- Home

- Greensand casting for automotive industry

Greensand Casting for Automotive Industry: Top Manufacturer in China

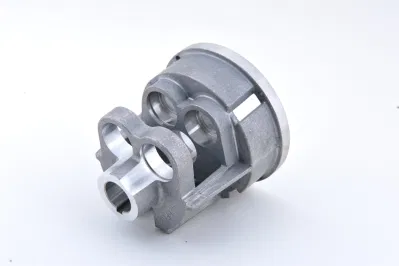

Introducing Jiangsu Hongli Machine Co., Ltd.'s advanced greensand casting technology, specifically designed for the automotive industry. Our cutting-edge equipment and processes ensure superior quality and precision in the production of automotive parts and components. Greensand casting is a cost-effective and flexible method that allows for efficient mass production while maintaining the integrity and durability of the final products.

At Jiangsu Hongli Machine Co., Ltd., we have perfected the greensand casting process to meet the high demands and standards of the automotive industry. Our state-of-the-art facilities and expert team ensure that each part is carefully crafted with the highest level of accuracy and consistency.

With our greensand casting technology, automotive manufacturers can rely on us to deliver top-quality parts that meet their specific requirements and contribute to the overall performance and safety of vehicles. Trust Jiangsu Hongli Machine Co., Ltd. for all your greensand casting needs in the automotive industry.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

Sand Flaskless Casting Molding Foundry Machine for Iron Mold Sand Casting Line

Looking for a reliable Sand Flaskless Casting Molding Foundry Machine for Iron Mold Sand Casting Line? Our factory offers high-quality products for all your casting needs.

A356 Aluminum Sand Casting Chair Base Part with T6

Looking for high-quality A356 Aluminum Sand Casting Chair Base Part with T6? Look no further! We are a factory specializing in producing top-grade chair base parts.

Professional Manufacturer CNC Precision Welding Part Zinc ODM Aviation Machinery Component

Get high-quality Professional Manufacturer CNC Precision Welding Part Zinc ODM Aviation Machinery Component at our factory. We specialize in precision manufacturing.

Professional Manufacturer Micro-Precise Welding Part Brass ODM Mining Machinery Component

Micro-Precise Brass Welding Part for ODM Mining Machinery Component - Professional Manufacturer. Factory-direct quality and customization.

Bronze Bushing/Copper Bushing/ Brass Seal Seat/Bronze Flange/Hardwares Made by Sand Casting

Bronze Bushing Factory - Quality Sand Cast Hardware for Industrial Use. Get durable bronze, copper, and brass components at competitive prices." Note: The product name and SEO description are based on the provided product information, and may be tailored to better suit the specific product and target audience.

Bronze Brass Copper Sand Caseting Foundry

Bronze Brass Copper Sand Casting Foundry - We are a leading factory specializing in the production of high-quality metal castings using the sand casting method.

PLC Customized Delin Wood Package Sand Casting Metal Moulding Machinery

PLC Customized Delin Wood Package Sand Casting Metal Moulding Machinery- Find top-quality metal moulding machinery at our factory. Contact us today!

High Hardness Garnet Sand for Water Jet Cutting

High Hardness Garnet Sand for Water Jet Cutting - Quality abrasive from our factory. Ideal for precise and efficient cutting. Contact us for bulk orders.

Qtj4-40b Hollow Block Making Machine Sand Cement Brick Mould Africa

Looking for a reliable hollow block making machine? Our Qtj4-40b model is perfect for producing sand cement bricks in Africa. Made in our factory." 🏗️ #constructionequipment #brickmakingmachine

Metal Casting Gg25 Gray Iron Sand Casting Connecting Rod for Auto Part

High-quality GG25 gray iron sand casted connecting rods for auto parts. We are a factory with expertise in metal casting. Order now!

Combined Three Layer Trapezoidal Sheet Iron Metal Roofing Roll Forming Machinery Corrugated Tile Metal Roofing Moulding Machine

Looking for high-quality metal roofing machinery? Our factory offers a Combined Three Layer Trapezoidal Sheet Iron Metal Roofing Roll Forming Machinery Corrugated Tile Metal Roofing Moulding Machine. Contact us for more information!

40-50 Minutes Sand Casting Aps International Standard Forging Melting Furnace

Introducing our advanced 40-50 Minutes Sand Casting Aps International Standard Forging Melting Furnace. We are a leading factory delivering high-quality products.

Zinc Die Cast Part/CNC Machining/Aluminum Alloy/Stainless Steel/Precision Die Casting

1. Precision Die Casting: High-Quality Parts Manufactured in Our Factory. Get Custom Zinc Die Cast Parts & More. Contact Us Today! 2. CNC Machining: Expertly Crafted Aluminum Alloy Parts in Our Factory. Precision Engineering for Your Needs. Inquire Now! 3. Stainless Steel: Durable and Reliable Products Made in Our Factory. Custom Designs Available. Request a Quote Today!

Custom Generator Engineering Exhaust Pipe Casting Processing Aluminum Alloy Lost Wax Sand Die Cast Vacuum Auto Service

Product Name: Custom Aluminum Alloy Exhaust Pipe Casting Description: We are a leading factory specializing in custom engineering, processing, and casting of aluminum alloy exhaust pipes for auto services.

Automatic HDPE Plastic Bottle Extrusion Blow Molding Machine

Get top-quality Automatic HDPE Plastic Bottle Extrusion Blow Molding Machine from our factory. We offer high-performance machines for efficient production.

Foundry Casting Equipment Static Pressure Machine

Get top quality foundry casting equipment, including static pressure machines, from our factory. Our products are designed for durability and precision.

25CrNiMo Stainless Steel Castings Subway Parts Sand Foundry

25CrNiMo Stainless Steel Castings Subway Parts Sand Foundry - We are a trusted factory producing high-quality stainless steel castings for subway components.

Custom Manufacturer of High Volume Production Ductile Iron Castings for The Automotive Industry

Discover top-quality ductile iron castings for automotive applications at our custom manufacturer factory. Contact us for high volume production services.

OEM Customized High End Rapid Prototype Impeller Pump Valve Part Supplier by 3D Printing Sand Casting Foundry Metal Casting/Low Pressure Casting/CNC Machining

High Quality Impeller Pump Valve Part Supplier, offering OEM Customized Rapid Prototyping and Metal Casting Services. Factory Direct, Fast Turnaround.

OEM Custom High Pressure Large Casting Resin Sand Cast Process Machine Tool Body Big Lathe Bed Casting

Get durable OEM Custom High Pressure Large Casting Resin Sand Cast Process Machine Tool Body Big Lathe Bed Casting from our factory. Quality guaranteed.

- Greensand Casting for Automotive Industry: Top Manufacturer and Exporter from China

- Reviews

- Related Videos

Introducing our cutting-edge greensand casting technology for the automotive industry. Our greensand casting process utilizes a mixture of sand, clay, and water to create a mold for the production of high-quality automotive components.

Our state-of-the-art greensand casting equipment, coupled with our team of experienced engineers, enables us to create complex and precision automotive parts with exceptional dimensional accuracy and surface finish. With our advanced greensand casting technology, we are able to produce a wide range of automotive components including engine blocks, transmission housings, and suspension parts.

Our greensand casting process is not only cost-effective but also environmentally friendly as it eliminates the need for harmful chemicals and reduces material wastage. By choosing our greensand casting technology, automotive manufacturers can benefit from reduced production costs and faster lead times without compromising on the quality and performance of the final product.

Furthermore, our greensand casting process allows for the integration of innovative design features and the production of lightweight yet durable automotive components. With our commitment to continuous improvement and customer satisfaction, we guarantee that our greensand cast automotive parts meet the highest industry standards.

Choose our greensand casting technology for your automotive component needs and experience the perfect blend of efficiency, sustainability, and quality.

The greensand casting process for the automotive industry is a game changer. The quality and precision of the castings produced are unmatched. The durability and strength of the casted parts are perfect for the demanding needs of the automotive industry. Additionally, the flexibility in design and shapes that can be achieved with greensand casting is impressive. This process has significantly reduced production costs and lead times, making it a reliable and cost-effective choice for automotive parts manufacturers. Overall, greensand casting is a top-notch choice for the automotive industry, offering high-quality and durable castings for a variety of automotive applications.

Mr. Jay Cao

I recently tried out greensand casting for the automotive industry and I must say, I am thoroughly impressed. The quality and precision of the castings produced are top-notch, making it perfect for automotive parts. The process is efficient and cost-effective, allowing for mass production without compromising on quality. The versatility of greensand casting also allows for the production of complex and intricate automotive components. Overall, I highly recommend greensand casting for anyone in the automotive industry looking for a reliable and high-quality casting method.

Mr. David Zhai

Contact us

Ms. Alice Zheng: Please feel free to give your inquiry in the form below We will reply you in 24 hours