Basic Info.

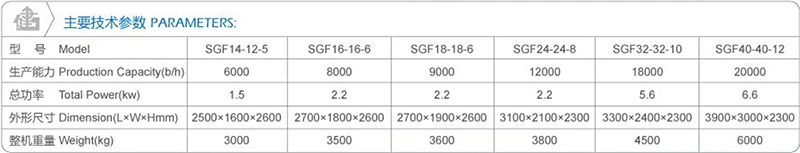

Model NO.

JH 80-80-20

Feed Cylinder Structure

Multi-Room Feeding

Dosing Device

Capacity Cup

Filling Principle

Pressure

Packaging Container Lifting Structure

Pneumatic Lifting

Structure

Rotary

Packaging

Bottle

Packaging Material

Composite Materials

Transport Package

PE Wrapping Film, Simple Wood Packaging

Specification

10000*1800*2600

Trademark

JianWang

Origin

Jiangsu, China

HS Code

8422301090

Production Capacity

10000 Bottles Per Hour (500ml)

Product Description

This machine can produce PET bottle which can resist high temperature, such like 92 centigrade degree. This has solved the problem of the traditional juice and other liquid food packing.

CM-8Y heat-resistant semi-automatic bottle blow molding machine is suitable for producing any shape of PET containers and volume is from 10-2000ml. It is widely used to produce mineral water bottles, carbonated beverage bottles, cosmetic bottles oil bottles etc.

Adopting double crank connecting bar clamping and clamping mould is stable and fast, Adopt for infra-red rotary oven and heated equally.

The air system has been divided into two parts: Pneumatic action part and bottle blow part to meet the different requirements for the pressure of action and blow. It can provide sufficient and steady high Pressure for blowing large irregular shaped bottles.

The machine is also equipped with muffler and different parts of refueling system.

The machine can be operated in the step-by-step mode and the semi-auto mode.

The machine is small with low investment, It's easy and safe to be operated by one person.

It is easy to change the packaging combination and bottle type to integrate the multi-function.

Company Profile:

Zhangjiagang Jianwang Food Packaging Machinery Co., Ltd., formerly known as Zhangjiagang Food Packaging Machinery Factory, is a professional manufacturer engaged in the research, development and production of food packaging machinery. Relying on strong technical force and taking product development as the guide, the company produces more than 20 kinds of products of different types, which are sold well in more than 20 cities and autonomous regions across the country, and exported to Southeast Asia, Singapore, Russia and other countries and regions.

The company was established in 1978 and began to produce beverage machinery products and meat processing machinery production lines. In 1994, it opened up a production line for negative pressure filling machines. In 1996, it obtained the production license for measuring instruments and passed the measurement qualification. It was confirmed that in 1998, LRGF automatic production was put into production; DGZ series of three-in-one, four-in-one PET bottle cold and hot filling production lines for medium bottle, filling and capping; Three-in-one isobaric pressure for medium bottle, filling and capping Filling line. Production of DGJ series high-precision quantitative filling machine, QTGF series 3-5 gallon barrel production line, OP-320 large row slicer, DZJ series: Medium bottle, filling and capping three-in-one isobaric filling production line, ZGJ Series-1050 dicing machine, etc., are all manufactured by digesting and absorbing advanced technologies from Germany, Italy and Japan. They are at the international advanced level in the 1990s and have obtained a number of national patents. The products are constantly being improved in practice. We can provide more perfect packaging for your high-quality products.

FAQ: