Basic Info.

Model NO.

Y83

Grade

Manual/ PLC

Packaging Material

Film, Box etc

Cooling System

Yes

Driven Type

Hydraulic System

After-Sales Service Provided

Engineers Available to Service Overseas

Export Markets

Global Market

Machine Colour

Customer Pointed

Transport Package

Seaworthy

Specification

CE and ISO9001: 2000

Trademark

DFS

Origin

China

HS Code

846291900

Production Capacity

30 Sets / Month

Product Description

Y83-630 Alloy Casting Four-Column Automatic Briquette Machine (factory)

| Y83 SERIES HYDRAULIC BRIQUETTING PRESS | |||||

| Model | Nominal Force (kn) | Aux.Cylinder Press(kn) | Power(kw) | Production(kg/h) | Bale Size(*H)(mm) |

| Y83-250 | 2500 | 60 | 30 | 1000~1500 | 90*(50~80) |

| Y83-360 | 3600 | 100 | 30 | 1200~2000 | 110*(50~80) |

| Y83-400 | 4000 | 100 | 30 | 1800~2600 | 120*(70~130) |

| Y83-500 | 5000 | 100 | 30 | 2000~3000 | 130*(70~130) |

| Y83-315 | 3150 | 100 | 30 | 1200~1500 | 100*(50~80) |

| Y83-630 | 6300 | 100 | 30 | 2200~3600 | 150*(70~130) |

What is the Applications and Features of our products?

Applications:

Y83 series hydraulic briquetting press (Chip packing machine) is to melt down and compress metal chips into briquettes by cold pressing technology. Those briquettes are 3-6 kg each, and they can replace waste steel, copper, iron or aluminum as row materials, so it is benefit for reducing burning of metal. It is easy for store and transportation. It is no need to warm up, add additives or other craftwork during the whole progress of work. After pressing, the block's density can reach 5-6 Ton/M3 (without any adhesive).

1.Coal powder/coal fine/coal dust

2.Package and Shipping: Applications:

Y83 series hydraulic briquetting press (Chip packing machine) is to melt down and compress metal chips into briquettes by cold pressing technology. Those briquettes are 3-6 kg each, and they can replace waste steel, copper, iron or aluminum as row materials, so it is benefit for reducing burning of metal. It is easy for store and transportation. It is no need to warm up, add additives or other craftwork during the whole progress of work. After pressing, the block's density can reach 5-6 Ton/M3 (without any adhesive).

1.Coal powder/coal fine/coal dust

2.Charcoal powder/charcoal fine/charcoal dust

3.Gypsum/Desulfurization Gypsum/quicklime/slaked lime/

4.Activated carbon/carbon black

5.All kinds of metal powder/Manganese/magnesium/copper/iron

6.Iron oxide/aluminum oxide/clay

7.Some other type powder.

Package : Seaworthy package ( Film package,Naked package or Shrink-pack).

3.Our serivce:

24 hours online service

Enquiry will be replied in 2 hours

One year guarantee and lifelong maintenance.

Spare parts: supply one set of spare parts for free, tool box, operation book.

Free parts for any breakdown with convincing evidence

Any problem, you can call usdirectly.

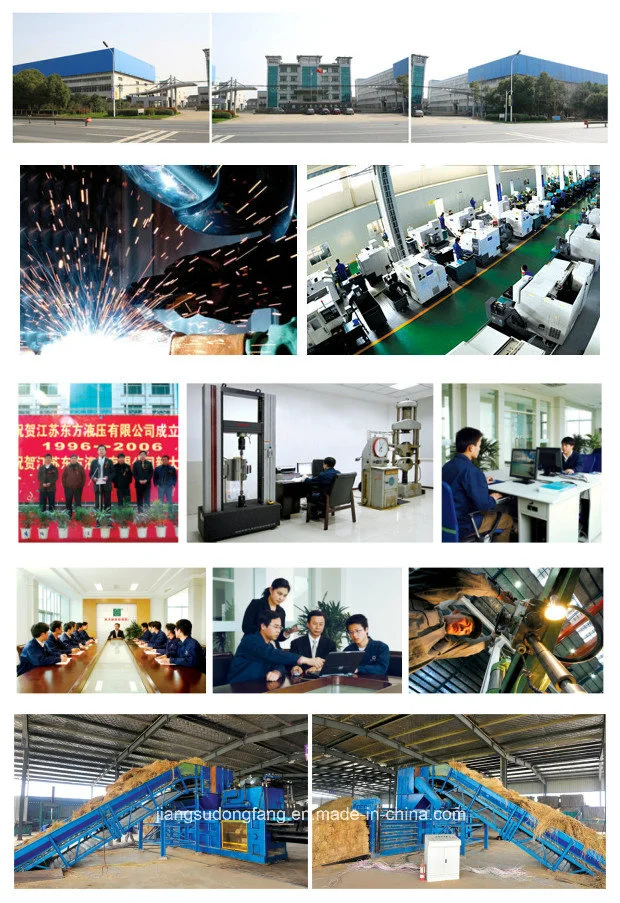

4.Company information:

Jiangsu DONGFANG Hydraulic Co., Ltd. locates at Jiangyin city at the south bank of golden river with beautiful landscape, comfortable climate, convenient land and water traffic.

Our company is an enterprise specialized in producing the renewable resources recycling equipmentwith rich experience of professional design and production. Leading products: Y81 series metal hydraulic baler, Y82 series metal & non-metal hydraulic baler, Y83 series hydraulic briquetting press, Y32 series four- colume hydraulic press, Q43 series alligator metal shear, Q15 series square sheet shears, EPM series waste paper baler etc. more than a dozen major series of hundreds of varieties.

Our company always takes the quality and credit standing as the first, we own over 10 national patents, keeps on innovation of technology, supplies customers with the very professional service. We are confirmed with ISO9001 quality system and CE quality system.

5.FAQ:

Q1: How can i get the after-service?

A: We provide one year guarantee and lifelong maintenance.

We will send you the spare parts by free if the problems caused by us.

If it is the men-made problems,we also send the spare parts,however it is charged.

Any problem, you can call us directly.

Q2: Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

Our factory address: Yun ting industrial pack, ZhouZhuang Town, Jiangyin, Jiangsu P.R China

Our factory is near Shanghai Pudong Airport.We can pick you up in the airport.

Hotel booking service is available .

Q3:Are you a factory or trade company?

A:We are manufacturer with own factory for 20 years, export proportion 50~60%.

Q4:How can i trust your company?

A:With 20-years-professional design, we can provide you suitable suggestion and lowest price

1. Assessed by third party, national patents and CE, ISO for all equipment, .

2. Welcome to inspect anytime. We are near to Shanghai Pudong airport.

3. For our machine, we do very well on hydraulic balers,hydraulic shears.

Q5 :Is your price competitive?

A: Only good quality machine we supply. Surely we will give you best factory price based on

superior product and service.

Send your inquiry Details in the Below Box , Click "Send" Now !