Basic Info.

Model NO.

30/50 50/100mesh

Specification

SiO2>99.9%

Origin

China Lianyungang

HS Code

32074000

Production Capacity

8000mt/Year

Product Description

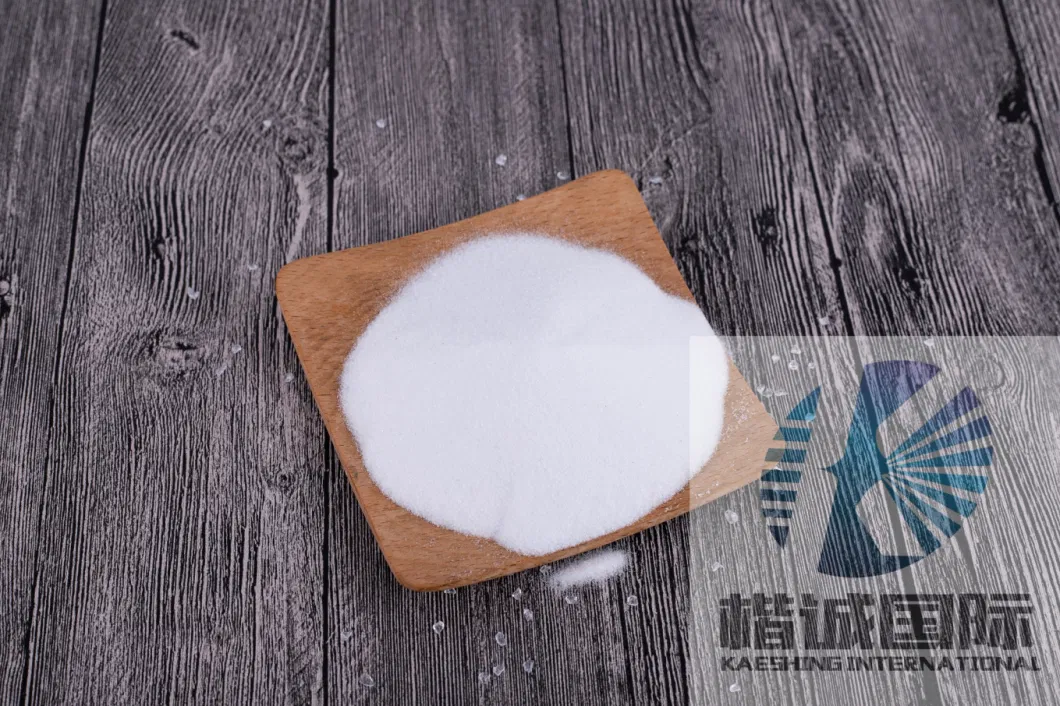

Fused Silica Pictures with dust and without dust:

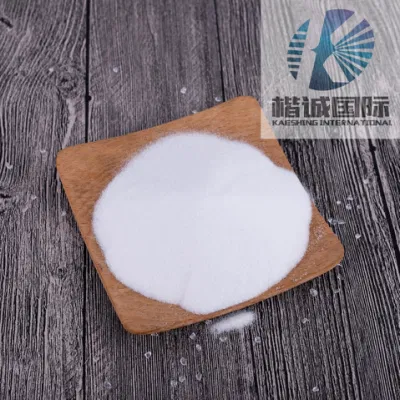

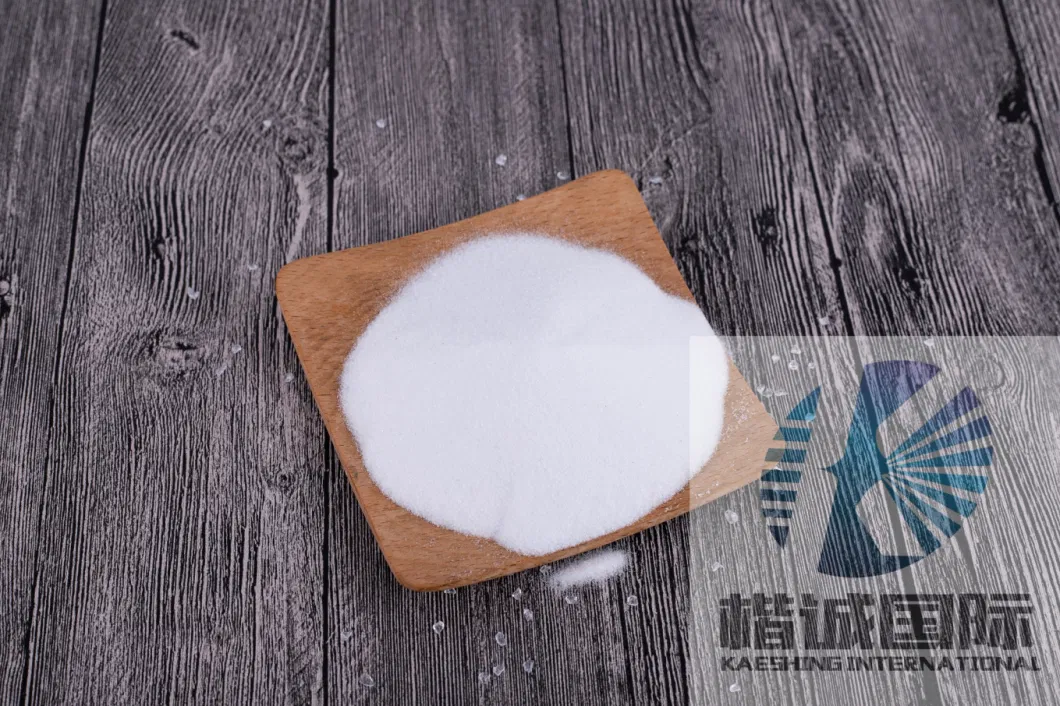

Dust Removal Fused silica Grains/sand is without dust:

Common Fused Silica with Dust:

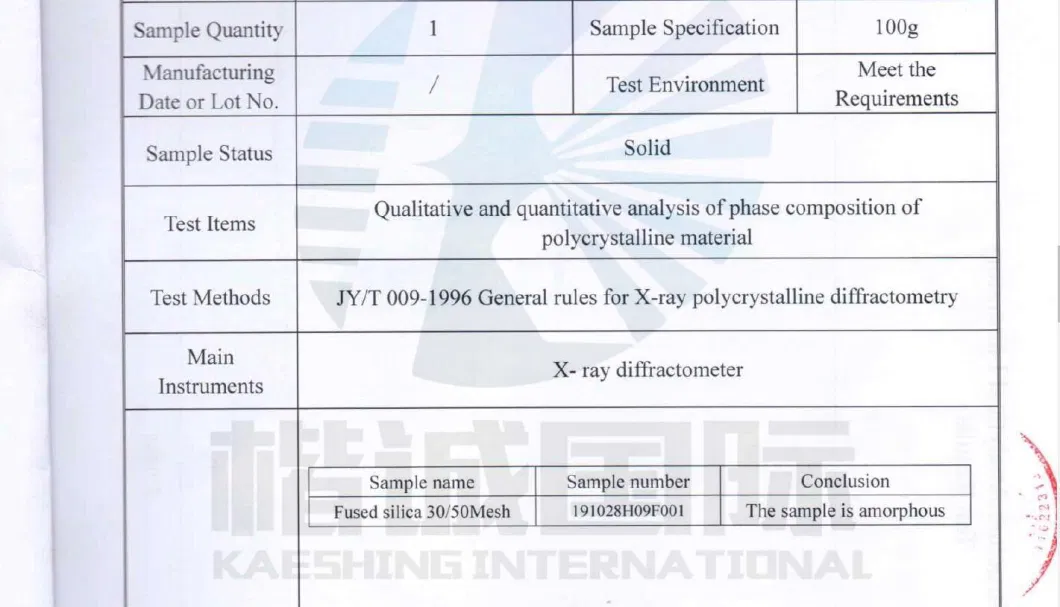

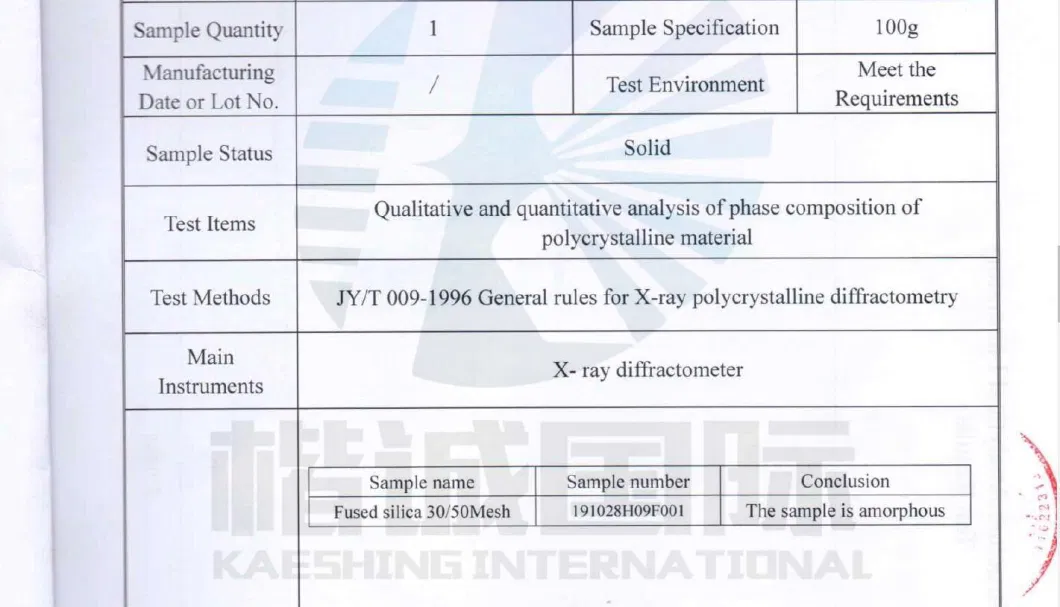

Fused Silica XRD Report:

Fused Silica Specifications:

3. Particle Size Distribution

*Pan designates the percentage of fused silica passing the last reported screen for each size.

Fused Silica Pictures:

Fused silica Package and Delivery:

Paper bags

Plastic Woven Bag of 25kg Net each,Then on Pallet:

Factory and Quality Control Pictures:

Dust Removal Fused silica Grains/sand is without dust:

Common Fused Silica with Dust:

Fused Silica XRD Report:

Fused Silica Specifications:

| 1. | Physical Properties | ||

| 1.1 | Composition | SiO2 | |

| 1.2 | Structure | Amorphous | |

| 1.3 | Colour | Transparent or white | |

| 1.4 | Melting Temperature | approx.1750ºC | |

| 1.5 | Specific Gravity | 2.21g/cm3 | |

| 1.6 | Hardness | 7 Mohs | |

| 1.7 | Thermal Expansion | 0.5*10-6 | |

2. | Chemical Properties | ||

| Grade A Plus | |||

| 2.1 | SiO2 | >99.9% | |

| 2.2 | Al2O3 | <100ppm | |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | |||

| 2.3 | Fe2O3 | <30ppm for grains <60ppm for powder | |

| 2.4 | CaO | <15ppm | |

| 2.5 | Na2O | <15ppm | |

| 2.6 | K2O | <15ppm | |

3. Particle Size Distribution

| Standard | |||||||

| 10-20 | 30-50 | 50-100 | -120 | -200 | -325 | ||

| Mesh | Microns | ||||||

| +8 | 2360 | <2 | |||||

| +12 | 1700 | 6-25 | |||||

| +16 | 1180 | 33-50 | |||||

| +20 | 850 | 25-45 | <1 | ||||

| +30 | 600 | 13 | 25-40 | ||||

| +40 | 425 | 32-45 | |||||

| +50 | 300 | 15-30 | <13 | ||||

| +70 | 212 | 30-60 | |||||

| +80 | 180 | 0-11 | <1 | ||||

| +100 | 150 | 28-51 | <10 | <1 | |||

| +140 | 106 | 4-16 | 7-13 | <10 | |||

| +200 | 75 | <2 | 10-15 | <10 | <3 | ||

| +325 | 45 | 14-20 | 15-30 | 4-11 | |||

| Pan | <3 | <2 | <1 | 45-55 | 70-80 | 86-97 | |

Fused Silica Pictures:

Fused silica Package and Delivery:

Paper bags

Plastic Woven Bag of 25kg Net each,Then on Pallet:

Factory and Quality Control Pictures: