Basic Info.

Model NO.

Brown Fused Alumina

Function

Blasting Media, Abrasive Material

Source

Artificial Abrasives

Particle Size

14#-220#

Hardness

9.0

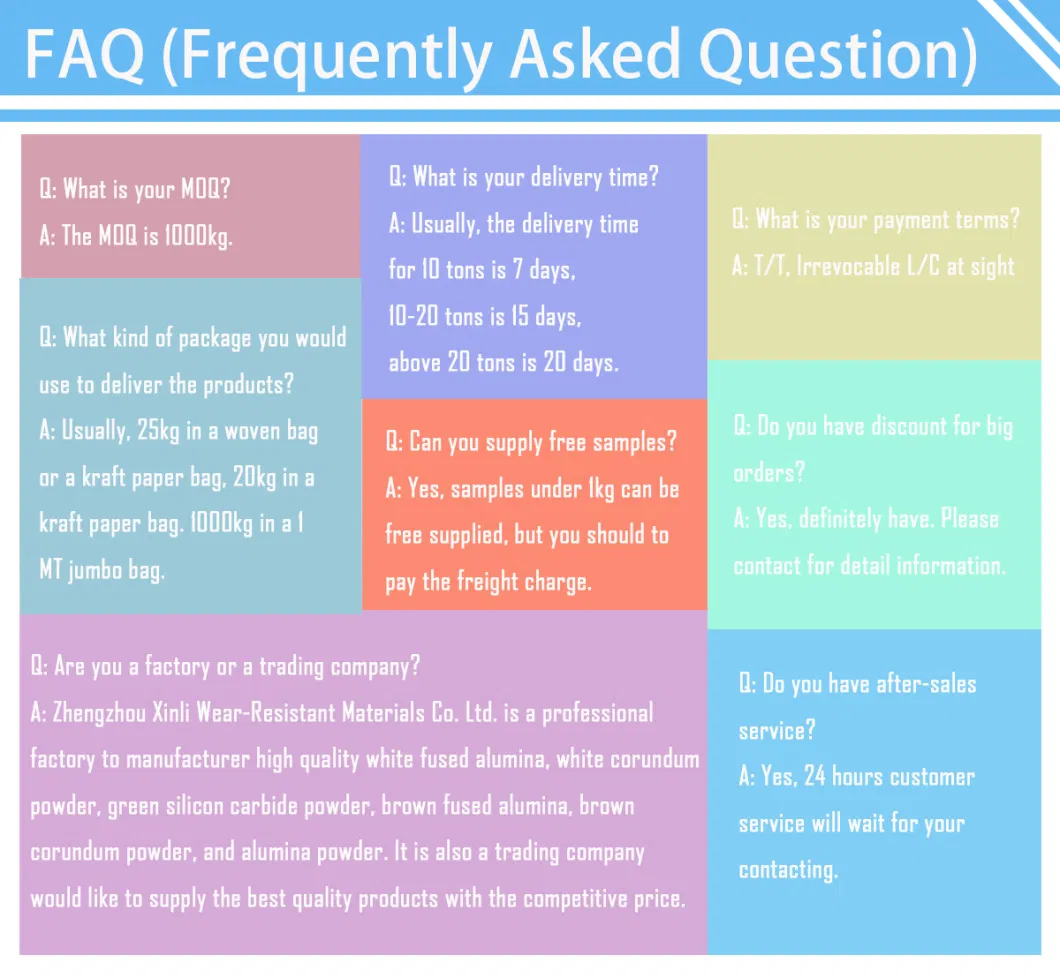

MOQ

1 Ton

Free Sample

Sample Provided

Appearance

Grit

Raw Material

Bauxite

Color

Brown

Melting Point

2250ºC

The Maximum Temperature

1900ºC

Specific Gravity

3.95

Bulk Density

1.53-1.99c/Cm3

Real Density

≥3.90c/Cm3

Transport Package

Ship

Specification

95.00%-97.00%

Trademark

XINLI

Origin

China

HS Code

2818101000

Production Capacity

2000 Ton/Tons Per Month

Packaging & Delivery

Package Size

20.00cm * 20.00cm * 20.00cm

Package Gross Weight

25.000kg

Product Description

Brown Fused Alumina

Brown fused alumina is made of high-quality bauxite as raw material, anthracite and iron filings. It is made by arc smelting at 2000°C or higher temperature. It is crushed and plasticized by self-grinding machine, magnetically selected to remove iron, sieved into various sizes, and its texture is dense and hard. High, spherical pellets, suitable for the production of ceramic, high-resistance abrasive resin and grinding, polishing, sandblasting, precision casting, etc., can also be used to manufacture high-grade refractories.

The brown corundum abrasive has the characteristics of high purity, good crystallization, strong fluidity, low coefficient of linear expansion, and corrosion resistance. The practice of dozens of fire-proof production companies has verified that this product has the characteristics of no explosion, no chalking, and no cracking in the application process. In particular, it is much higher than the cost-effectiveness of traditional brown corundum, making it the best aggregate and filler for fused alumina refractories.

| Chemical and Physical Features | ||||||

| Items | Al2O3 | Fe2O3 | SiO2 | Bulk density | Color | Application |

| Grade I | ≥95 | ≤0.3 | ≤1.5 | 3.85 | Maroon | Refractory material, |

| Grade II | ≥95 | ≤0.3 | ≤1.5 | 3.85 | Black particle | fine polishing |

| Grade III | ≥95 | ≤0.3 | ≤1.5 | 3.85 | Gray powder | Polishing, grinding |

| Grade IV | ≥95 | ≤0.3 | ≤1.5 | 3.85 | Black particle | Grinding, cutting, sandblasting |

| Grade V | ≥95 | ≤0.3 | ≤1.5 | 3.85 | Gray powder | Polishing, grinding |

Zhengzhou Xinli Wear-resistant Materials Co. Ltd.

Founded in 1996, Zhengzhou Xinli Wear-resistant Materials Co. Ltd. Is a professional integrative enterprise specializing in R&D, producing, and selling various wear-resistant materials, such as white corundum powder, alumina powder, green silicon carbide powder, brown corundum powder, etc. Xinli Wear-resistant Materials has completed inspection equipment and quality control system, and obtained ISO9001:2015 quality management system certification.