- Overview

- Company Profile

- Workshop

- Product Description

- Our Advantages

- Certifications

- Quality Control

- Packaging & Shipping

- FAQ

Basic Info.

Product Description

Qingdao Chengenxin Industry and Trade Co., Ltd. is a comprehensive enterprise integrating

metal die-casting production, aluminum alloy high-strength squeeze casting, plastic injection

production, and mold R&D and manufacturing.

Focus on the development of technical services for lightweight equipment, processes and products.

We have successfully provided a complete set of solutions in light alloy precision forming for hundreds

of domestic and oversea customers, helping customers solve many production technical problems and

achieve value increasement, the industries include automobiles and motorcycles, communications,

engineering machinery,aviation, and electronics etc.

Our Equipment

Our Equipment

-injection molding equipment

-Precision CNC lathes

-Milling machines

-Ultrasonic welding machines

-Avarious auxiliary processing machinery.

Product parameter

Product parameter

| Process | Aluminum Die casting, Squeeze casting+T6, Zinc Alloy die casting,CNC machining, Turning |

| Equipment | Cold chamber die casting machine:200T/280T/400T/600T/800T/1100T.CNC centers, CNC turning, CNC lathes, electrical pulse, line cutting, milling, drilling, grinding |

| Material | A319, A356, A360, A369, A380, A383, A384, A413, A535, 44300, 44300, 46000, AlSi9Mg, AlSi9Cu3, ADC12, ZL102, ZL104, ZL108, Zamak2,3,5,7 ect. Squeeze Casting: A356+T6, A356.2+T6, AlSi9Mg+T6, Zl108+T6, AlTi-Alloy+T6 |

| Surface | Trimming, Deburring,Polishing, Shot blasting, Sand blasting,Tumbling, Powder coating, Anodizing, Chrome, Zinc, Electrophoresis, Passivation, Chemical coating. |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD/CATIA |

| Products Application | Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect. |

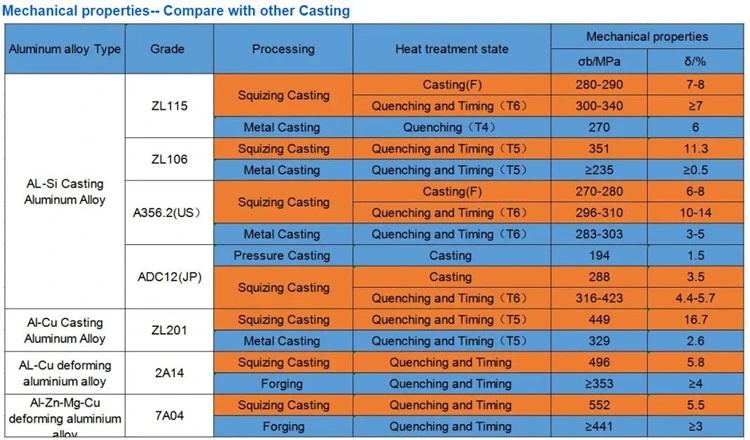

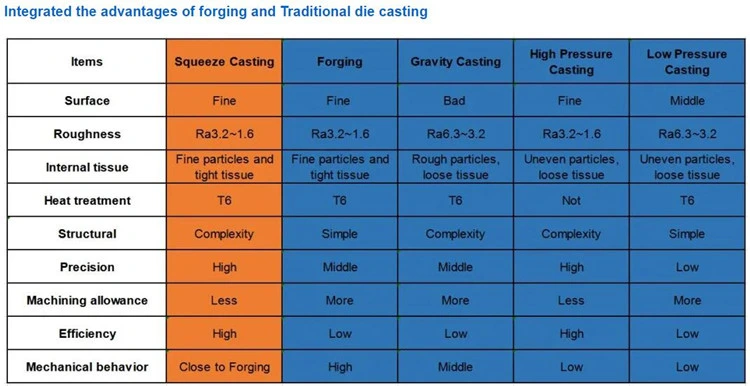

Our New Porcessing Technology -Squeeze Casting

or semi-molten metal or alloy in the mold cavity, and then apply high pressure to plastically deform

the solidified metal. The unsolidified metal is subjected to isostatic pressure and high-pressure

solidification occurs at the same time then get the parts or blanks, T6 heat treatment can be performed

to obtain high-strength, high-precision parts.

1. How can I get the quotation?

Please send us information for quote: drawing, material, weight, quantity and request.

2. If we don't have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

3. When can I get the sample?

Sample: 15-20days after you start to make mold. The accurate time depends on your product.

4. What is your main order time?

Order time:20-25 days after the payment. The accurate time depends on your product.

5. What is your payment method?

Tooling: 100% TT advanced.

Main order: 50% deposit, balance 50% to be paid before shipment.

6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, MAX..