Basic Info.

Model NO.

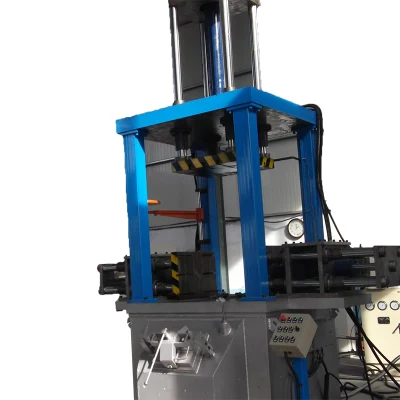

Molding Machine

Computerized

Computerized

Certification

CE, ISO9001:2008, GMP, QS

Product Name

Molding Machine

Transport Package

Plywood

Specification

Standard specification

Trademark

semc

Origin

China

HS Code

8456909000

Production Capacity

10000set/Year

Product Description

Product description

This machine can be used for molding clay sand upper and lower boxes in various casting workshops. It can be used by a single machine or a mechanized assembly line or a semi-automatic line.

The main features of this machine are as follows:

1. Pneumatic multi contact compaction is adopted, without the trouble of oil leakage; the specific pressure is moderate, without special requirements for molding sand, and the number of contacts is large, which is suitable for complex model modeling.

2. When the machine is compacted, the frame is not stressed, but four pull rods hang down from the side of the multi contact body to hook the working table. With the downward extension of the multi contact, compaction is carried out. If the contact, hook, sand box, shaped plate and working table are regarded as a system, this kind of compaction strength is internal force or internal force compaction.

3. The contact is compacted by sand mold on the one hand and vibrated together with the workbench (separated from the rack, the rack will not be vibrated). Therefore, the impact compaction effect is good, the hardness of sand mold is high and even (the average hardness is 85-90, the hardness of B-type hardness tester), the sand consumption can be as small as 20-30mm, the sand consumption ratio can reach H: B = 2-3, and the hardness of vertical surface of mold cavity can still reach more than 80.

The machine adopts spring full buffer pneumatic micro vibration mechanism, so there is no special requirement for the foundation, and the connecting rod is used for formwork lifting.

Synchronous shaft structure, air pressure oil speed regulation, good mold starting synchronicity, and free speed control.

Resin sand regeneration, molding line and chromite sand separator

This machine can be used for molding clay sand upper and lower boxes in various casting workshops. It can be used by a single machine or a mechanized assembly line or a semi-automatic line.

The main features of this machine are as follows:

1. Pneumatic multi contact compaction is adopted, without the trouble of oil leakage; the specific pressure is moderate, without special requirements for molding sand, and the number of contacts is large, which is suitable for complex model modeling.

2. When the machine is compacted, the frame is not stressed, but four pull rods hang down from the side of the multi contact body to hook the working table. With the downward extension of the multi contact, compaction is carried out. If the contact, hook, sand box, shaped plate and working table are regarded as a system, this kind of compaction strength is internal force or internal force compaction.

3. The contact is compacted by sand mold on the one hand and vibrated together with the workbench (separated from the rack, the rack will not be vibrated). Therefore, the impact compaction effect is good, the hardness of sand mold is high and even (the average hardness is 85-90, the hardness of B-type hardness tester), the sand consumption can be as small as 20-30mm, the sand consumption ratio can reach H: B = 2-3, and the hardness of vertical surface of mold cavity can still reach more than 80.

The machine adopts spring full buffer pneumatic micro vibration mechanism, so there is no special requirement for the foundation, and the connecting rod is used for formwork lifting.

Synchronous shaft structure, air pressure oil speed regulation, good mold starting synchronicity, and free speed control.

| Product Name | Mechanical sand moulding machine for foundry |

| Sand box size | 1520×1220(1320)×190mm |

| Maximum dimension of sand box | 2100 × 1320 × 190mm |

| Worktop size | 1980 × 1030mm |

| Normal working air pressure | ≥ 0.55mpa |

| Number of multiple contacts | 60 |

| Contact compaction stroke | 250mm |

| Stroke of mould cylinder | 350mm |

| Diameter of mould cylinder | Ф 160 × 2 |

| # | Equipment | Type | Parameter | QTY | Power(KW) |

| B01 | Shakeout and crushing machine | LPZ10 | The table is 2500x2000mm. German owned Baofei Uster vibrating motor, maximum load 10T, 8.5KWx2 | 1 | 17.0 |

| B02 | Magnetic separator | S528II | Width=300mm,magnetic field intensity2100GS | 1 | 0.4 |

| B03 | Chain Hoist | NE30 | Height=17.5m, conveying capacity: 35m3/h,Volume of bucket: 10L,pitch of buckets: 0.6m | 1 | 11.0 |

| B04 | Regeneration machine | S528IVA | Vortex current regeneration,Secondary regeneration, centrifugal impact film removal | 2 | 44.0 |

| B05 | Friction regeneration machine | Capacity: 10T/h | 1 | 48.0 | |

| B06 | Bucket elevator | S528VII | Width=350,Height=12.5m,High strength tape | 1 | 5.5 |

| B07 | Vertical air separator ash remover | 1 | 0.0 | ||

| B08 | Bucket elevator | S528VII | Width=350,Height=13.8m,High strength tape | 1 | 5.5 |

| B09 | Sand temperature modulator | S528VIA | The sand temperature can be preset in the PC according to the process, the seamless pipe type water-cooling pipe and the water pump. | 1 | 5.0 |

| B10 | Bucket elevator | S528VII | Width=350,Height=13.8m,High strength tape | 1 | 5.5 |

| B11 | Air control single gate valve | TYM1 | Cylinder controlled sand flow rate | 10 | 0 |

| B12 | Pneumatic transmission | Y918 | Transmitter 0.8m3, 2 unloading points, supercharger, etc. | 2 | 0 |

| B13 | Bucket elevator | S528VII | Width=250,Height=12.4m,High strength tape | 1 | 4.0 |

| B14 | Pneumatic transport (transmission of chromium ore) | Y915 | transmitter 0.5m3, 2 sets of discharge points respectively discharge, supercharger. | 1 | 0.0 |

| B15 | Pneumatic conveying (sending old sand) | Y918 | transmitter 0.5m3, 2 sets of discharge points respectively discharge, supercharger. | 1 | 0.0 |

| B16 | SZ2512L fixed sand mixer | 10T/H | Capacity: 10T. Radius of rotation: 3000 mm, radius of rotation of small arm 1800 mm, height of sand outlet 1600mm, liquid bucket, resin pump, electronic control, etc. For core making. | 1 | 21.5 |

| B17 | Vibrating Table | Z292 | vibrating table 1200x2500mm, load 2t. Core making. | 1 | 3.0 |

| B18 | S2530B fixed sand mixer | 30T/H | Capacity: 30T. Radius of rotation: 4000 mm, radius of rotation of small arm 2050 mm, height of sand outlet 1600mm, liquid bucket, resin pump, electronic control, etc. | 1 | 45.6 |

| B19 | Vibrating Table | Z2920 | Table: 3800x3800mm,load: 20 t. | 1 | 13.0 |

| B20 | Dust collector | MC80 | For dust collecting of pneumatic transmission part | 2 | 15.0 |

| B21 | Pulse back-blowing bag-type dust collector | FD630 | For dust collecting of sand shakeout;Filter area 486 square meters, air volume: 55000m3/h. | 1 | 0.0 |

| B22 | Fan | Muffler, damping pad, etc. 4-72NO12C,75 Kw | 1 | 75.0 | |

| B23 | Scrap iron hoisting system | It is composed of 1t electric hoist, guide rail, bracket, etc. | 1 | 3.0 | |

| B24 | level-sensing device | C18 | Check whether the material is present or not. | 20 | 0.0 |

| B25 | Pneumatic control system | It is composed of air control box, triplet, solenoid valve, ball valve, pipe joint, etc. | 10 | 0.0 | |

| B26 | PLC system | PLC integrated block Omron, the main electrical components are domestic famous brand, electric cabinet, hand control table, switch, analog screen, etc. | 1 | 0.0 | |

| F01 | Non-standard steel structure | Sand bank, platform, cover plate, dust-removing air pipe, pneumatic conveying pipeline, etc., and the buyer is provided with. | 0 | 0.0 | |

| Subtotal | 332.0 | ||||

| Chromite sand separation equipment | |||||

| C01 | Chrome ore separator | Productivity 10T/h, selection rate ≥ 75%, imported equipment | 1 | 10 | |

| Total |