- Home

- Silicasol lost wax investment casting

Silicasol Lost Wax Investment Casting Manufacturer and Exporter from China

Introducing Jiangsu Hongli Machine Co., Ltd.'s cutting-edge silicasol lost wax investment casting technology. With over 20 years of experience in the industry, our company has mastered the art of creating high-precision parts using this advanced casting method.

Silicasol lost wax investment casting offers a superior level of detail and surface finish, making it ideal for complex and intricate components. By utilizing a high-quality silicasol binder, our process ensures that every detail of the original pattern is faithfully reproduced in the final product.

At Jiangsu Hongli Machine Co., Ltd., we take pride in delivering top-notch casting solutions for a wide range of industries, including automotive, aerospace, and medical equipment. Our state-of-the-art facilities and skilled technicians guarantee the highest level of quality and accuracy in every casting.

Experience the difference that silicasol lost wax investment casting can make for your products, and trust in Jiangsu Hongli Machine Co., Ltd. for all your casting needs.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

550X650mm Flaskless Automatic Horizontal Sand Molding Machine for

Get custom sand castings with our 550X650mm Flaskless Automatic Horizontal Sand Molding Machine. We are a leading factory specializing in sand casting production.

Taa Brand Hook Type Shot Blasting Machine Overhead Rail Shot Blast Machine in a Foundry

Taa Brand Hook Type Shot Blasting Machine is perfect for foundry applications. Overhead rail design ensures efficient shot blasting. Made in our factory.

Factory Price 2 Cavid 4 Cavities Semi Automatic Plastic Pet Mineral Water Bottle Blowing Blower Can Jar Making Maker Stretch Blow Molding Moulding Machine

Get the best deal on our Factory Price 2 Cavid 4 Cavities Semi Automatic Plastic Pet Mineral Water Bottle Blowing Blower. We are a leading maker of stretch blow molding machinery.

Chinese Factory OEM Resin Regeneration Sand Molding Line

Chinese Factory OEM Resin Regeneration Sand Molding Line. As a leading factory, we offer top-quality resin regeneration sand molding lines for industrial use.

Foundry Coke Metal Casting Filter 10X10mesh Sand Casting Aluminium Automotive Wheel

Foundry Coke Metal Casting Filter 10X10mesh for Sand Casting Aluminium Automotive Wheel. Factory direct quality for top performance in metal casting.

Abrasive Material Walnut Grit / Walnut Shell Powder / Walnut Sand 40#

Introducing our Walnut Grit 40# - perfect for industrial applications. As a factory, we produce top-quality walnut shell powder for all your abrasive needs. Shop now!

China Foundry Ductile Casting in Large Size CNC Machinery Part Gbt19001-2016 ISO9001-2015

Looking for high-quality large size CNC machinery parts made with China Foundry Ductile Casting? Our factory is ISO9001-2015 certified for superior products.

China Metal Casting Foundry Steel Product Customized Aluminum Iron Sand Die Casting

Top-quality China metal casting foundry offering customized steel, aluminum, iron, and sand die casting products. We are a trusted factory.

Densen Custom Car Spare Parts: Sand Casting Stainless Steel Replacement

Densen Custom Car Spare Parts specializes in sand-casting stainless steel replacements. As a factory, we guarantee top-quality and durable products.

Laser Milling Turning Grinding Precision CNC Machining Part Customized 3D Printing Sand Casting Aluminum Iron Stainless Steel Rapid Prototype

Precision CNC Machining Part: Customized Rapid Prototype. We are a factory specializing in laser milling, turning, grinding, and 3D printing services." Our factory specializes in providing precision CNC machining parts, including customized rapid prototypes. We offer a wide range of services, such as laser milling, turning, grinding, and 3D printing, using materials like aluminum, iron, and stainless steel.

High Quality OEM Sand Casting Resin Gray Iron Casting Ductile Grey Iron

Discover high-quality OEM sand casting resin gray iron casting ductile grey iron at our factory. We specialize in producing durable and reliable iron castings.

Custom Made Pump Body Housing Iron Sand Casting for Auto

Get high-quality custom made pump body housing iron sand casting for auto from our factory. We offer precision and durable products.

Motor Housing Motorcycle Engine Metal Auto Parts Vehicle Part Sand Casting Aluminum Alloy Ductile Iron Stainless Steel High Precision CNC Machining Parts

High Precision CNC Machining Parts - Custom Motor Housing, Motorcycle Engine, Metal Auto Parts. We are a leading factory specializing in sand casting, aluminum alloy, ductile iron and stainless steel products.

Metallic Casting White Metal Alloy Bearing Bushing Engine Bearing Alloy

Get high-quality Metallic Casting White Metal Alloy Bearing Bushing Engine Bearings Alloy from our factory. Durable and reliable products for your industry needs.

Yellow Removing The Sand Holes Burrs Wrinkles on Products Buff Grinding Cutting Polishing Paste Liquid

Name: SmoothEdge Factory Products Description: SmoothEdge Factory offers a range of high-quality products to remove sand holes, burrs, wrinkles, and polish surfaces.

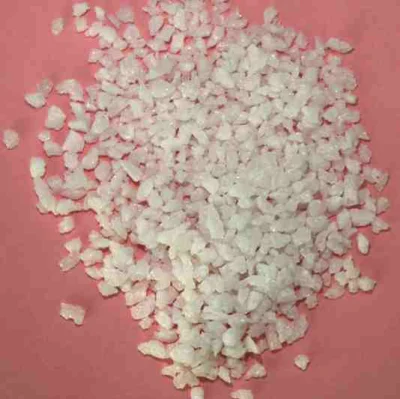

White Corundum Sand Suitable for Machinery and Petroleum

Discover our top-quality White Corundum Sand Suitable for Machinery and Petroleum at our factory. Trust us for reliable and durable industrial materials.

Casting Service Customized 3D Printing Sand Casting Mold Fabrication Foundry Pattern Aluminum Iron Steel Auto Part Rapid Prototyping & CNC Machining

CustomCast Pro: Specialized 3D Printing & Sand Casting Service. We're a leading factory for rapid prototyping & CNC machining of auto parts in aluminum, iron & steel.

China Horizontal Parting Flaskless Green Sand Casting Molding Machine and Automatic Molding Production Line

China Horizontal Parting Flaskless Green Sand Casting Molding Machine and Automatic Molding Production Line - We are a leading factory specializing in high-quality casting and molding equipment.

Foundry Fixed Type Sand Shakeout Machine Knockout Equipment Manufacturer

Foundry Fixed Type Sand Shakeout Machine Knockout Equipment Manufacturer - Your trusted source for high-quality factory equipment.

Bestech Factory Vibratory Conveyor Shakeout Cooling Drum

Bestech Factory's Vibratory Conveyor Shakeout Cooling Drum is designed for efficient materials handling and cooling. As a leading factory, we prioritize quality and innovation.

- Silicasol Lost Wax Investment Casting Manufacturer in China

- Reviews

- Related Videos

Introducing our Silicasol lost wax investment casting process, a premium method for creating intricate and high-quality metal parts. This specialized casting technique utilizes a silica-based binder, resulting in finer details and smoother surface finishes compared to other casting methods.

Our Silicasol lost wax investment casting process starts with a master pattern, from which a mold is created using a mixture of silica and a binder. Once the mold is formed, it is heated to remove the wax pattern, leaving behind a cavity in the shape of the desired part. Molten metal is then poured into the cavity, resulting in a precise and highly detailed final product.

This advanced casting process is ideal for producing parts with complex geometries, thin walls, and tight tolerances. The resulting parts have excellent surface finish, dimensional accuracy, and integrity, making them suitable for a wide range of industries such as aerospace, automotive, and medical.

At our facility, we are committed to delivering high-quality Silicasol lost wax investment cast parts that meet the most demanding specifications and requirements. Our experienced team and state-of-the-art equipment ensure that every part produced using this process meets the highest standards of quality and performance.

Choose our Silicasol lost wax investment casting process for your most challenging and intricate metal part needs, and experience the difference in quality and precision.

I recently used a Silicasol lost wax investment casting for a project and I was extremely impressed with the results. The precision and detail of the finished product was outstanding. The Silicasol material allowed for a smooth and flawless surface, which was crucial for the intricate design I was working on. The investment casting process also ensured that the final product had excellent dimensional accuracy and minimal surface imperfections. Overall, I highly recommend Silicasol lost wax investment casting for anyone looking for high-quality, detailed castings.

Ms. Kelly ZHU

I recently used a Silicasol lost wax investment casting for a project and I must say I was thoroughly impressed with the results. The precision and detail achieved with this casting method were exceptional. The smooth surface finish and high dimensional accuracy of the final product were exactly what I was looking for. The Silicasol material proved to be incredibly durable and was able to withstand high temperatures without any issue. The casting process was also relatively fast and efficient, which saved me a lot of time and hassle. Overall, I highly recommend Silicasol lost wax investment casting for anyone looking for high-quality and precise results.

Ms. Tracy Lin

Contact us

Ms. Sandy Ms: Please feel free to give your inquiry in the form below We will reply you in 24 hours