Basic Info.

Product Description

Foundry Green Sand Moulding Machine Cast Iron Jolt Squeeze Microseism Molding Machine

1. Usage

TThis machine is suitable for mass production of medium-sized castings. Single-sided moulding plate or single flask moulding, cope or drag. This machine adopts spring micro-shock compaction mechanism. higher compacting cylinder diameter and large pressing force, uniform and even sand moulding , which plays a certain role in improving the quality of castings.

The mould lifting structure adopts the pneumatic oil mode, and the two mold cylinders, the connecting rods, the synchronous shaft to realize smooth lifting. Simple pneumatic pipeline , easy and flexibleto operate, convenient to use and maintain.

2. Characteristics

A. The molding machine is a fully buffered, high frequency, low amplitude, pneumatic microseismic compaction molding machine.

B. Using spring buffer, the pneumatic micro-shock mechanism can reduce the impact of the shock on the foundation.

C. The body parts of the microseismic compaction molding machine are all made of steel, which greatly improves the rigidity.

D. The vibration mechanism consists of a workbench, a shock piston, a trembling compaction piston, and a compaction cylinder..

E.The mould-lifting mechanism consists of the synchronous shaft of the mold-cylinder connecting rod and the ejector pin. The mould-lifting mechanism cylinder is controlled by pneumatic oil to ensure the smoothing of the mold.

3. Main technical specifications

| No. | Item | AT145W | AT146W | AT147W | AT147Q | AT148W | AT149Q |

| 1 | Max size of moulding flask(mm) | 500*450*300 | 600*500*200 | 650*550*250 | 750*650*300 | 800*600*300 | 1000*800*320 |

| 2 | Size of workbench(mm) | 620*520 | 700*550 | 750*600 | 850*700 | 900*730 | 1100*850 |

| 3 | Compressed air(Mpa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| 4 | Compaction force(kgf) | 6300 | 7000 | 8000 | 9500 | 10000 | 15000 |

| 5 | Jolting load(kgf) | 300 | 300 | 400 | 500 | 600 | 800 |

| 6 | Compaction stroke(mm) | 160 | 160 | 200 | 200 | 200 | 250 |

| 7 | Mould lifting stroke(mm) | 200 | 200 | 220 | 250 | 350 | 350 |

| 8 | Distance between compaction head to work bench(mm) | 300-450 | 350-450 | 450-600 | 550-650 | 600-700 | 700-800 |

| 9 | Distance between compaction head to ground(mm) | 780 | 800 | 800 | 850 | 860 | 900 |

| 10 | Productivity(mold/hour) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

| 11 | Overall dimension(mm) | 1200*1000*1700 | 1400*1000*1700 | 1200*1100*1800 | 1250*1100*1900 | 1800*1300*2300 | 1060*1660*2300 |

Remark: Machine model can be customized according to customer's exact requirements.

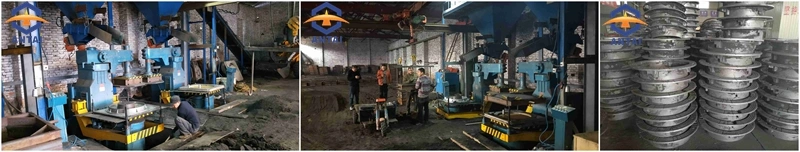

4. Machine Photos

5. Contact Us