Basic Info.

Model NO.

S24

Surface Treatment

Sand Blast

Surface Roughness

Ra1.6

Standard

GB

Certification

CE, ISO 9001:2000, ISO 9001:2008

Name

5t/H Foundry Resin Sand Reclamation Line Small San

Sand Type

Furan Sand/Alkaline Phenolic Sand

Productivity

5 T/H, 10 T/H, 15 T/H, 20 T/H, 30 T/H, 50 T/H

Transport Package

Container

Specification

customized

Trademark

ANTAI / ATHI

Origin

China

HS Code

8474802000

Production Capacity

100 Sets/Year

Product Description

15 t/h foundry furan and phenol resin sand reclamation line for medium casting

The resin sand is a molding and core making technology which the mould and core sand will be self-harded in some time in the flask when added in certain amount glue.

At present, the foundry usually applies furan resin sand, ester-hardening alkaline phenolic resin sand and pep-set resin sand. The great characteristic is that under the room temperature the time during it's self-hard can be used. The self-harded rate and hardness is related to the room temperature, environment humidity. It's fit the single piece, small batch, various medium and large scale casting's mould and core, widely used in the, general, heavy, shipbuilding, locomotive, motorbike.

Resin sand reclaiming and molding systerm is of low energy consumption, less sand crushing, high regeneration efficiency, less wearing parts, easy maintenance, small occupied area and so on. This machine is a combination of regenerating and winnowing.And it has got the ISO9001:2008/CE/BV/TUV certification .

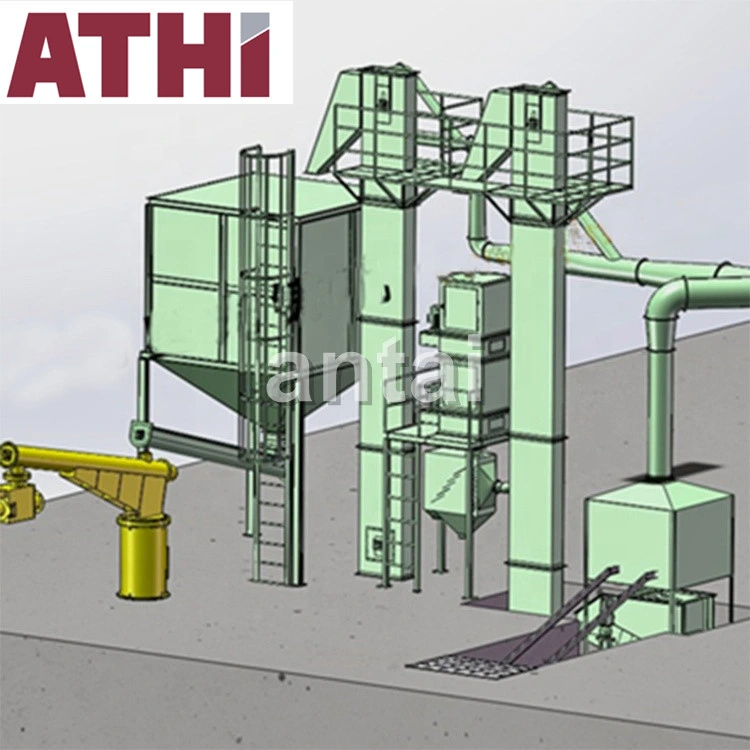

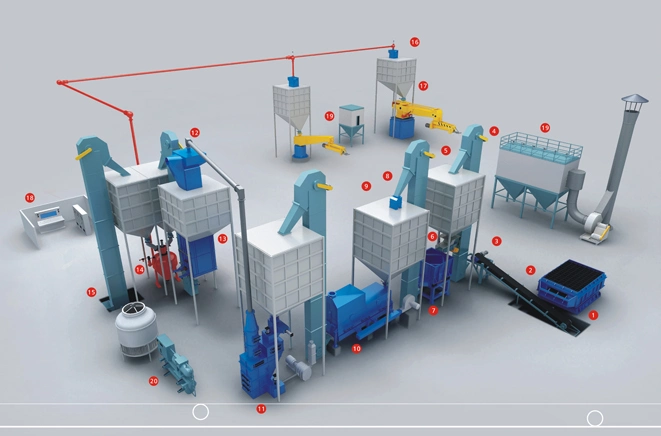

Components of resin sand reclaiming and molding system

shakout machine

vibrating conveyor

lifter

sand bin

vibrating feeder

vibrating crusher

magnetic separator

reclaimer

sand boilig and cooling bed

sand mixer

Features

1.Optimized secondary fuel consumption(LPG) depending on the properties of resin

2.Low Operating Cost

3.Fully automatic plant with instrumentation for process control

4.safe and reliable operation

5.smooth and consistent operation regardless of variations in resin content

6.Tailor made capacities available

model | S245 | S2410 | S2515 | S2520 | S2530 | S2540 | S2550 |

| productivity(t/h) | 5 | 10 | 15 | 20 | 30 | 40 | 50 |

Process Flow and Scheme Description of resin Sand Line:

According to the requirements of the demander and the factory floor plan provided by the demander, the supplier shall provide the demander with a reasonable sand treatment system scheme (see the design scheme diagram for details). The plan shall be used as the basis for design and acceptance of both parties after being signed and confirmed by representatives of both parties.

Resin sand mixer is suitable for casting steel, cast iron, non-ferrous alloy and other industries in the production of resin sand, sodium silicate sand and other types of self-hardening sand mixing. It can not only meet the requirement of single piece and small batch manual molding, but also can be used in coring machine, mechanized modeling and core-making production.

1) The adhesive supply system adopts a mechanical diaphragm pump and a gear pump , light in weight , compact in structure , stable in flow and reliable in flow rate .

2) Uniform mixing of sand can effectively guarantee the quality of molding (core-making) in production.

3) The sand mixing time is short , the amount of the head and tail sand is small , and the discharge is clean after stopping .

4) The sand - mixing cage arm of the fully open structure is convenient for the cleaning or adjustment of the sand mixing blade , and the operation and maintenance is convenient .

5) The mixed sand blade is made of tungsten carbide hard alloy with standard cast steel surfacing , ultra - wear resistance and wear resistance.

6)At the inlet of the sand mixer , the new and old sand proportion regulator can be configured according to the production requirements , so that the sand outlet quantity and the proportion of the new and old sand can be accurately controlled .

Technical Parameter

Item | Productivity (t/h) | Dia (mm) | Rotate speed (r/min) | Motor power (kw) | Turning radius (mm) |

S245 | 5 | Φ175 | 960 | 3 | R2000 |

S248 | 8 | Φ200 | 960 | 5.5 | R2000 |

S2412 | 12 | Φ225 | 720 | 7.5 | R2000 |

S2415 | 15 | Φ230 | 720 | 11 | R2000 |

S2420 | 200 | Φ250 | 720 | 15 | R2000 |