- Home

- Resin sand process production line

Resin Sand Process Production Line Manufacturer in China

Introducing the Resin Sand Process Production Line by Jiangsu Hongli Machine Co., Ltd. This production line is equipped with advanced technology and is designed for efficient and high-quality casting production. The resin sand process ensures that the sand molds are strong and durable, producing precise and smooth castings. With a focus on automation and control, this production line is capable of producing a wide range of casting products with consistent quality and accuracy. Jiangsu Hongli Machine Co., Ltd. is committed to providing reliable and innovative solutions for the foundry industry, and the resin sand process production line is a testament to their dedication to excellence. Whether it's for automotive, aerospace, or general engineering applications, this production line is the ideal choice for businesses looking to enhance their casting production capabilities. Trust Jiangsu Hongli Machine Co., Ltd. for top-notch, reliable, and high-performing foundry equipment.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

Colorful Anodizing Brushing Polishing Aluminium Metal Aluminum Extrusion Moulding

Colorful Anodizing Brushing Polishing Aluminium Metal Extrusion Moulding Factory. High-quality custom products for all your aluminum needs.

Foundry OEM Sand Casting Metal Parts Cast Gray Ductile Iron for Machinery Parts Gear Pump Steel Aluminum Lost Wax Casting Part

Foundry OEM Metal Parts: Cast Gray Ductile Iron for Machinery Parts Gear Pump Steel Aluminum Lost Wax Casting. Factory-direct quality castings.

Foundry Material Grey Iron Casting Silicon Carbide Ceramic Foam Filter 100X150X22mm Bronze

Get high-quality Grey Iron Castings with Silicon Carbide Ceramic Foam Filters 100X150X22mm Bronze. Our factory ensures top-notch products. Order now!

Precision Casting Fused Silica Sand

Get high-quality precision casting fused silica sand from our factory. Our product is ideal for high-precision casting applications. Contact us today!

Sand Casting Housing Manufacturer Large Steel Sand

Get high-quality sand cast steel housings from a reputable factory. As a leading manufacturer, we offer durable and reliable products for various applications.

Refractory Material White Corundum Section Sand Specification 5-3

Get top quality Refractory Material White Corundum Section Sand 5-3 from our factory. Best specifications and affordable prices. Order now!

OEM Lost Wax Foam Clay Coated Resin Sand Gravity Metal Ceramic Mold Precision Investment Dewaxing Low Pressure Die Carbon Alloy Brass Casting

Precision Investment Casting Factory - Offering a wide range of casting services including OEM Lost Wax, Foam Clay, Resin Sand, and more. Contact us for high-quality metal and alloy castings.

C17200 C17500 C5191 50mm Thick Customized 99.99% Copper Plate Sheet for Construction

Get high-quality customized 99.99% copper plate sheets for construction from our factory. Choose from C17200, C17500, and C5191 in 50mm thickness.

Casting Delynn Wooden Package Iron Green Sand Molding Machine with CE

Casting Delynn Wooden Package Iron Green Sand Molding Machine with CE at our factory. High-quality and efficient production process. Contact us today!

Quartz Silica White Sand for Pool

Get the best quality Quartz Silica White Sand for Pool from our factory. Perfect for pool filtration, our sand ensures crystal-clear water.

Clay Sand Casting OEM Clay /Furan Aluminum/Iron/Brass Sand Casting

Custom Clay Sand Casting Services - OEM Aluminum, Iron, and Brass Sand Casting. We are a factory dedicated to producing high-quality metal castings.

Popular China Manufacture Customized Fabrication Service Coated Ductile Iron Sand Casting for Truck/Car/Agriculture/Flywheels/Pump Body

Looking for high-quality coated ductile iron sand casting for various applications? Our China-based factory offers customized fabrication services for truck, car, agriculture, flywheels, and pump bodies.

KOCEL Customized Sand Mold for Auto Spare Parts by Rapid Prototyping with 3D Printing Sand Casting & CNC Machining for Stainless Steel Metal Parts

Introducing KOCEL's Rapid Prototyping with 3D Printing Sand Casting & CNC Machining for Stainless Steel Metal Parts. We are a premier factory for custom auto spare parts.

Sand Casting Ht250 Housing for Forklift with Painting

Get high-quality Ht250 housing for forklifts with sand casting and painting from our factory. Durable and reliable products at competitive prices.

Factory Price Customized Gray Iron Ductile Iron Sand Casting Black Color Hydraulic Parts

Discover high-quality, customized gray iron and ductile iron hydraulic parts with factory pricing. Our sand casting process ensures durable and reliable products.

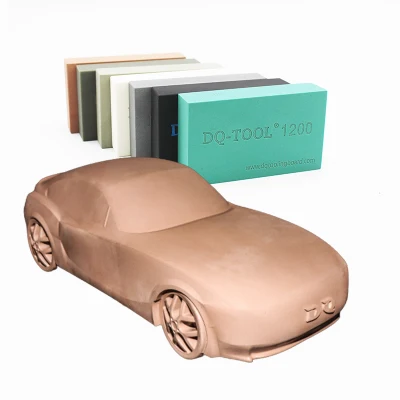

Paper and Paperboard Tooling Polyurethane Board Rapid Sand Casting Foundry Soft Tooling

PolyCast: High-quality paper and paperboard tooling for rapid sand casting foundry. We are a leading factory in the production of soft tooling materials.

Custom Made Sand Casting and Machining Gearbox Painted Parts

Custom Gearbox Painted Parts: High-quality sand casting and machining from our factory. Get durable and precision-engineered components for your machinery.

Machine Custom Foundry Parts Metal Stainless Steel Aluminium Zinc Alloy Sand Die Casting CNC Service for Auto Parts

Custom Foundry Parts: Stainless Steel, Aluminium, Zinc - CNC Service for Auto Parts. Factory direct for quality metal casting. Get a quote now!" (Meta Description: We are a leading factory providing custom foundry parts such as stainless steel, aluminium, and zinc alloy, with CNC service for auto parts. Get a quote now!)

HDPE Oil Bottle Jerrycan Fully Automatic Blow Moulding Machine

We are a factory that specializes in producing HDPE Oil Bottle Jerrycan Fully Automatic Blow Moulding Machines. High-quality and efficient production guaranteed.

China Factory Pouring Machine for Molding Line, Casting Machine

Discover our top-quality China Factory Pouring Machine for Molding Line and Casting Machine. We are a leading factory with advanced technology.

- Resin Sand Process Production Line Manufacturer in China

- Reviews

- Related Videos

Introducing our state-of-the-art Resin Sand Process Production Line, designed to revolutionize the manufacturing of high-quality metal castings. This innovative production line is equipped with advanced technology and precision engineering to ensure superior performance and efficiency.

The Resin Sand Process Production Line is capable of handling a wide range of casting requirements, from small intricate components to large and complex parts. With its automated system, it offers unparalleled flexibility and versatility, allowing for quick and seamless production of various casting designs.

Our production line is built to deliver consistent and uniform mold quality, resulting in superior casting finish and dimensional accuracy. The advanced resin sand process used in this production line ensures superior mold strength and stability, leading to reduced casting defects and rework.

In addition to its superior performance, our production line is also designed with sustainability in mind. It incorporates energy-efficient technologies and materials, minimizing environmental impact and reducing overall production costs.

Whether you are in the automotive, aerospace, or general engineering industry, our Resin Sand Process Production Line is the perfect solution for your casting needs. With its cutting-edge technology and unparalleled performance, it is set to elevate your manufacturing capabilities and drive your business to new heights.

The Resin sand process production line is a game-changer for product manufacturers. With its efficient and precise production process, it ensures high-quality and uniform products every time. The advanced technology used in this production line guarantees a smooth and seamless workflow, resulting in increased productivity and reduced manufacturing costs. The resin sand process also allows for easy customization and flexibility, making it ideal for a wide range of product types. Overall, the Resin sand process production line is a must-have for any manufacturer looking to streamline their production process and deliver top-notch products to their customers.

Ms. Polinna Cheung

I recently purchased the resin sand process production line for my manufacturing business and I am extremely satisfied with the results. The equipment is well-designed and robust, making it easy to operate and maintain. The resin sand process has significantly improved the quality and efficiency of our production line. The finished products have a smooth and refined surface, and the casting process is now more streamlined and precise. Overall, this production line has exceeded my expectations, and I highly recommend it to any business in need of a reliable and efficient resin sand process solution.

Ms. Kathy Kathy

Contact us

Ms. Susan Zhou: Please feel free to give your inquiry in the form below We will reply you in 24 hours