- Overview

- Product Description

- Company Introduction

- Packaging & Shipping

- FAQ

Basic Info.

Packaging & Delivery

Product Description

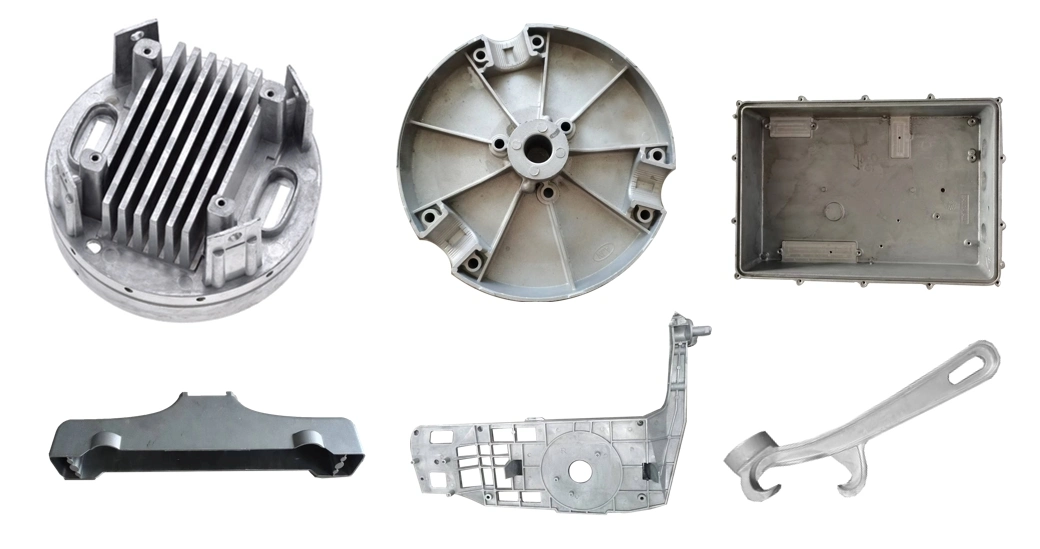

Qingdao ACES is a professional OEM manufacturer with extensive experience for high pressure die casting, liquid die forging casting, CNC machining and surface treatment, especially for high strict tolerance and surface treatment requests.

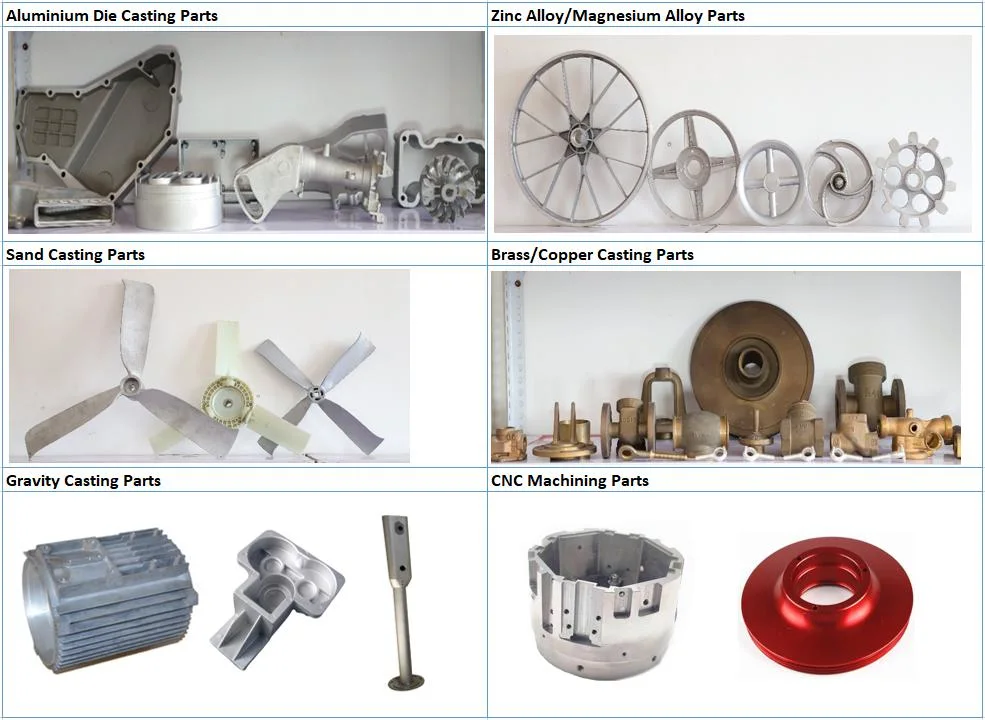

| Item | Specification |

| Material | ADC10,ADC12,ADC14,A356,A360,A380, ZAMAK3#,ZAMAK5#,ZAMAK8#, Magnesium alloy AZ91D, AM60B, Brass,Copper and others as customer request |

| Process | gravity casting, sand casting,die casting. |

| Die Casting Machine | 180tons to 900tons and 1200tons |

| Surface treatment | polished,wet painting,powder coating,e-coating,electro-plating;PVDF coating;anodizing,chemical blacken; |

| Machining process | turning,milling,drilling,boring,grinding,reaming,honing etc. |

| Inpection | CMM inspection, gauge inspection,hydro or air pressure test, NDT test; We also can customize the inspection tools acoording to the part demands. |

| Mould life | 200000pcs |

Qingdao ACES is an OEM manufacturer, mainly for casting parts, CNC machining parts and sheet metal stamping parts. We have wide experience in producing and exporting metal parts, not only for OEM parts but also have the professional team for ODM.

Besides the casting, ACES also provides the customers with more comprehensive services. Various machining equipment will meet different precision machining requests, such as NC lathe, CNC precision automatic lathe, vertical CNC machine, horizontal CNC machine center, CNC engraving machine, 4-axis and 5-axis CNC machine center. From the sample developing to the mass production, the quality is strictly controlled from each operator to the professional inspection team. The quality control tools such as CMM inspection, flow chart, control plan, PPAP and CPK analysis are also widely used in our workshop.

ACES will offer you one-stop metal manufacturing OEM service from raw castings to machining, stamping including various surface treatment. Welcome to contact us if you have any concerning demands.

ACES will design the suitable package for each part during sample development according to the part structure, qty per lot and customers requirement.

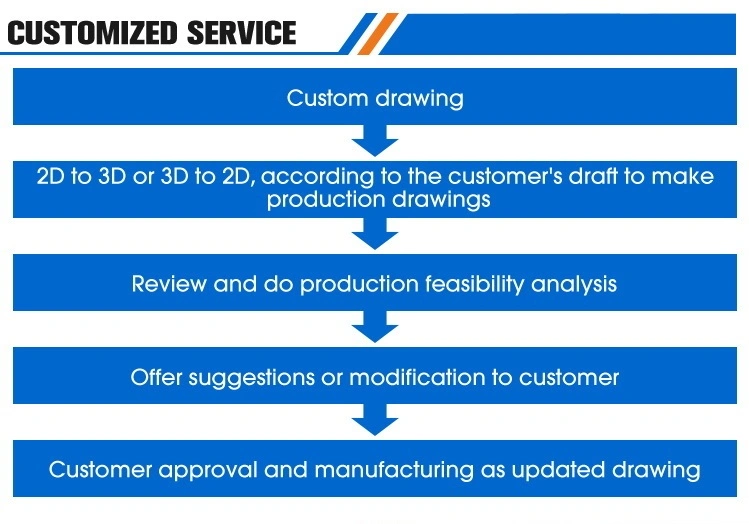

Q1: How to get the quotation?

A1: For quotation we need the customer to offer the 2D and 3D drawings, usage information, material request, surface treatment and other technicial which need to pay attention and other information which will affect the quotation.

A2: Normally it will need 1 to 5 days.

Q3: Can you produce the parts according to the samples?

A3: Yes, we have the reverse engineering capability.