Basic Info.

Model NO.

jiahao xinda

Material

Aluminum

Application

Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Casting Machinery

Sample

Available

Pay

T/T, L/C, Paypal, Western Union.

MOQ

1PCS

Tolerance

+-0.01

Logo Service

Support

Transport Package

PP Bag, Carton, Wood Box or Customized

Specification

customized

Trademark

customized

Origin

China

HS Code

847990909

Production Capacity

100000PCS/Month

Product Description

| Product Description |

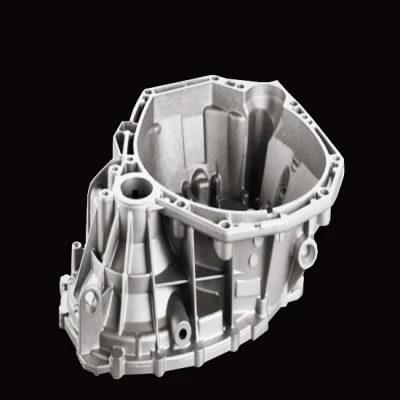

OEM Customized High End Car Motorcycle Spare Auto Metal Part by 3D Printing Sand Mold Casting Gravity Low Pressure Casting & Rapid Prototyping CNC Machining

| Certificate | ISO9001:2015 |

| Service | CNC Machining Turning and Milling Laser Cutting Plastic Injection Moulding Stamping Die Casting 3D Scanning Service OEM Parts |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075, 5051 etc 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc 3). Steel: 4140, Q235, Q345B,20#,45# etc. 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc 6). Copper, bronze, Magnesium alloy, 7). Plastic:Delrin, POM,Acrylic, PC, ABS, PE,etc. |

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, Power coating, Passivation PVD, Titanium Plating,Electrogalvanizing, electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), Electro Polishing,Chrome Plating, Knurl,Laser etch Logo, etc. |

| MOQ | 1PCS For Sample |

| Tolerance&Surface Roughness | +/-0.005 - 0.1mm & Ra0.2 - Ra3.2 (Customize available) |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| QC | 100% inspection, ROHS |

| Product Show |

| Company Profile |

| Shenzhen Jiahao Xinda Technology Co., Ltd. established in 2009, is a pure-play enterprise dedicated to developing and manufacturing nonstandard machine parts and equipment processing, covering an area of 2600 square meters. Our company is located in Fuyong Town, Bao'an District, Shenzhen City. We have over 40 professional manufacturing and possessing equipment, which includes CNC, milling machine, lathe machine, precision grinding machine and line cutting machine. And there are various testing equipment imported with high precision in our quality department, including 3D and 2.5D measuring equipment,altimeter and hardness tester. At present, our knock-out products mainly include precision automatic equipment parts, tooling fixtures,mobile phone accessories, automotive parts, medical equipment parts,aerospace, solar and electronic equipment, photoelectric communication, office automation, industrial equipment, laser equipment, household appliances, highways,and other industries. |

| Workshop |

| Certification |

| Exhibition |

| Packing& Shipping |

| FAQ |

1. What's your main business?

We are specialized in CNC machining. We are able to manufacture non-standard parts according to drawings or samples.

We are specialized in CNC machining. We are able to manufacture non-standard parts according to drawings or samples.

2. How can I get the quotation?

Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.)or samples. Then we will quote the best price within 24h.

3. Do you provide sample? It's free or extra?

Sure, Our sample is provided after receiving the tooling cost and courier fees.

4. What if the parts are not good?

As a matter of fact, we wont take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until

your satisfaction.

5. What's the average delivery data?

Generally it is 10-15 days , it is according to quantity.

6. What kind of payment terms do you accept?

T/T, L/C, Escrow, paypal, western union, moneygram etc.

7. Is it possible to know how is my product going on without visiting your company?

We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining

progress.

8. Can you customize products for your customers?

Yes, Customized service is one of our core business, we have no small MOQ request.

3. Do you provide sample? It's free or extra?

Sure, Our sample is provided after receiving the tooling cost and courier fees.

4. What if the parts are not good?

As a matter of fact, we wont take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until

your satisfaction.

5. What's the average delivery data?

Generally it is 10-15 days , it is according to quantity.

6. What kind of payment terms do you accept?

T/T, L/C, Escrow, paypal, western union, moneygram etc.

7. Is it possible to know how is my product going on without visiting your company?

We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining

progress.

8. Can you customize products for your customers?

Yes, Customized service is one of our core business, we have no small MOQ request.