).

2.When can I get the price?

Our professional sales team will feedback your RFQ within 12hours, and give you the Quotation within 48hours max. if the drawing and specification is all in details.

3.How can I get the sample to check your quality?

After price confirmation, you can require for samples to check our product's quality. If you just need a blank sample to check the manufacturing quality, we will provide you sample after the sample order confirmed.

4.What's the lead time for Mould and samples ?

For normal project, we can complete Mould and supply the 1st article sample within 30 to 40days.

For urgently project, we can complete the Mould and Sample within 20days max.

5.What's the payment terms for Order ?

For Mould/tooling and sample : 50% deposit pay by Order, rest 50% pay after sample approval.

For production Order for new Customers : we request 30% down payment, rest 70% pay by copy of Original B/L copy. For long lasting regular customer, we can give better payment terms, such as 100% pay after delivery or by B/L copy.