Basic Info.

Model NO.

FS-A

Fe2o3

<0.003%

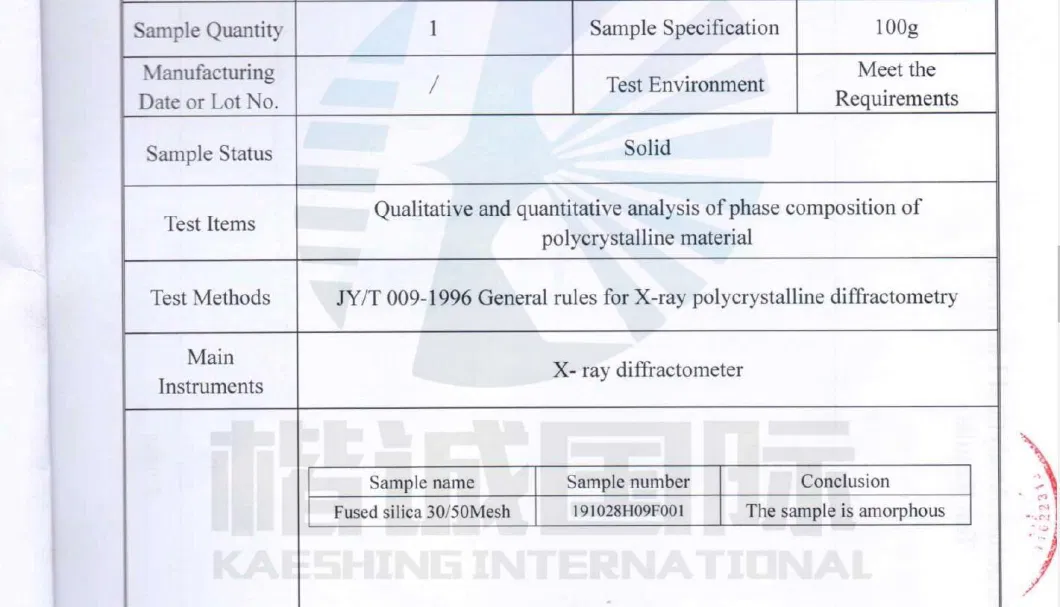

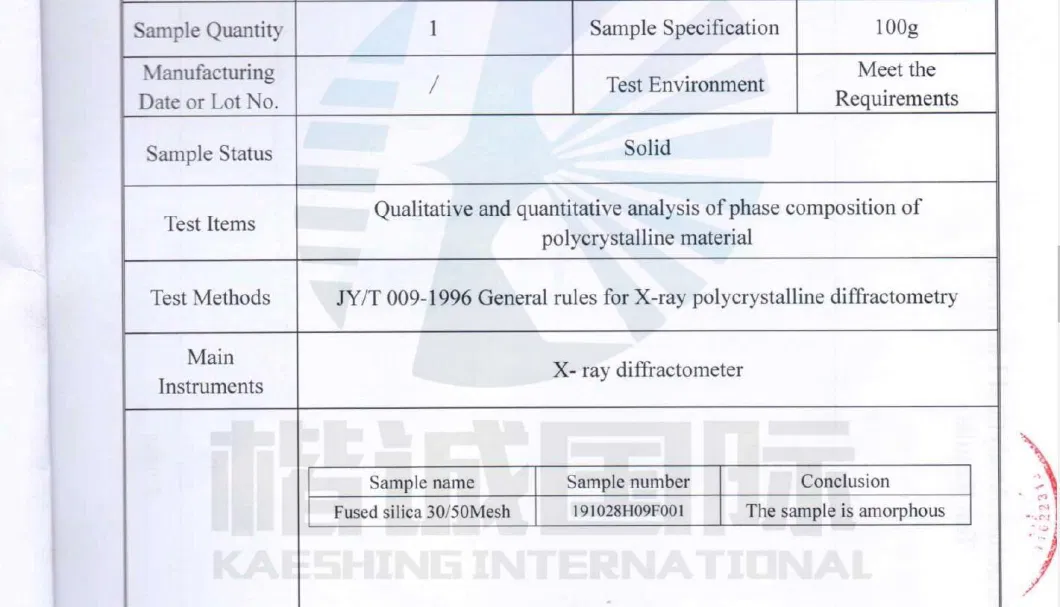

Xrd Test Result

Amorhous

Density

2.2g/cm3

Al2O3

<200ppm

K2o

<20ppm

Na2o

<20ppm

Magnetics

<30ppm

Transport Package

Plastic Woven Bag, Paper Bag, Big Bag, Pallet

Specification

SiO2>99.9%

Trademark

Kaeshing

Origin

China Lianyungang

HS Code

32074000

Production Capacity

8000mt/Year

Product Description

We'd like to send free samples for Purpose of test,Research and Development.

Fused Silica sand XRD Report:

Fused Silica is made of high purity crystal silica from China Donghai-Xinyi by electrically fusing (fusing temperature 1800-2000ºC) to amorphous Silicon dioxide, then is specially engineered into lumps,cullet, ingots, sand,grain,granular and powder flour form designed for making PV fused silica crucible,thermal ceramic,refractory,EMC investment casting ceramic shell etc.

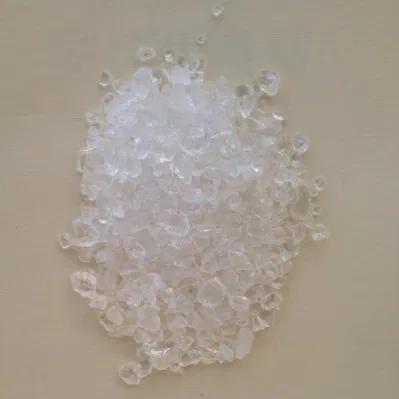

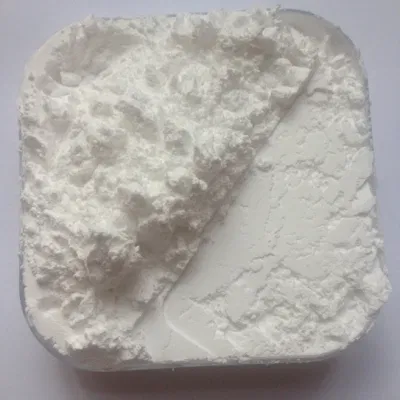

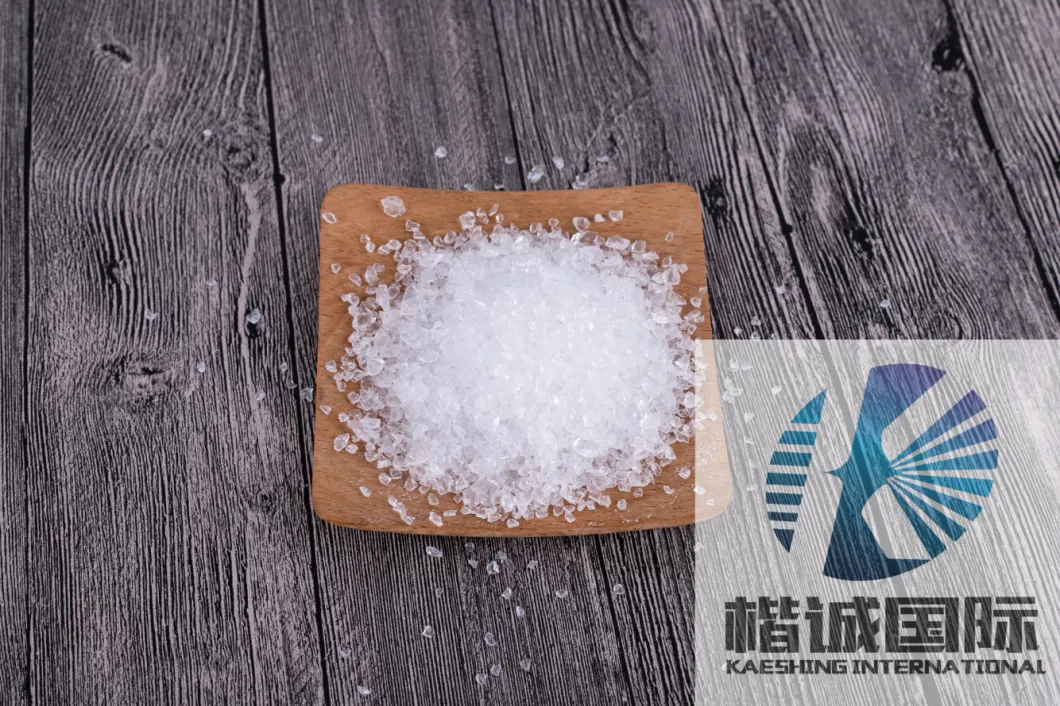

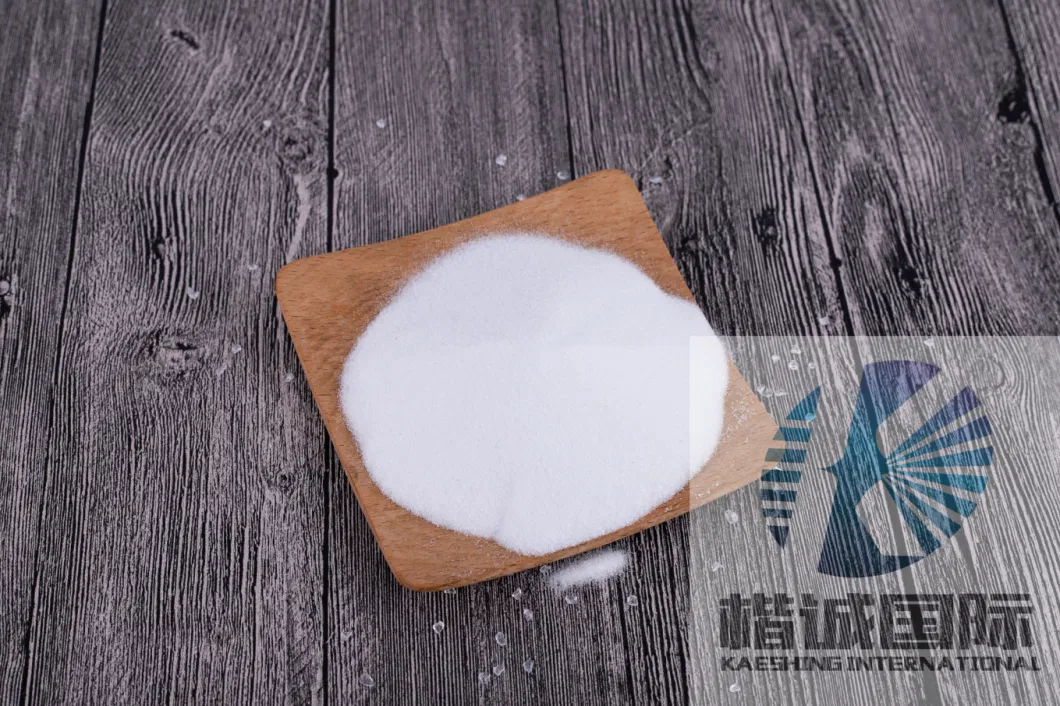

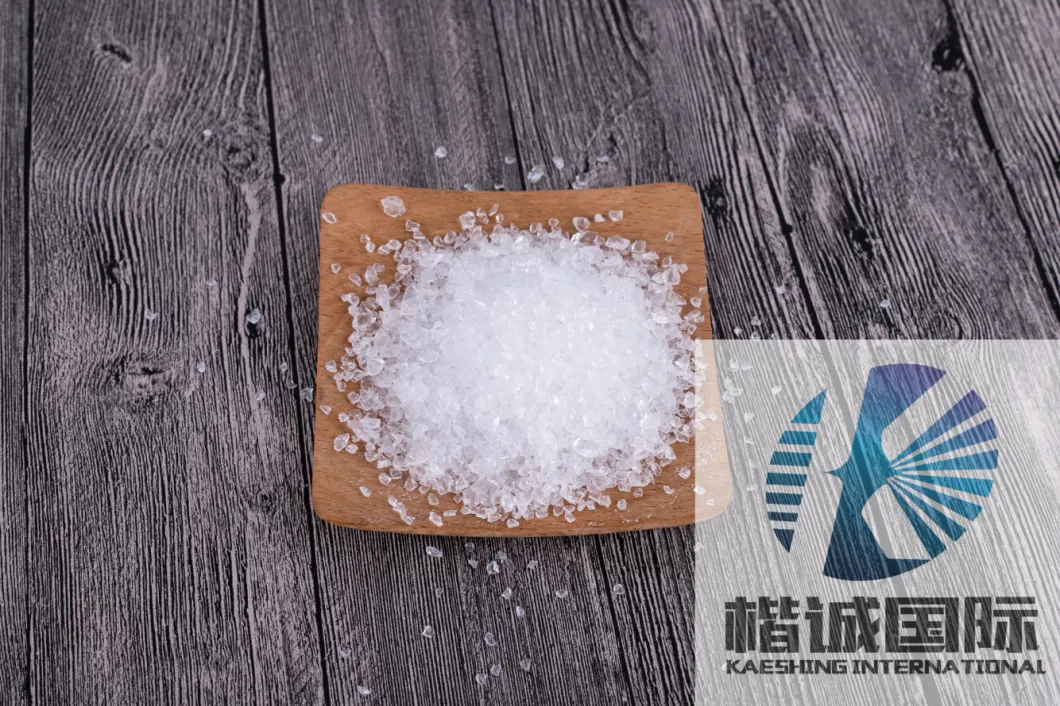

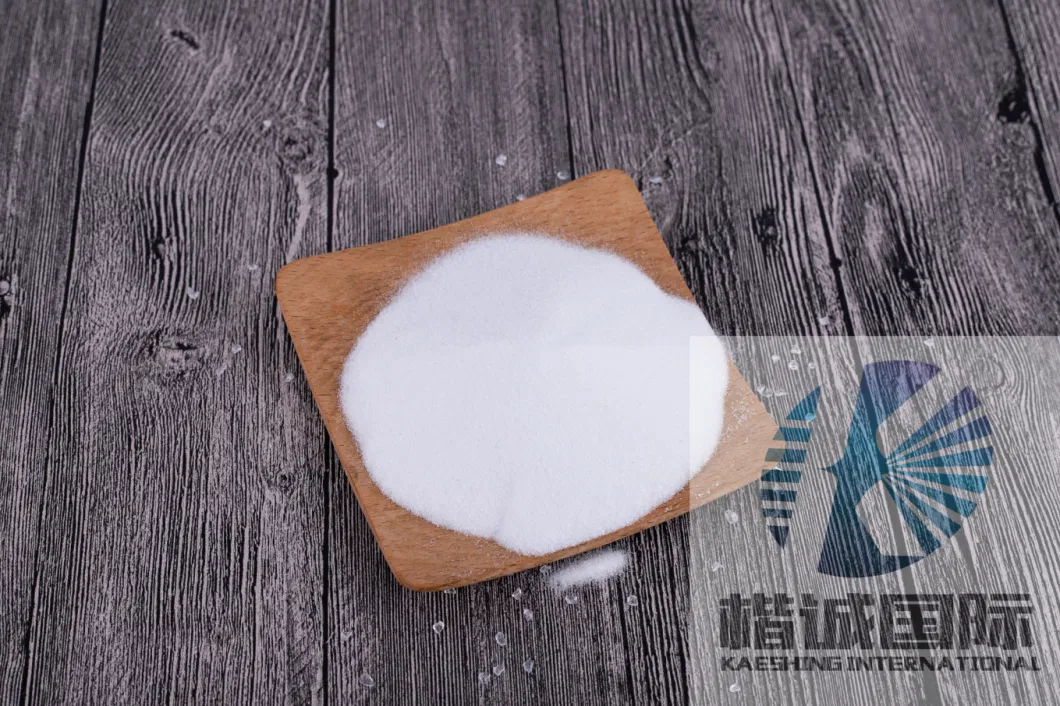

Fused Silica sand Appearance and Specifications:

1): It is forbidden to contain any unfused parts.

2): It is forbiden to have Foreign material, such as string, plastic line, carbon or wooden material, metal or other outside contaminants.

3): All color dots is forbidden except conditional black dots

4): It is not acceptable that black spot diameter is larger than 2mm.

5): Total black dots quantity should be less than 10 when opening the big bag equal or less than 10 dots per

square meters

3. Particle Size Distribution

*Pan designates the percentage of fused silica passing the last reported screen for each size.

Fused Silica sand Pictures:

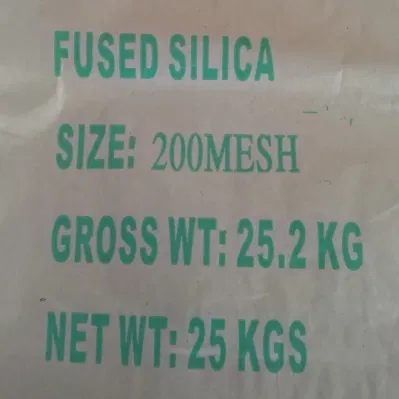

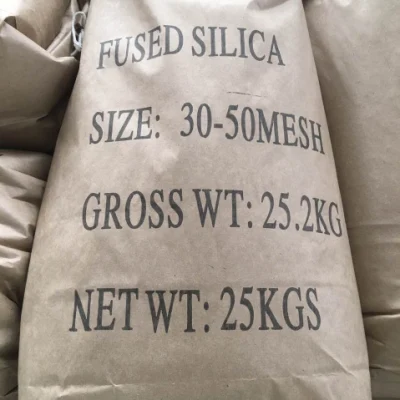

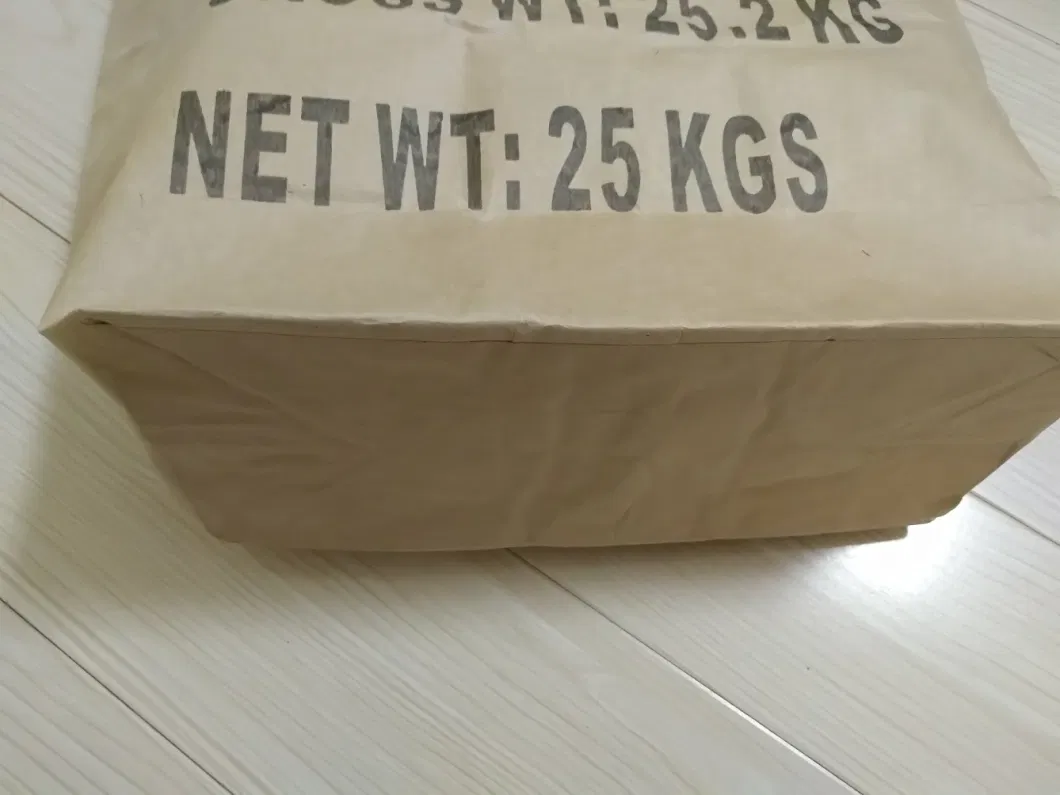

Fused silica powder Package and Delivery:

Paper bags

Plastic Woven Bag of 25kg Net each,Then on Pallet:

Factory and Quality Control Pictures:

FAQ:

Q1. Can I have a sample order for fused silica products?

A: Yes, we'd like to send samples free of charge by TNT/FEDEX/DHL. Mixed samples are acceptable.

Q2. What about the lead time?

A:It is 3-5 days for sending samples

It is usually within 15 days to delivery orders for quantity within 100mt,

Q3. Do you have any MOQ limit for fused silica sand order?

A: No.But the less the average cost higher.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 working days to arrive.

It depands on the distance by sea.7-40days.

Q5. How to process an order for fused silica powder Products?

A:

1).let us know your requirements or application.

2).We quote according to your requirements or our suggestions.

3).customer confirms the samples and pay deposit for formal order.

4).We arrange the production.

Q6. Is it OK to print my logo on packages?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

Q7: How to deal with the faulty?

A: Firstly, Our products are produced in strict quality control system and the defective rate will be less

than 0.2%.

Secondly,If it happened,we shall arrange to send new products to you and pay for all your lost.

Fused Silica sand XRD Report:

Fused Silica is made of high purity crystal silica from China Donghai-Xinyi by electrically fusing (fusing temperature 1800-2000ºC) to amorphous Silicon dioxide, then is specially engineered into lumps,cullet, ingots, sand,grain,granular and powder flour form designed for making PV fused silica crucible,thermal ceramic,refractory,EMC investment casting ceramic shell etc.

Fused Silica sand Appearance and Specifications:

1): It is forbidden to contain any unfused parts.

2): It is forbiden to have Foreign material, such as string, plastic line, carbon or wooden material, metal or other outside contaminants.

3): All color dots is forbidden except conditional black dots

4): It is not acceptable that black spot diameter is larger than 2mm.

5): Total black dots quantity should be less than 10 when opening the big bag equal or less than 10 dots per

square meters

| 1. | Physical Properties | ||

| 1.1 | Composition | SiO2 | |

| 1.2 | Structure | Amorphous | |

| 1.3 | Colour | Transparent or white | |

| 1.4 | Melting Temperature | approx.1750ºC | |

| 1.5 | Specific Gravity | 2.21g/cm3 | |

| 1.6 | Hardness | 7 Mohs | |

| 1.7 | Thermal Expansion | 0.5*10-6 | |

2. | Chemical Properties | ||

| 2.1 | SiO2 | >99.9% | |

| 2.2 | Al2O3 | <100ppm | |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | |||

| 2.3 | Fe2O3 | <30ppm for grains <60ppm for powder | |

| 2.4 | CaO | <15ppm | |

| 2.5 | Na2O | <15ppm | |

| 2.6 | K2O | <15ppm | |

3. Particle Size Distribution

| Standard | |||||||

| 10-20 | 30-50 | 50-100 | -120 | -200 | -325 | ||

| Mesh | Microns | ||||||

| +8 | 2360 | <2 | |||||

| +12 | 1700 | 6-25 | |||||

| +16 | 1180 | 33-50 | |||||

| +20 | 850 | 25-45 | <1 | ||||

| +30 | 600 | 13 | 25-40 | ||||

| +40 | 425 | 32-45 | |||||

| +50 | 300 | 15-30 | <13 | ||||

| +70 | 212 | 30-60 | |||||

| +80 | 180 | 0-11 | <1 | ||||

| +100 | 150 | 28-51 | <10 | <1 | |||

| +140 | 106 | 4-16 | 7-13 | <10 | |||

| +200 | 75 | <2 | 10-15 | <10 | <3 | ||

| +325 | 45 | 14-20 | 15-30 | 4-11 | |||

| Pan | <3 | <2 | <1 | 45-55 | 70-80 | 86-97 | |

Fused Silica sand Pictures:

Fused silica powder Package and Delivery:

Paper bags

Plastic Woven Bag of 25kg Net each,Then on Pallet:

Factory and Quality Control Pictures:

FAQ:

Q1. Can I have a sample order for fused silica products?

A: Yes, we'd like to send samples free of charge by TNT/FEDEX/DHL. Mixed samples are acceptable.

Q2. What about the lead time?

A:It is 3-5 days for sending samples

It is usually within 15 days to delivery orders for quantity within 100mt,

Q3. Do you have any MOQ limit for fused silica sand order?

A: No.But the less the average cost higher.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 working days to arrive.

It depands on the distance by sea.7-40days.

Q5. How to process an order for fused silica powder Products?

A:

1).let us know your requirements or application.

2).We quote according to your requirements or our suggestions.

3).customer confirms the samples and pay deposit for formal order.

4).We arrange the production.

Q6. Is it OK to print my logo on packages?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

Q7: How to deal with the faulty?

A: Firstly, Our products are produced in strict quality control system and the defective rate will be less

than 0.2%.

Secondly,If it happened,we shall arrange to send new products to you and pay for all your lost.