Basic Info.

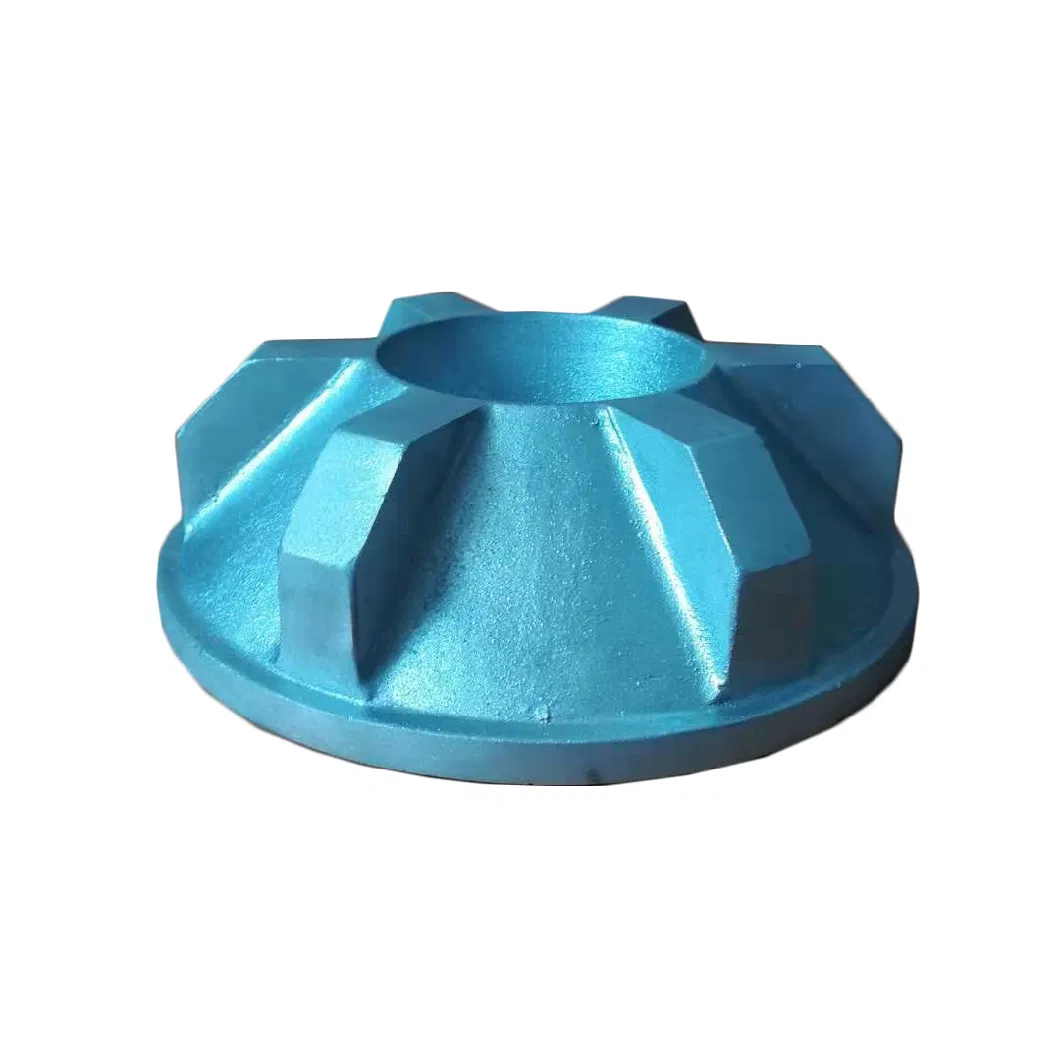

Product Description

Description:

| NO. | ITEM | DESCRIPTION |

| 1 | Material | Aluminum Alloy: A380, A360 A356 |

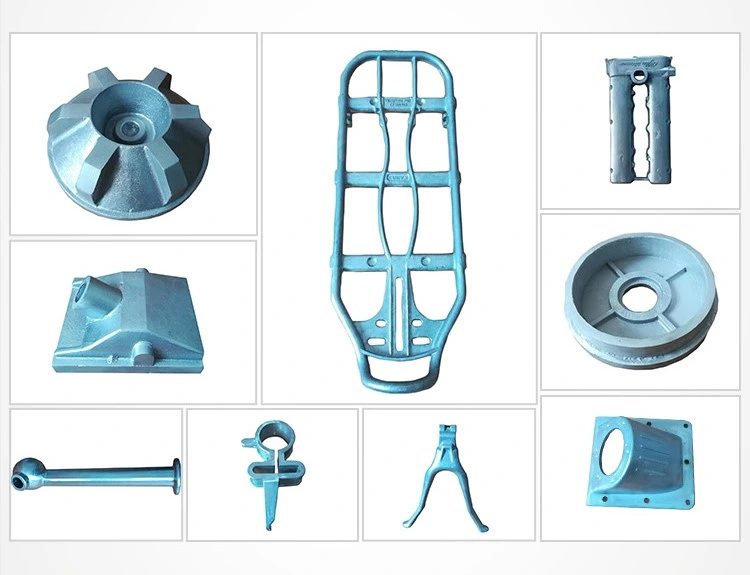

| 2 | Process | Aluminum Casting, CNC Machining Process, Assembling and Packing |

| 3 | Finish | Powder Coating, Anodized, Oil Painting, Sandblasting etc. |

| 4 | Tolerance | (+/-) 0.1mm |

| 5 | Packing | Wooden box, or as per the customer's requirements |

| 6 | Dimension | Based on sample or drawing from the clients |

| 7 | Equipment | Sand core machine, Casting machine, CNC machining center, grinding machine, milling machine, drilling machine, , chamfering machine, CNC cutting machine etc. |

| 8 | QC Tools | Hardness tester, precision plug gague, gauge block, digital outside micrometer, outside micrometer, digital caliper, inside micrometer, inside dial indicator, dial vernier caliper, dial indicator, depth vernier caliper and so on |

| 9 | Precision/Tolerance | Achieve +/- 0.1mm tolerances for Die casting and gravity casting Meet +/- 0.005mm tolerances for cnc machining |

| 10 | Business scope | Gravity Casting, Die Casting, Machining, Assemling as one-stop solution |

| 11 | Application | Auto Parts, Fire Fighting Equipment, Bicycle Parts, Automobile, Electric appliance, and other industries |

Advantage:

1. Standard Aluminum Ingot to make sure good raw material.

2. Experienced Casting Master to make sure good quality casting.

3. Most parts are exported to US and Europe with good quality.

4. Value the IP protection of the clients as a good OEM.

5. After-sale Service is guaranteed.

6. Offer one-stop solution from sample drawing, casting process, precision machining, assembling and packing.

More Product Photos

Raw Material, Sand Core, Machining and Warehouse:

Exhibition in Beijing

Our Company

Ningbo Plent Machinery is devoted to providing a "one-stop-solution" for our clients' needs, from tooling design, aluminum casting, machining and assembly in the areas of auto parts, pumps, valves, nozzles and brackets etc. So we are a fully serviced company and able to save the cost and energy of the clients to the utmost. Good quality and Competitive prices are ensured by perfect testing equipment, quality inspection personals and selected chain suppliers. We are experienced in IP protection due to the innovation nature of the company. PLENT has become a preferred OEM supplier partnering with world leading company in US and Europe.

Distinguished as top-tie partner of companies to outsource their engineering service and manufacturing business, our service are featured by:

FAQ

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free if the cost is below USD20 with freight on your cost.

Q: How long is your delivery time?

A: Generally it is 5 days if the goods are in stock. Or it is 15 days if the goods are not in stock, it is according to quantity.

Q. what is your payment term?

A: T/T 30% payment in advance, balance to be paid prior shipment.

Q: what is your main market?

A: ,Western Europe,North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia.

Q: Can I have my own customized product?

A: Yes, we can supply logo Print and package desiged based in our MOQ.