- Overview

- Detailed Photos

- Product Parameters

- Company Profile

- Exhibition Photos

- Customers Photos

- Packaging & Shipping

Basic Info.

Product Description

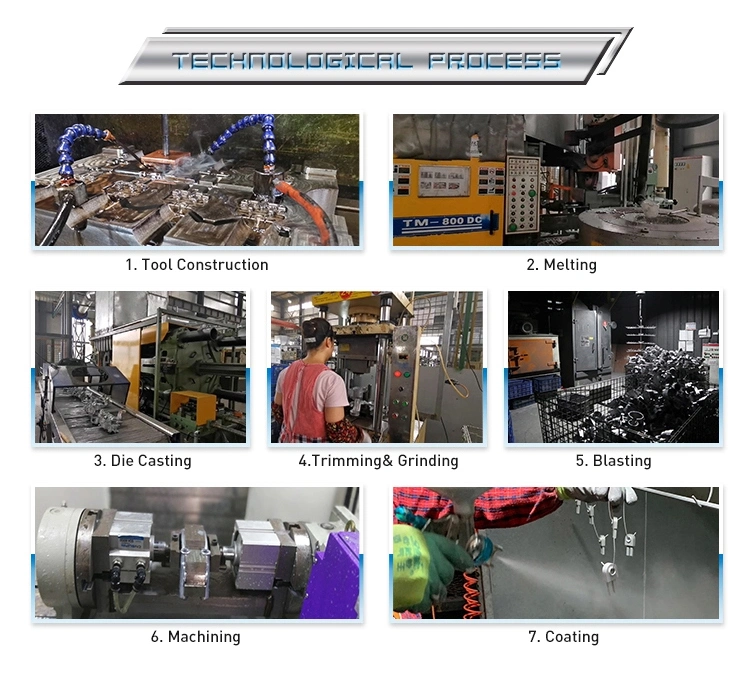

| Process | Aluminum Die casting, Zinc Alloy die casting,CNC machining,Surface Treatment |

| Production Equipment | Cold chamber die casting machine:280T/360T/400T/500T/800T/1250T. CNC Centers. CNC Lathes. |

| Inspection Equipment | CMM,X-RAY |

| Material | Aluminum Alloy: A319, A356, A360, A369, A380, A383, A384, A413, A535, 44300, 44300, 46000, AlSi9CU3, ADC12, ZL102, ZL104, ZL108, YL112 Zinc Alloy: Zamak 2,3,5,7 ect. |

| Surface | Trimming, Deburring,Polishing, Sand blasting,Vibration, Powder coating, Anodizing, Chrome |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD |

| Products Application | Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect. |

Ningbo Beilun HongXiang Casting Co,Ltd is a Professional manufacturer of die casting products and die casting mold.We are located in ningbo,zhejiang,china.We can produce all kinds of aluminum&zinc nonstandard products according to your' designs. We assists manufacturers who require aluminum&zinc die cast parts. These industries include: Automotive,Appliance, machine, Communications, Small engines, Garden, Housing, Transportation, Lighting, white goods.

There are some facts about us company;

> 280T/360T/400T/500T/800T/1250T die casting machines

> Three Shifts, Shorten Production Time

> ISO9001 Certification

Our customers use us because:

> Fast Die casting Part Production and Delivery

> Reasonable price

> We can in many cases Add value to our customer's products. Added value would be secondary operations such as machining, powder coating, sand blasting, vibration,

painting, Polishing, assembly and packaging.

> We make new mold by ourselves, we have 25 years' experience of mold

making. So we can fix mold quickly once we meet problems in production.

> Good transportation, 15 mins by truck to Ningbo port.

> We use CMM and X-Ray to ensure our products' quality.

> we have wide die casting tone range so we can available different sizes products

Factory Tour

It mainly depends on parts dimensions, customers requirements.

FAQ

1. Are you factory or trading company

A:We are factory and we have export rights.

2.What is the lead time for mold and samples?

A.We can finish it and send you samples after 30-70days, different molds lead time mainly becuase of mold dimension and mold complexity

3. Shipping

A. For samples,FEDEX, DHL, UPS, TNT etc can be provided.

B. For massive order,we can arrange shipment by sea or by air according to your requirement

4. What is the payment for the order?

A:For Mould/tooling and sample : 50% deposit pay by Order, rest 50% pay after sample approval.

For production Order for new Customers : we request 30% down payment, rest 70% pay by copy of Original B/L copy.