Basic Info.

Model NO.

investment casting

Application

Hardware

Material

Stainless Steel

Surface Preparation

Polishing

Surface Roughness

Ra12.5

Machining Tolerance

+/-0.02mm

Standard

DIN

Certification

ISO 9001:2000, Other

Dimensions Tolerance

Min +-0.02

Make

as Your Drawing or Sample

Max Manufacture Ability

100 Ton Each Month

Processing

Investment Casting

Applicastion

Hardware, Electronic Accessories, Machinery Parts,

Raw Material

Stainless Steel, Carbon Steel,

Transport Package

ISO Standard

Specification

OEM

Trademark

SEGER

Origin

Qingdao

Production Capacity

100 Ton Each Month

Packaging & Delivery

Package Size

8.00cm * 10.00cm * 5.00cm

Package Gross Weight

2.000kg

Product Description

Customized Stainless Steel Precision lost wax Investment Casting

We are skilled in investment casting, Materials vary from stainless steel,

carbon steel, aluminium alloy, bronze, brass, and so on.

The application are for Hardware, Electronic Accessories, Machinery Parts,

Agricultural Machinery Parts, Auto Parts, Furniture parts, Railway Parts,

Drainage System and etc.

With a flexible mind focused on the existing needs, our objective is to provide products,

services and solution that will enable our customers to become more competitive.

Process of Lost wax investment casting

Products show

Inspection Euqipment:

We have the chemical elements analysis centre and the mechanical testing centre

which include the following quality control measures:Spectrographic analysis,

magnaflux crack detection, ultrasonic detection, dynamic fatigue testing,

hardness testing, proof and ultimate breaking strength test...

TUV DIN EN ISO 9001: 2000 & ISO/TS16949 available

In order to ensure the quality of the orders,

our independent QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines.

We own automated casting lines, CNC machining, CMM inspection,

spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today.

We will sincerely create and share success with all clients.

PACKAGE:

FAQ:

Q1:what are seger's current lead times?

A1:Our lead times are dependent upon casting and finishing requirements,but generally are as follow:

30days after receipt the down payment usually.urgent need,please discuss with us to find a way out!

Q2:What file formats does Seger accept for drawings:

A2:The company ca accept a range of formats for drawings,but the main ones are detailed below:

2-D PDF AND TIFF 3-D STL,IGES,STEP,Solidworks,etc

Q3:Is it possible to visit seger to view it's manufacturing process?

A3:We are extremely proud of our facility and existing customers to visit our company.We think you will be impressed by us,as well as the warm welcome from our friendly,experienced team.

Q4:When are seger's offices open?

A4:the company's offices are open from 8.30am to 5.30pm,Mondays to Fridays.

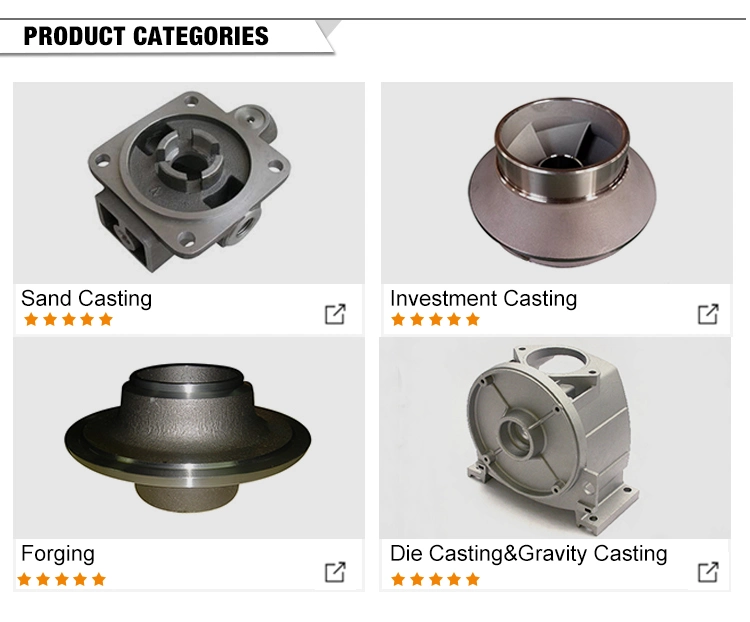

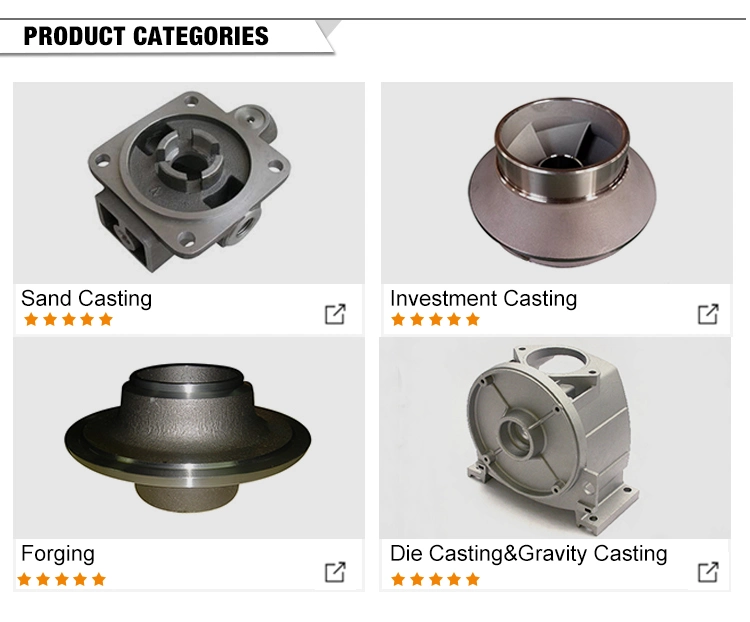

Main Technics we do

Overview

We are skilled in investment casting, Materials vary from stainless steel,

carbon steel, aluminium alloy, bronze, brass, and so on.

The application are for Hardware, Electronic Accessories, Machinery Parts,

Agricultural Machinery Parts, Auto Parts, Furniture parts, Railway Parts,

Drainage System and etc.

With a flexible mind focused on the existing needs, our objective is to provide products,

services and solution that will enable our customers to become more competitive.

Process of Lost wax investment casting

Products show

Inspection Euqipment:

We have the chemical elements analysis centre and the mechanical testing centre

which include the following quality control measures:Spectrographic analysis,

magnaflux crack detection, ultrasonic detection, dynamic fatigue testing,

hardness testing, proof and ultimate breaking strength test...

TUV DIN EN ISO 9001: 2000 & ISO/TS16949 available

In order to ensure the quality of the orders,

our independent QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines.

We own automated casting lines, CNC machining, CMM inspection,

spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today.

We will sincerely create and share success with all clients.

PACKAGE:

FAQ:

Q1:what are seger's current lead times?

A1:Our lead times are dependent upon casting and finishing requirements,but generally are as follow:

30days after receipt the down payment usually.urgent need,please discuss with us to find a way out!

Q2:What file formats does Seger accept for drawings:

A2:The company ca accept a range of formats for drawings,but the main ones are detailed below:

2-D PDF AND TIFF 3-D STL,IGES,STEP,Solidworks,etc

Q3:Is it possible to visit seger to view it's manufacturing process?

A3:We are extremely proud of our facility and existing customers to visit our company.We think you will be impressed by us,as well as the warm welcome from our friendly,experienced team.

Q4:When are seger's offices open?

A4:the company's offices are open from 8.30am to 5.30pm,Mondays to Fridays.

Main Technics we do

Overview

Technics Choice: Silica Sol investment casting or water glass investment casting

Certificate: ISO 9001-2000 ISO/TS16949 | |||||||||||||