- Overview

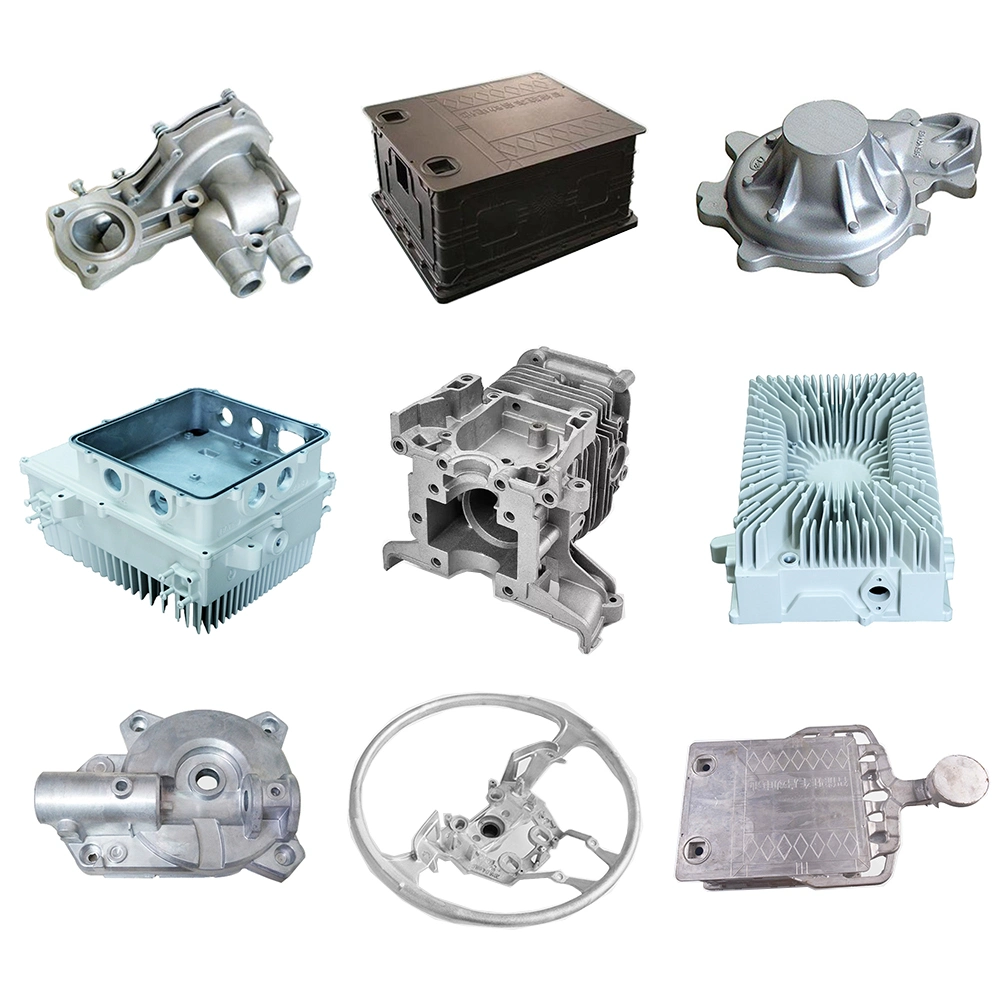

- Product Description

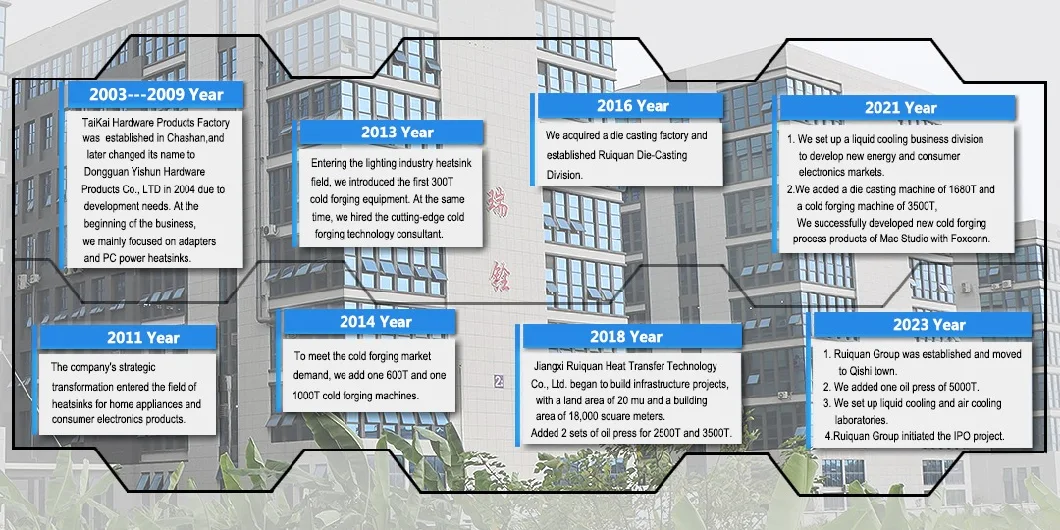

- Company Profile

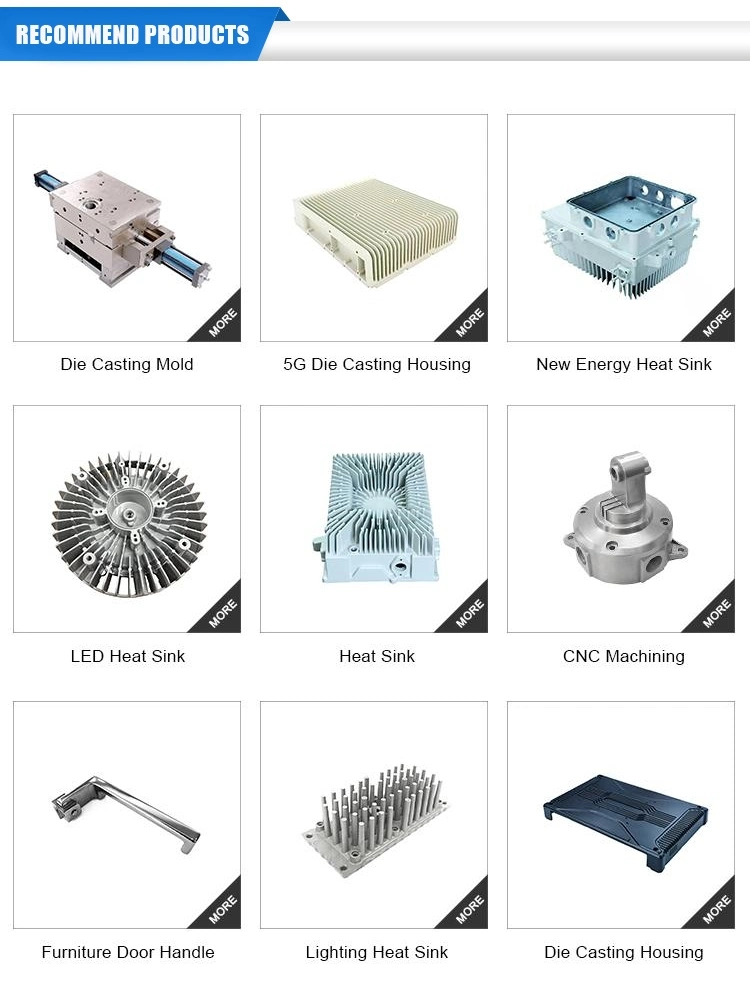

- Recommend Products

- Exhibition Show

- Customer Visit

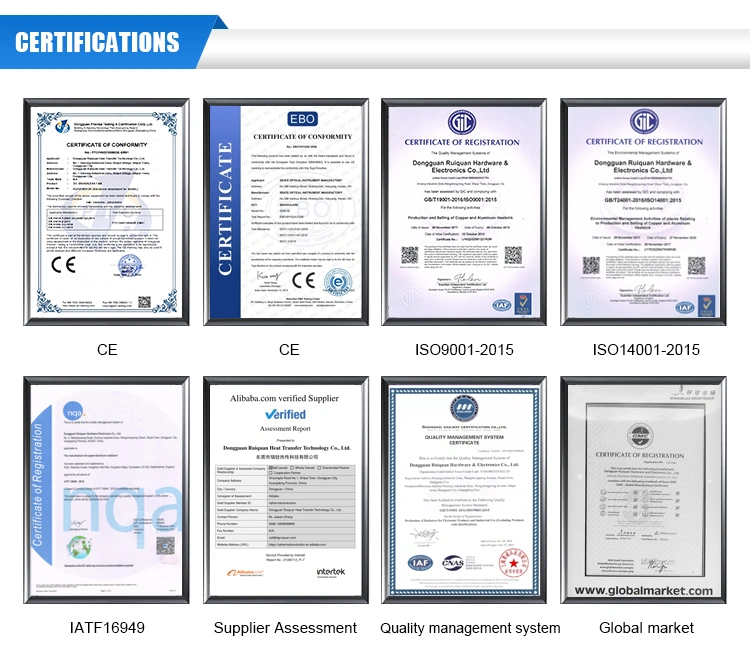

- Certifications

- Why Choose Us

- FAQ

Basic Info.

Model NO.

RQ-DC00631

Machining

CNC Machining

Material

Aluminum Alloy

Surface Preparation

Spray Coating

Pressure Chamber Structure

Horizontal

Tolerance Grade

5

Casting Surface Quality Level

1

Certification

CE, RoHS, ISO 9001:2000, ISO 9001:2008, IATF16949

Warranty

2years

Product Name

Aluminum Heat Sink

Size

Customized Size

Custom

Non-Brands

Drawing Format

Pdf, Dxf, Dwg, Step, Igs, X-T, etc.

Certificates

So9001:2015 IATF16949, Rosh

Surface Treatment

Paint, Powder Spraying, Electroplating, etc

Materials

Aluminum Alloy ADC12, Zinc Alloy, etc

Processing

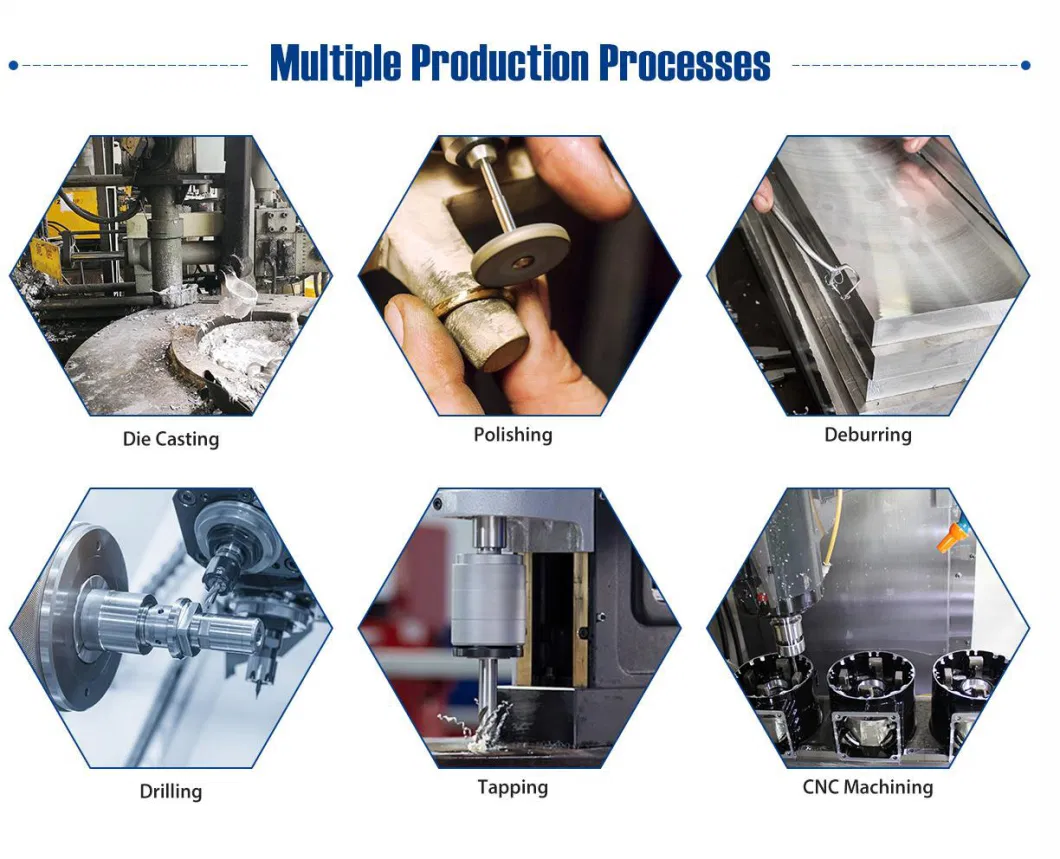

Die Casting, CNC Machining, Drilling, etc

Aftersale Service

The Best

MOQ

Small MOQ

Delievery

Fast Delivery

Inspection

Full Inspection Before Shipping

Mold

Designing and Free Dfm

Production Line

10

Transport Package

Customer Requirements

Specification

Customer Requirements

Trademark

OEM

Origin

Made in China

HS Code

7616999000

Production Capacity

500000PCS/Month

Packaging & Delivery

Package Size

15.00cm * 8.00cm * 5.00cm

Package Gross Weight

1.000kg

Product Description

| Product Name | Electrical car part Aluminum Metal Auto Parts Die Casting in ADC12 A380 |

| Materials | Aluminum alloy: ADC12, A360, A380 etc. Zinc alloy: zamak 3, zamak 5 etc. CNC Sample: AL6061 |

| Production Processing | DFM report-Design confirm-Tooling design-Tooling making- Tooling testing-Die casting- Degating- Polishing/grinding- CNC machining-tapping/threading- Deburring- Inspecting- Surface treatment- Inspecting- Packing |

| Surface Treatment | Polishing, anodizing, powder coating, passivating, painting, plating, sand blasting, e-coating for surface; Laser carving, screen printing, pad printing for logo and others as your requested |

| Tolerance | +/-0.05mm~ +/-0.2mm |

| Service | OEM service, R&D team supported |

| Drawing Format | 2D(DXF, DWG,CAD), 3D(IGS, STEP, SLD, X_T) etc. |

| Certificate | ISO9001:2016, ISO14001:2016; IATF16949, ROSH,QC080000 |

| Main Production Equipment | Cold chamber die casting machine (from 280T~1680T), hot chamber die casting machine, CNC machine, CNC lathe, punching machine, polishing machine, grinding machine, drilling machine, tapping machine, multi-axis tapping machine, passivating, powder coating, sand blasting machine, printing, laser carving etc. |

| Main Testing Equipment | Calipers / 2.5 measuring instrument / CMM / Height gauge / Go-no go gauge / Roughness measurement / RoHs testing / Salt Spray testing machine etc. |

| Application | Led light housing & Led Heatsink Auto motorcycle & bicycle parts Automobile Industries Mechanical parts Furniture accessories New Energy Industries Industrial equipment spare parts Medical equipment industries other all kinds of electronics products |

| MOQ | Small order is acceptable, Mass product depend on the detail. |

| Sample lead time | 35-45days for sample including tooling time. |

| Product lead time | 35-45days for sample including tooling time. |

| Product lead time | normally about 30 days for mass production, also depend on your quantity. |

| Payment terms | T/T, alibaba trade assurance. |

| Delivery Method | By Express Courier, such as DHL, Fedex,UPS, TNT, EMS etc.;by air, by Land or by Sea; |

Dongguan Ruiquan Hardware Electronics Co., Ltd

RuiQuan group own two factories, one is located in Dongguan city, Guangdong province and one is located in Taihe city, Jiangxi province. Total covers 40,000 square meters with more than 500 employees.

Dongguan Ruiquan Hardware Electronics Co., Ltd is the headquarter with more than 250 employees.

RuiQuan group has a complete technology and production range, including aluminum die casting, zinc die casting, cold forging heat sink, aluminum extrusion heat sink, cooling fan, heat pipe heat sink, skiving heat sink, precision CNC machining and so on.

RuiQuan mainly provide OEM service. We have a professional R&D team of more than 15 people with more than 30 years' experience.They are good at optimizing customers' products and cost.

RuiQuan has 12 aluminum die casting machines from 160T to 1680T and more than 50 sets CNC machines. Our output production capacity is around 800,000pcs per month.

We are 100% direct factory. Ruiquan have 3 factories, the headquarters is located in Dongguan city, Guangdong province.Welcome to visit our factory.

Q2. What kind of production service do you provide?

All kinds of heat sink including aluminum extrusion heat sink, cold forging heat sink, precision mold making,aluminum/zinc die casting parts, heat pipe and cooling fans.

Q3.What if I want existing model?

We have tens of thousands of existing model to provide customers, and detail description with drawings.If there are no identical products, we will recommend similar products for you.

Q4. How about the lead time?

Mold and sample: 3-5 weeks

Mass production: 2-4 weeks

Depends on processing and quantity.

We can make a special arrangement if your order is urgent.

Q5. How about your quality?

♦We have got ISO9001:2015 and IATF16949 certificates.

♦Make the operation instruction once the sample is approved.

♦100% inspect the products before shipment.

♦We are apple's supplier and they are satified with us.

Q6. How long should we take for a quotation?

After receiving detailed information(your 2D/3D/CAD drawings or samples,Material, Finish, and Quantity),we will quote you within 2 days.

Q7. What is your payment term?

Mold: 50%-100%prepaid.

Goods: 30% prepaid, balance T/T before shipment.

Q8. How soon can I get samples and how much the fee?

Depending on your specific project, it usually takes 15 to 25 days. the fee depends on the product drawing,and the fee will be returned to your bulk order.

Q9. How to enjoy the OEM services?

Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you,after your agreement, we produce for you.

Q10.Will my drawing safe after you get it?

Yes, we can sign the NDA before got your drawing.