- Home

- Exothermic riser sleeve ladle filtration

Top Exothermic Riser Sleeve Manufacturer for Ladle Filtration

Introducing the latest innovation in foundry technology - the Exothermic Riser Sleeve Ladle Filtration system, brought to you by Jiangsu Hongli Machine Co., Ltd.

This advanced system is designed to improve the quality and efficiency of metal casting processes. The exothermic riser sleeves are engineered to provide controlled expansion and superior insulation, ensuring optimal feeding and riser functionality. The ladle filtration system effectively removes impurities and enhances the cleanliness of molten metal, resulting in higher quality castings.

With the Exothermic Riser Sleeve Ladle Filtration system, foundries can expect reduced scrap rates, improved casting yields, and overall cost savings. Additionally, the innovative design of the system allows for easy installation and maintenance, making it a valuable investment for foundries of all sizes.

Trust Jiangsu Hongli Machine Co., Ltd. to deliver cutting-edge solutions for your foundry needs. Upgrade your casting operation with the Exothermic Riser Sleeve Ladle Filtration system today.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

Industrial Microseism Jolt Squeeze Moulding Machine for Foundry

Looking for high-quality jolt squeeze moulding machines for foundry? Our industrial microseism equipment is perfect for your factory needs.

OEM ODM Green Sand Cast Part Supplier Grey Iron/Ductile Iron/White Iron Shell Casting Sand Casting for Industrial Pump/Volute/Cover/Motor Housing

Looking for a reliable OEM ODM Green Sand Cast Part Supplier? Our factory specializes in Grey Iron/Ductile Iron/White Iron Shell Casting Sand Casting for Industrial Pump/Volute/Cover/Motor Housing.

Cheap Foundry Mold Plastic Injection Mould

Get quality cheap foundry mold plastic injection mould from our factory. High-performance, cost-effective solution for your molding needs.

OEM Customized Auto Motorcycle Spare Parts Rapid Prototyping Engine Block Prototype by 3D Printing Sand Casting Stainless Steel CNC Machining

Rapid Prototyping Engine Block Prototype by 3D Printing Sand Casting Stainless Steel CNC Machining. We are a factory specializing in OEM Customized Auto Motorcycle Spare Parts.

OEM Hot/Cold Chamber Aluminum Alloy/Zamak 5 Pressure Die Casting Zinc Camera Part

Get high-quality OEM Hot/Cold Chamber Aluminum Alloy/Zamak 5 Pressure Die Casting Zinc Camera Part. We are a factory specializing in producing top-notch camera parts.

Asis 8630 As3100 A4 Zg230-450 Metal Aluminium Ingot Cast Mould Aluminum Mold Making Sow Mould

Get high-quality metal aluminium ingot cast moulds from our factory. We specialize in aluminum mold making for various industrial applications. Contact us today.

Self Leveling No Bubbles 1: 1 Mixing Ratio Epoxy Crafts for Beginners

Get started on your epoxy crafts with our Self Leveling No Bubbles 1:1 Mixing Ratio Epoxy. Perfect for beginners. Buy direct from the factory.

Dust-Free Fused Silica Sand for Investment Casting

Get high-quality dust-free fused silica sand for investment casting from our factory. Perfect for creating precise and intricate metal parts.

Flask Mold Frame for Sand Casting Metal Casting Making Tool

Looking for a reliable flask mold frame for sand casting? Look no further! Our factory offers high-quality metal casting making tools for your industrial needs.

High Quality for CNC Machine Tools Casting Made Grey Iron Sand Casting

Looking for high quality CNC machine tools casting? Our grey iron sand casting is made with precision at our factory. Contact us for reliable products.

Foundry Sand Plant Resin Sand Process Production Line Furan Resin Sand Treatment Line

Explore our high-quality Foundry Sand Plant Resin Sand Process Production Line Furan Resin Sand Treatment Line. We are a factory committed to excellence.

Foundry Grey Iron Casting Green Sand Casting with CNC Machinery/Industrial/Agriculture/Mining Parts Wholesale Drawings

Foundry Grey Iron Casting Green Sand Casting with CNC Machinery/Industrial/Agriculture/Mining Parts Wholesale Drawings. We are a factory specializing in high-quality iron castings for various industries.

China Green Sand Molding Machine, Foundry Casting Machine

China Green Sand Molding Machine, Foundry Casting Machine available at our factory. Delivering high-quality products for all your casting needs.

Automatic Green Sand Molding Machine for Aluminum Casting Manhole Cover and Valve Produce

Discover our efficient Automatic Green Sand Molding Machine for high-quality Aluminum Castings. We are a factory specializing in manhole covers and valve production.

China Aluminum Alloy Foundry Supply Aluminum Green Sand Casting

China Aluminum Alloy Foundry provides high-quality Aluminum Green Sand Casting. As a factory, we are dedicated to supplying top-notch products.

China OEM Aluminum Alloy Gravity/Green Sand Casting with Grey/Ductile Iron

Shop for top-quality China OEM Aluminum Alloy Gravity/Green Sand Casting with Grey/Ductile Iron. We are a professional factory producing high-quality casting products.

Sand Cast Iron for OEM Parts Metal Durable Pattern Gray Ductile Valve

Get quality Sand Cast Iron for OEM parts from our durable and reliable factory. Choose from a variety of gray ductile valve patterns to fit your needs.

OEM Tree Grate Sand Casting Process for Ductile Iron Grey Iron Machined Parts

Explore our OEM Tree Grate Sand Casting Process for Ductile Iron Grey Iron Machined Parts. As a factory, we deliver high-quality products. Contact us now!

Factory Hot Selling S52 Centrifugal Regenerator Machine

Discover the high-performance Factory Hot Selling S52 Centrifugal Regenerator Machine. We are a leading factory dedicated to quality and innovation.

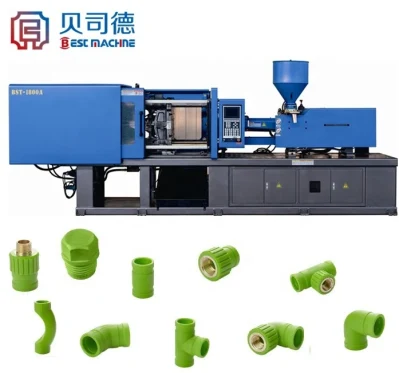

Best- 385 Plastic 1 Inch PVC Pipe Fitting Making Pipe Casting Injection Molding Machine

Get the best 1-inch PVC pipe fitting making machine from our factory. We specialize in plastic pipe casting and injection molding equipment.

- Exothermic Riser Sleeve Ladle Filtration Manufacturer in China

- Reviews

- Related Videos

Introducing our latest innovation in foundry technology – the Exothermic Riser Sleeve Ladle Filtration system. This groundbreaking system combines the benefits of exothermic riser sleeves with ladle filtration, to deliver superior results in metal casting processes.

The exothermic riser sleeves are designed to provide a consistent, uniform temperature profile during the solidification process, which minimizes shrinkage and porosity in the final casting. By incorporating ladle filtration into the system, we are able to further improve the quality of the metal by removing impurities and ensuring a clean pour every time.

Our Exothermic Riser Sleeve Ladle Filtration system is engineered to be easy to use and integrate seamlessly into existing foundry processes. The result is improved casting yield, reduced scrap, and lower overall production costs.

Furthermore, our system is designed to be environmentally friendly, with minimal waste and emissions. This makes it a sustainable choice for foundries looking to reduce their impact on the environment while maintaining high-quality casting standards.

In summary, our Exothermic Riser Sleeve Ladle Filtration system offers foundries a comprehensive solution for improving the quality and efficiency of their metal casting processes. With its innovative design and proven results, this system is set to revolutionize the way foundries approach metal casting.

I recently tried the exothermic riser sleeve ladle filtration for my casting process, and I must say I am thoroughly impressed. The exothermic properties of the riser sleeve not only improved the feeding efficiency but also resulted in a better surface finish on the castings. The ladle filtration system effectively removed impurities, leading to cleaner and high-quality castings. The overall performance of this product has significantly enhanced my casting process, and I highly recommend it to anyone in the foundry industry. It's a game-changer for sure!

Ms. Eleanor Deng

I recently tried out the exothermic riser sleeve ladle filtration system and I must say I was very impressed. The system was extremely efficient in removing impurities from the molten metal, resulting in a much cleaner and higher quality final product. The exothermic reaction also helped to keep the metal at the optimal temperature, reducing the risk of defects and ensuring consistency. Overall, the system was easy to use and highly effective, saving time and improving the overall quality of our castings. I highly recommend this product to anyone in the metal casting industry looking to enhance their production process.

Ms. Cony Wang

Contact us

Ms. Arya zhang: Please feel free to give your inquiry in the form below We will reply you in 24 hours