- Overview

- Company Profile

- Product Description

- Quality Control

- Packaging & Shipping

- Warehouse

- Why Choose Us

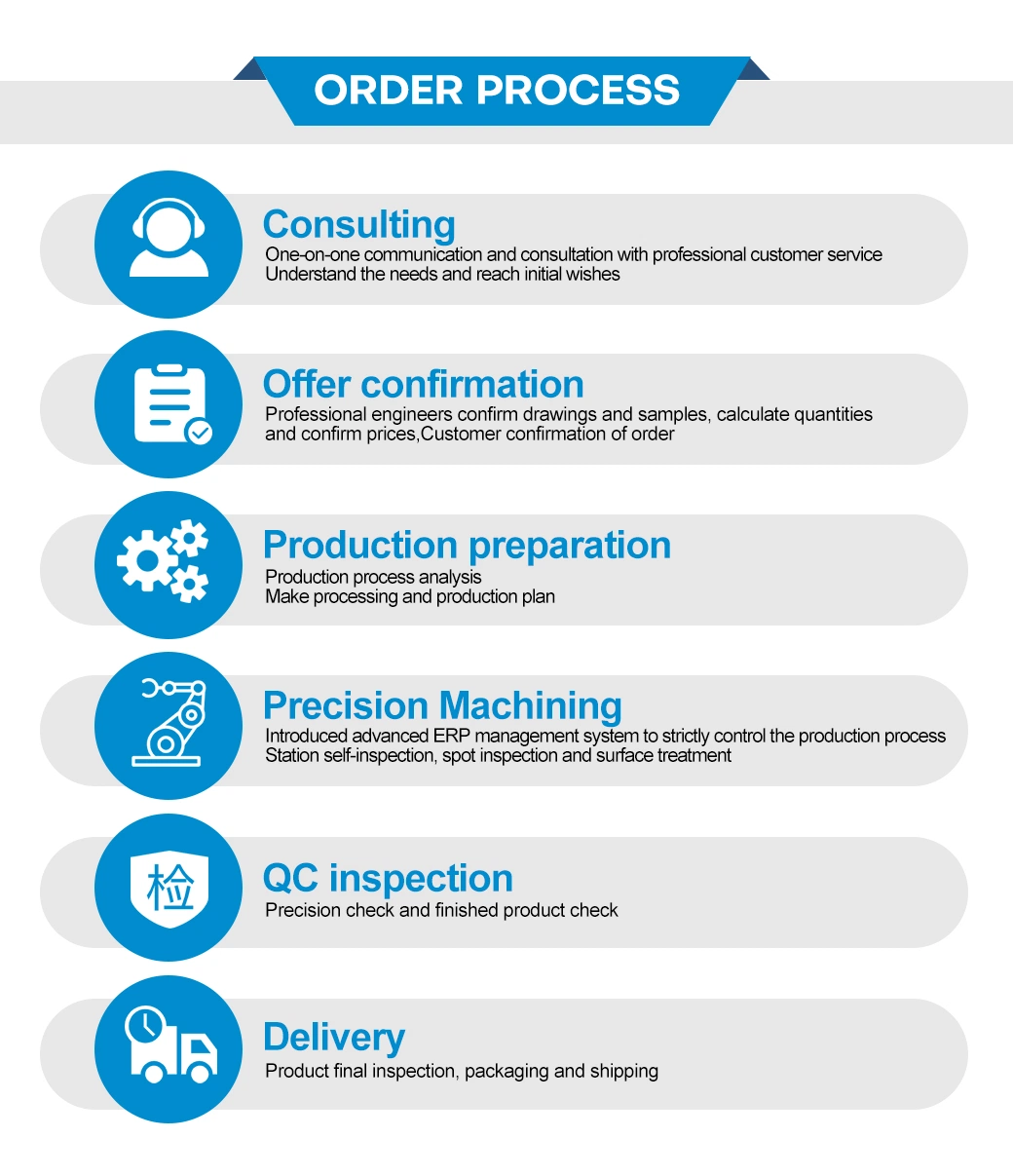

- Order Process

- FAQ

Basic Info.

Product Description

China Gray Iron Ductile Iron Sand Casting Manufacturer

Qingdao Nanchen supply OEM services of brass/steel/aluminum/iron/ stainless steel castings with Sand Cast Process, Investment Cast Process, Lost Wax Cast Process, Gravity Cast Process, Die Cast Process forging Process and CNC Machinery according to your requirements.

Whether you have a design ready for casting, or you need a custom casting design, we can help. Nanchen has the capabilities to produce it for your needs from start to finish.

| Casting Unit Weight | 0.1KG-3Tons | |

| Casting Standard | ISO ,DIN, AISI, ASTM, BS, JIS, etc. | |

| Casting Workpieces Size | Customized with the drawing you offered. | |

| Casting Workpieces Color | Silver, black, white, bronze, champagne, green, gray, golden yellow, nickel, or customized. | |

| Surface Roughness | Ra0.05-Ra50. | |

| Heat Treatment | Normalizing, Annealing, Quenching, Tempering, etc. | |

| Casting Material | High grade ductile iron(QT1050-6)/(QT800-5)/(QT600-5), Grey iron, Stainless steel, Carbon steel. | |

| Casting Process | Sand Casting | Iron based coated sand |

| Coated sand | ||

| Clay sand | ||

| Resin sand | ||

| Investment Casting | ||

| Lost Foam Casting | ||

| Vacuum process casting | ||

| Surface Finish | Sand Blasting, Anodizing, Powder coating, Wood grain, Polishing, Brushing, Electrophoresis. | |

| Inspection Equipment | Test equipment: Spectrum Analyzer, Hexagon CMM, Hardness test equipment, Tension test machine, E-coating testing equipments, Metalloscope. | |

| Dimension Inspection | Coordinate Measuring Machine (CMM),Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle and R Gauge,customized gauge, etc. | |

| Product application | Our products are widely used in many industries, such as automobile, truck, train, railway, fitness equipment, agricultural machinery, mining machinery, petroleum machinery, engineering machinery, shipbuilding, construction and other power equipment. | |

| Sample production cycle | 30-45 Working days. | |

Due to their increased strength and ductility, these types of castings are best used for:

| Value Bodies | Compressor Valves | Couplings | Sprocket Wheels |

| Hydraulic Valves & Cylinders | Structural Brackets | Rollers | Cable Drums |

| Frames | Pumps | Crankshafts | Camshafts |

| Exhaust Manifolds | Machine frames | Flanges | Hubs |

| Gear Boxes |

2. Sample and pilot run will be given 100% inspection during production and before shipment, Sample check for mass production according to ISDO standard or customer requirements

3. Test equipment: Spectrum Analyzer, CMM, Hardness test equipment, Tension test machine;

4. After-sales services are available.

5. Quality situation can be traceable.

Q1: How long is your delivery time?

A:Delivery time is depends on the total quantity of order. Normally, sample can be delivered within 2-3WEEKS.

Q2: Do you provide samples?

A:Yes, SAMPLE is available.

Q3: What is the MOQ of your products?

A:It depends on the category of order.

Q4: Where is your factory?

A:Our factory located in Qingdao city, Shandong province.

Q5:What does your company need to submit a quotation?

A:Drawing or Sample, together with relevant information, such as Quantity, Size, Weight, Material.

Q6:Can we place order without workpieces drawing?

A:Yes. We can duplicate the sample you offered and make drawing for your confirmation.