Basic Info.

Model NO.

E-100F

Trademark

AMANDA

Origin

China

Production Capacity

5000ton/Month

Packaging & Delivery

Package Size

60.00cm * 45.00cm * 10.00cm

Package Gross Weight

25.100kg

Product Description

Product Description

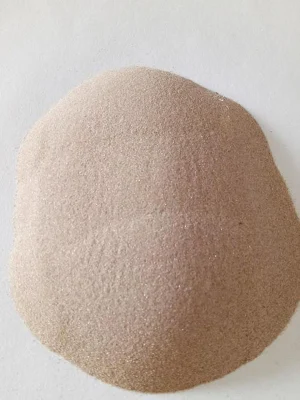

Zircon sand

Introduction:

Zircon sand, also known as zircon sand and zircon, is a mineral mainly composed of zirconium silicate. Pure zircon sand is colorless and transparent crystal, which is often dyed into yellow, orange, red, brown and other colors due to different origins and different types and quantities of impurities. 4.6~4.71, the change of specific gravity is sometimes related to the composition and alteration state. The cleavage of zircon is incomplete, the uniform Mohs hardness is 7~8, the refractive index is 1.93-2.01, and the melting point varies with the impurities contained within 2190~2420ºC fluctuation.

Zircon is a mineral composed primarily of zirconium, silicon, and oxygen that crystallized out of magma when igneous rocks formed. Zircon is also found in dikes and metamorphic rocks. It belongs to the tetragonal crystal system, often in the form of well-developed cone-shaped small square cylinders, and also irregular granular. Brittle, fractured shell-like. It is a high-quality refractory material. It is mostly symbiotic with ilmenite, rutile, monazite, xenotime, etc. in the coastal sand, and is obtained after separation by water separation, electric separation, magnetic separation and other beneficiation processes.

Product pictures:

Applications:

Zircon sand (zircon) is extremely resistant to high temperatures, with a melting point of 2750 degrees Celsius. And acid corrosion resistance. 80% of the world's direct use in foundry industry, ceramics, glass industry and the manufacture of refractory materials. A small amount is used in ferroalloys, medicine, paint, tanning, abrasives, chemical and nuclear industries. A very small amount is used to smelt metal zirconium.

Zircon sand containing ZrO265~66% is directly used as a casting material for iron metal in foundries because of its refractoriness (melting point above 2500ºC). Zircon sand has lower thermal expansion, higher thermal conductivity, and stronger chemical stability than other common refractory materials, so high-quality zircon has good adhesion with other various binders for the foundry industry. Zircon sand is also used as bricks in glass kilns. There are other uses for zircon sand and zircon powder mixed with other refractory materials.

Zircon sand (zircon) is used for refractory materials (called zirconium refractory materials, such as zirconium corundum bricks, zirconium refractory fibers), casting sand (precision casting sand) in the foundry industry, precision enamel utensils, and also used in In the production of glass, metals (sponge zirconium) and zirconium compounds (zirconium dioxide, zirconium oxychloride, sodium zirconate, potassium fluorozirconate, zirconium sulfate, etc.). It can be used to make zircon bricks for glass kilns, zircon bricks for ladles, ramming materials and castables; it can be added to other materials to improve its performance, such as adding zircon sand to synthetic cordierite, which can widen cordierite sintering range without affecting its thermal shock stability; adding zircon sand to high-alumina bricks to manufacture high-alumina bricks with resistance to spalling, the thermal shock stability is greatly improved; it can also be used to extract ZrO2. Zircon sand can be used as high-quality raw sand for foundry, and zircon sand powder is the main component of foundry coatings.

Zircon sand (zircon) and dolomite react together at high temperature to form zirconium dioxide or zirconium oxygen (ZrO2). Zirconium oxide is also a high-quality refractory material, although its crystal form changes with temperature. Stabilized zirconium oxide also contains a small amount of oxides of magnesium, calcium, scandium or yttrium. The melting point of stabilized zirconium oxide is close to 2700. It is resistant to thermal shock and is less reactive than zircon in some metallurgical applications. The stable zirconium oxide has low thermal conductivity, and it is harmless to use hafnium dioxide as a refractory in industrial zirconium oxide.

Zirconium in metallic form is mainly used in the chemical industry and the nuclear reactor industry, as well as in other industries that require corrosion resistance, high temperature resistance, special fusion properties or absorption of special neutrons. In the United States, about 8% of total zirconium consumption is used. For these industries, the only meaningful application of hafnium metal is in nuclear reactors on warships.

Zirconium metal is obtained by a multi-stage refining method. Initially, zircon is reacted with coke in an electric furnace to produce zirconium hydrocarbon hydride, and then chlorinated to produce zirconium tetrachloride. Magnesium reduction of zirconium tetrachloride (Thekrollprocess) involves the reduction of tetrachloride by placing magnesium metal in an inert gas to obtain spongy zirconium metal. High-purity zirconium metal can be refined by iodide thermal dissociation method. In this process, metal and iodine vapor react at a temperature of 200 ° C, and the volatile iodine is sent to the connector, making zirconium volatile. form of iodine and thus separated from most impurities. At a temperature of about 1300°C, the iodide is separated on the heated filament. High-purity zirconium is attached to the filament. The released iodine is transferred from the filament, and this product is called a zirconium rod.

Packing:

Logistics:

Q: Do you provide samples?is it free or extra?

A: Yes,we could offer the sample for free charge but do not pay the cost of freight.

Q: How about the price and quantity?

A: Factory price,Good quality and indicator of stability.

Q: How many years of experience in supply?

A: A long stable supplier

Q: Do you accept customization?

A: We could like to give you suitable suggestion about Fritted according to your detail application