Basic Info.

Model NO.

AS029

Surface Treatment

Sand Blast

Surface Roughness

Ra0.2

Standard

AISI

Certification

CE, RoHS, ISO 9001:2008

Transport Package

According to Customer

Specification

According to customer

Trademark

PeopleMech

Origin

China

Production Capacity

10000 Tons/Year

Product Description

| Specification | OEM customized resin coated sand casting of nodular cast iron , ductile iron sand casting, coated sand steel casting factory | |||

| Production Line | Automatic coated sand core machine | |||

| Material | Cast iron: GG20, GG25, GG30 Ductile iron: GGG40, GGG45, GGG50, GGG55, GGG60, GGG70 Carbon steel: C25, C35, C45, 42CrMo... | |||

| Finish | Shot-blasted, Anti-rust oil, powder coating, painting... | |||

| Standard | ASTM, AISI, DIN | |||

| Drawing Format | 2D Drawing: .dxf/ .dwg / .pdf /.jpg / .tif /.bmp 3D Drawing: .step / .stp /.igs | |||

1. Introduction

Coated sand casting has low environmental pollution and low production costs. It uses automated production lines for operation, improves production power, reduces labor intensity, and shortens labor time.

Modifying the appearance quality of the rough casting, reducing cutting allowance, achieving high production rate and stable quality.Trial use for small and medium-sized products weighing between 1-100kg,

Due to the fast cooling speed during the casting process of coated sand molding, the graphite shape of the casting has been greatly improved, and the mechanical function of the product has been greatly improved, increasing the service life of the product. Compared to precision casting, the price is lower and the product is better.

Modifying the appearance quality of the rough casting, reducing cutting allowance, achieving high production rate and stable quality.Trial use for small and medium-sized products weighing between 1-100kg,

Due to the fast cooling speed during the casting process of coated sand molding, the graphite shape of the casting has been greatly improved, and the mechanical function of the product has been greatly improved, increasing the service life of the product. Compared to precision casting, the price is lower and the product is better.

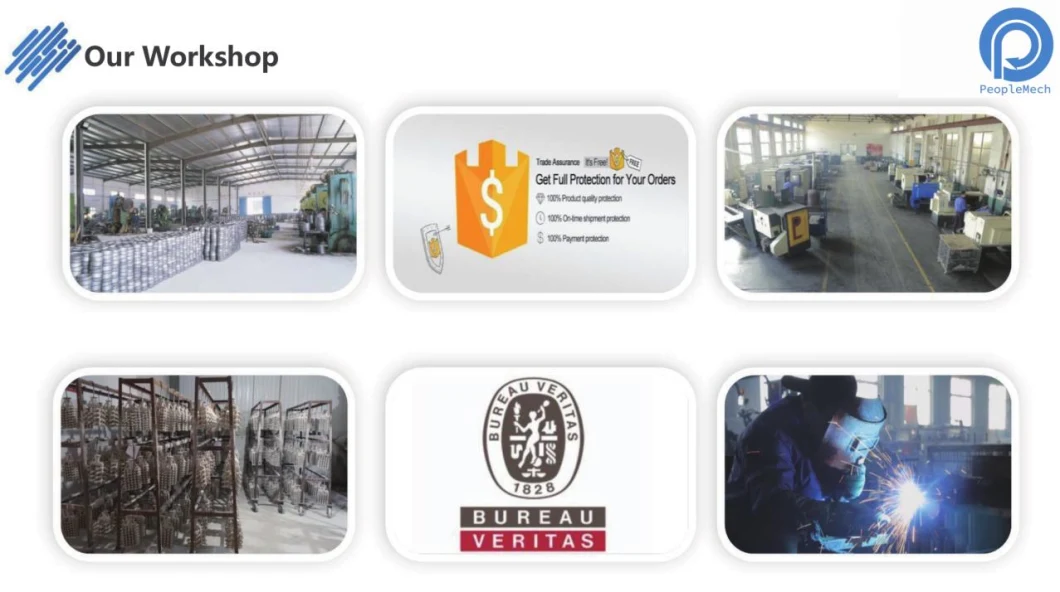

2. Workshop

3. Quality Inspection

4. Shipping

5. Cooperation

6. FAQ

1.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

2.What's the production time for new molds and mass production?

10-20 days to make the new moulds, mass production takes around 15 days,can process urgently if need.

3.Can you send me samples?

Yes, Samples are for free, and freight is on your side.

4.What kind of production service do you provide?

Mold making, all kinds of casting, CNC machining, stamping, plastic injection, assembly, and surface treatment.

5.What is the payment terms?

T/T: 30% deposit, the balance will be paid after B/L copy;

L/C: the balance irrevocable L/C at sight.

6.Why should you buy from us not from other suppliers?

Quicker response: 24 hours for quotation;

Dependable quality ISO9001;

Excellent Team Positive, flexible, passionate;

High business reputation Maintain long smooth relationship with clients.