- Home

- Horizontal servo energy saving injection molding machine

Energy Saving Horizontal Servo Injection Molding Machine Manufacturer in China

Introducing the latest innovation from Jiangsu Hongli Machine Co., Ltd. - the horizontal servo energy saving injection molding machine. This cutting-edge technology utilizes a horizontal design and servo motor to deliver precise and efficient operation, reducing energy consumption and production costs. With a focus on sustainability and productivity, this machine is ideal for a wide range of injection molding applications.

Designed with precision and performance in mind, the horizontal servo energy saving injection molding machine offers unparalleled accuracy and speed, resulting in high-quality finished products. Its user-friendly interface and advanced control system make it easy to operate, while its durable construction ensures reliability and longevity. Whether you are producing small components or large industrial parts, this machine provides the flexibility and efficiency needed to meet your manufacturing needs.

Experience the next level of injection molding technology with the horizontal servo energy saving injection molding machine from Jiangsu Hongli Machine Co., Ltd. Stay ahead of the competition and elevate your production capabilities with this state-of-the-art equipment.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

Automatic High Pressure Moulding Box Molding Line, Foundry Machine

Get top-quality Automatic High Pressure Moulding Box Molding Line and Foundry Machines from our factory. Our products ensure efficient and precise metal casting processes.

Self Hardening Sand Molding Production Line Resin Sand Molding Line

Get high-quality self-hardening sand molding and resin sand molding production lines at our factory. We offer reliable and efficient manufacturing solutions.

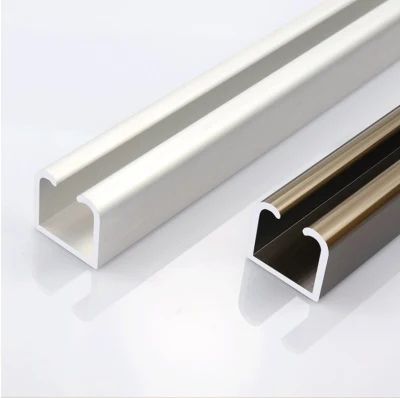

One Stop Solution Aluminium Alloy Solid Aluminum Track/Channel/Section Aluminum Mouldings

Looking for high-quality aluminum track, channel, and sections? Check out our One Stop Solution Aluminium Alloy Solid Aluminum Track/Channel/Section Aluminum Mouldings. We are a factory specializing in premium aluminum products.

Kraft 60grit Sand Paper Sheetfor Casting Hook and Loop

Get precision and durability with Kraft 60-grit sandpaper sheets for casting hook and loop. Our factory ensures top-quality products for your projects.

Auto Part Aluminum Alloy Die Cast Steel Gravity Casting for Truck Parts with Sand Blasting

Looking for top-quality auto parts? Our factory specializes in aluminum alloy die cast steel gravity casting for truck parts with sand blasting.

Grade B Fused Silica Sand 1-0.5mm Sio2 99.8% for Shell Material in Precision Casting

Get high-quality Grade B Fused Silica Sand 1-0.5mm Sio2 99.8% for precision casting shell material. We are a leading factory specializing in silica sand production.

Wooden Package Automatic Delynn Molding Sand Moulding Machine Dlzx6070h

Welcome to our factory! Get efficient and precise sand moulding with our Wooden Package Automatic Delynn Molding Sand Moulding Machine Dlzx6070h.

Green Environmental Protection Resin Sand Castings for Butterfly Valve Made in China Factory OEM Customized

Looking for high-quality green environmental protection resin sand castings for butterfly valves? Visit our China factory for OEM customized products.

High Quality 140/70-17 Motorcycle Tire Making Mould

Looking for a high quality 140/70-17 motorcycle tire making mould? Look no further! We are a factory that specializes in manufacturing top-notch tire making moulds. Satisfaction guaranteed!

Higher Class Aluminum Foil Container Making Mould

Get the best quality Higher Class Aluminum Foil Container Making Mould at our factory. We offer efficient and durable moulds for container production.

Furan Resin Sand Casting

Furan Resin Sand Casting: Get high-quality casted products from our factory. Expert in furan resin sand casting for durable and precise components.

Custom Aluminum Die Casting Zinc Alloy with Chroming Salt Spray Test 300h

Custom Aluminum Die Casting Zinc Alloy with Chroming Salt Spray Test 300h - We are a factory specializing in high-quality custom aluminum die casting and zinc alloy products.

China Customized Die Casting Zinc Alloy Aluminum Alloy Back of Mechaic Keyboard

Find high-quality China Customized Die Casting Zinc Alloy Aluminum Alloy Back of Mechaic Keyboard at our factory. Precision engineering for durable performance.

OEM Precision Iron Sand Casting Parts Gg25 Material Sand Casting Accessories

Explore our range of OEM Precision Iron Sand Casting Parts Gg25 Material Sand Casting Accessories. Made in our factory for reliable quality. Order now!

Ductile Iron Casting Ggg45 with Green Sand Cast

Ductile Iron Casting Ggg45 with Green Sand Cast - Quality products made in our factory. Contact us for durable and reliable casting solutions.

Sand Industrial Custom Fixturing Water Utilities Customized Auto Foundry Part By3d Printing Sand Casting & CNC Machining Refining Machinery

Sand Industrial Custom Fixturing offers high-quality custom parts for water utilities, auto foundry, and refining machinery using 3D printing, sand casting, and CNC machining. We are a leading factory in the industry.

China Supplier High End OEM Customized Auto Part Cylinder Head Rapid R&D Prototyping 3D Printing Sand Casting/Metal Casting /Low Pressure Casting/CNC Machining

Get high-quality auto parts with rapid prototyping and customized designs from our OEM factory. We specialize in 3D printing, sand casting, metal casting, and CNC machining.

OEM Casting Foundry Ductile Iron Sand Casting Automotive Spare Parts

Get high-quality Ductile Iron Sand Casting Automotive Spare Parts from our OEM Casting Foundry. As a factory, we ensure top-notch products at competitive prices.

Iron Casting Foundry Automatic Green Sand Horizontal Flaskless Moulding Machine for The Production of Hardware Accessories

Discover our Iron Casting Foundry Automatic Green Sand Horizontal Flaskless Moulding Machine for high-quality hardware accessories production. As a factory, we guarantee top-notch results.

OEM Metal Casting Factory Industrial Green Sand Casting Cast Iron Counterweight Manufacturer

Get high-quality cast iron counterweights from a leading OEM metal casting factory. We specialize in green sand casting for industrial applications.

- Energy Saving Horizontal Servo Injection Molding Machine Manufacturer

- Reviews

- Related Videos

Introducing our latest innovation in injection molding technology - the Horizontal Servo Energy Saving Injection Molding Machine. Designed to optimize energy efficiency and production output, this cutting-edge machine offers exceptional precision and performance for a range of industrial applications.

With its horizontal design, our servo energy saving injection molding machine maximizes space utilization while delivering superior stability and reliability. The advanced servo motor system ensures precise control of the injection process, resulting in reduced energy consumption and cost savings. Additionally, the innovative energy-saving design minimizes heat generation and noise, creating a more sustainable and productive working environment.

Equipped with state-of-the-art technology, our injection molding machine provides seamless integration with automation systems and industry 4.0 capabilities for enhanced productivity and process control. The user-friendly interface and intuitive controls allow for effortless operation and quick setup, enabling operators to achieve optimal production efficiency with minimal downtime.

Whether you are manufacturing automotive components, consumer goods, or medical devices, our Horizontal Servo Energy Saving Injection Molding Machine is the perfect solution for your injection molding needs. Experience the future of manufacturing with our innovative and high-performance machine, designed to meet the demands of the modern industry.

The horizontal servo energy saving injection molding machine is a game-changer in the manufacturing industry. With its innovative servo motor technology, this machine offers significant energy savings without compromising on performance. The horizontal layout allows for efficient operation and easy maintenance, making it a cost-effective solution for businesses. The injection molding process is precise and high-quality, thanks to the advanced servo system. Additionally, the machine is user-friendly and offers a variety of customization options to meet specific manufacturing needs. Overall, this injection molding machine is a reliable and efficient investment for any production facility.

Ms. Mary Zheng

I recently purchased the horizontal servo energy saving injection molding machine and I couldn't be happier with my decision. This machine has exceeded all my expectations with its high efficiency and energy-saving capabilities. The servo motor technology allows for precise control and reduces energy consumption, resulting in cost savings. The horizontal design provides excellent stability and allows for easy access for maintenance. The injection molding process is smooth and seamless, producing high-quality products every time. Overall, I highly recommend this machine to anyone in the manufacturing industry looking for a reliable and energy-efficient solution.

Mr. Vic lin

Contact us

Mr. Tracy huang: Please feel free to give your inquiry in the form below We will reply you in 24 hours