Basic Info.

Customized

Customized

Material

Stainless Steel

Application

Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Surface Roughness

Ra3.2

Service

One Stop Service. Machining-Assembly

Type

Customizable According to Customer

QC

Engineer and Inspector

Production Capaciy

200 Tons Per Month

Weight

0.1kg up to 50kg

Mold

Silica Sol Zircon Sand Mixed Slurry Production

Casting Surface Quality Level

2

Surface Preparation

Galvanized

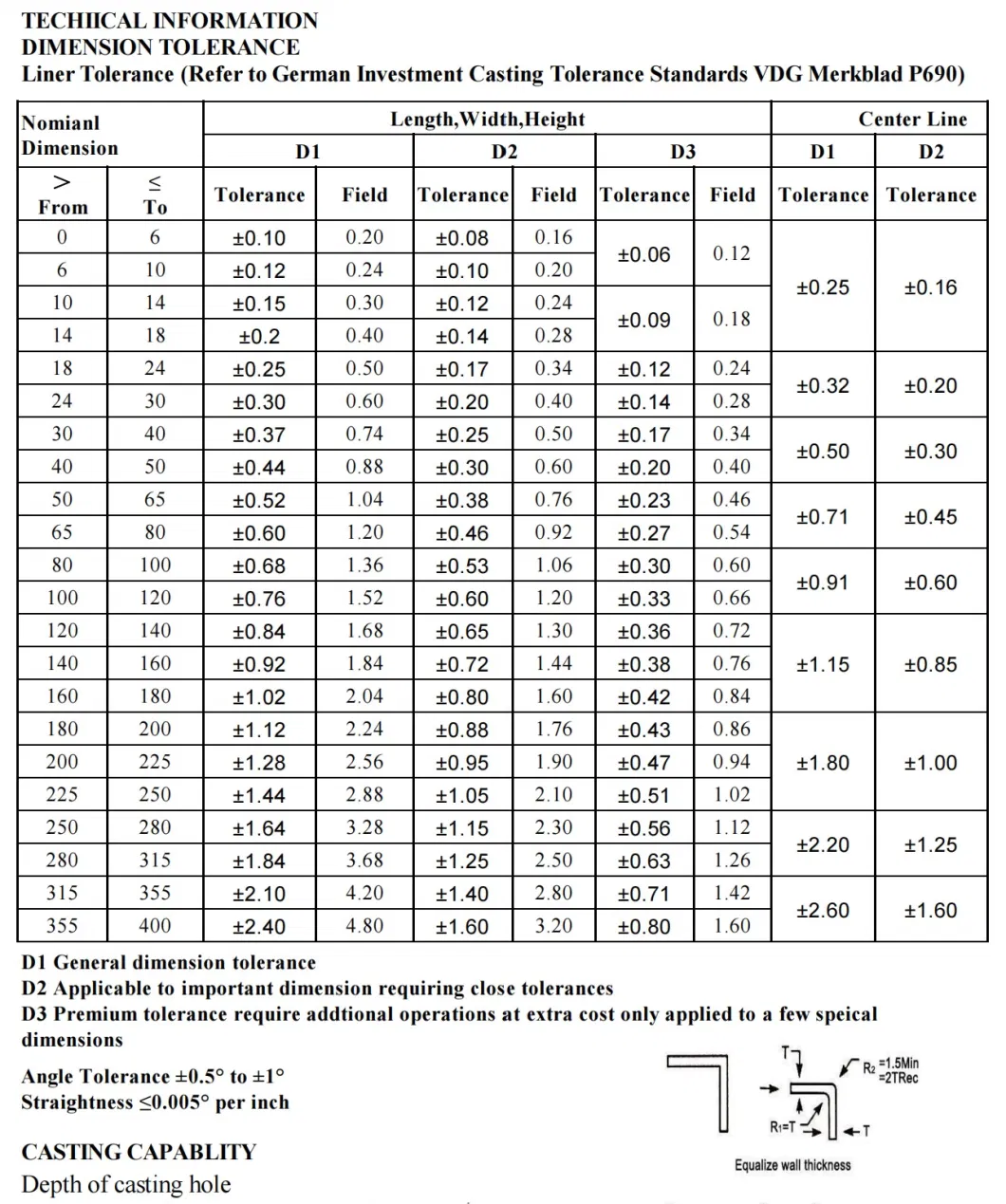

Machining Tolerance

Refer to German Investment Casting Tolerance Stand

Customized Support

Accept Customized

Quality Control

100% Inspection Before Packing

Lead Time

30-45 Days After Payment

CNC Machining

Accept Customized

Finish

De-Burr, Blasting, Polishing, Powder Coating

Transport Package

Bubble/Poly Bag+Carton Box

Specification

Stainless Steel(Customizable according to customer

Trademark

Lu Jin Wudang precision casting

Origin

China

Production Capacity

50000pieces/Year

Packaging & Delivery

Package Size

1400.00cm * 1400.00cm * 1400.00cm

Package Gross Weight

1000.000kg

Product Description

Product Description

| Material: | Carbon steel, alloy steel, stainless steel,Aluminum alloy, Copper, ect. |

| Process: | Lost wax casting + cnc machining |

| Casting dimension tolerance: | CT5-CT9 |

| Casting surface roughness: | Ra6.3 |

| Casting weight range: | 0.1-90 kg |

| Casting Size: | Max linear size: 1200 mm, Max diameter size: 600 mm |

| Machining tolerace | +/-0.03 |

| Machining surface roughness: | Ra0.8 ~ 6.3 um |

| Material standard: | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR |

| Surface treatment: | KTL (E-coating), Zinc plating, Mirror Polishing, Sand Blasting, Acid pickling, black oxide, Painting, Hot galvanizing,Powder coat |

| Quality control: | 100% inspection before packing |

| Application: | Train & railway, automobile& truck, construction machinery, forklift, agricultural machinery, marine parts, petroleum machinery, construction, valve and pumps, electric machine, hardware, power equipment and so on. |

| Keywords: | Investment casting, sand casting, precision casting, lost wax casting, water glass casting, silica sol casting, die casting, iron casting, steel casting, ductile iron casting |

Our Advantage:

Water glass method dewaxes into the high-temperature water, and the ceramic mold is made of water glass quartz sand. Silica sol method dewaxes into the flash fire, and silica sol zircon sand makes the ceramic mold.

The silica sol investment casting can get a better surface roughness Ra3.2.

Company Introduction

Shiyan Wudang Mountain Tourism Economic Zone Lu Jin Investment Co., Ltd. is located in Wudang Mountain Tourism Economic Zone, a famous Taoist shrine in China, with convenient land and water transportation. The company was established on December 31st, 2001, and passed the 3C ISO9001:2000 quality system certification and compulsory certification. The company has 200 employees, including 30 management and engineering technicians. The fixed assets are about 10 million yuan, covering an area of 6,480 square meters and a building area of 3,200 square meters. Annual design production capacity: 1,800 tons.

Shiyan Wudang Mountain Tourism Economic Zone Lu Jin Investment Co., Ltd. is located in Wudang Mountain Tourism Economic Zone, a famous Taoist shrine in China, with convenient land and water transportation. The company was established on December 31st, 2001, and passed the 3C ISO9001:2000 quality system certification and compulsory certification. The company has 200 employees, including 30 management and engineering technicians. The fixed assets are about 10 million yuan, covering an area of 6,480 square meters and a building area of 3,200 square meters. Annual design production capacity: 1,800 tons. Existing: carbon steel (2G270-510, 2G310-570), stainless steel (304, 316, CF8, CF8M), mainly involved in automobile, chemical industry, electric power, machinery and precision casting products.

Why Choose Us

Tolerances For Investment Casting

FAQ

Q1:How long is the product warranty period?

A: One years.

Q2: How to distribute the product?

A: We generally provide FOB prices, and the freight is borne by the buyer. If the buyer has the demand, we can also provide CIF price, our company is responsible for shipping products.

Q3: Return policy?

A: In case of any problem with the product, the two parties shall negotiate a return or exchange according to the terms and conditions of the contract.

Q4:After-sales problems?

A: If there is a quality problem during the warranty period, our company will answer it to the customer within 24 hours. If the problem is more serious, our company will arrive at the customer site within a week to answer it. Products beyond the warranty period we provide maintenance services, provide paid replacement parts, provide paid customer on-site service.

Q5: What size products can you produce?

A: We can produce products of various sizes for different industries, weighing anywhere from a few ounces to as much as 250 pounds.

Q6:: What surface finish can be produced?

A: Ra3.2, and the machining finish can reach about Ra0.4. Other surface treatments can be done from electrophoresis, blackening, polishing, galvanizing to chrome plating, etc.

Q7: How to get sample?

A: Sample is acceptable. Please tell us what product you need.

Q8: What's your payment policy?

A: For the sample order, our payment policy is 100% T/T payment (Telegraphic transfer payment) in advance or other payment method. For the bulk order, our payment policy is 30% T/T in advance, 70% balance should be paid 7 working days before delivery.

Q9: How long is your delivery time?

A: It depends on product quantity and specific requirements. Usually sample needs 7-10 days, mass order needs 20-50 days.

Q10: What materials can you cast?

A: We work with a variety of materials, including stainless steel, carbon steel, aluminum alloys, copper alloys, nickel-based alloys, and more. We can assist in material selection based on your specific requirements.

Certificate