- Overview

- Product Description

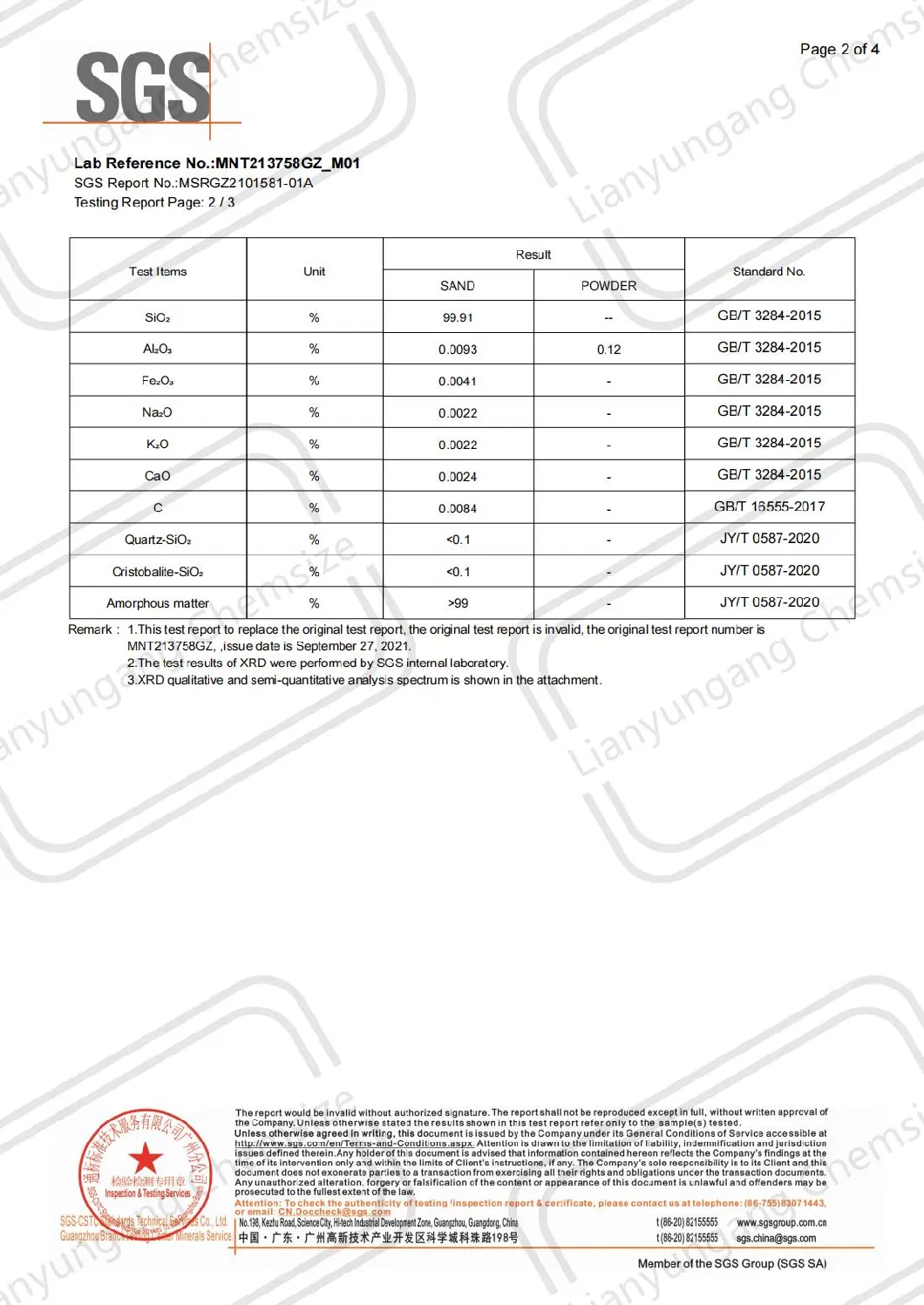

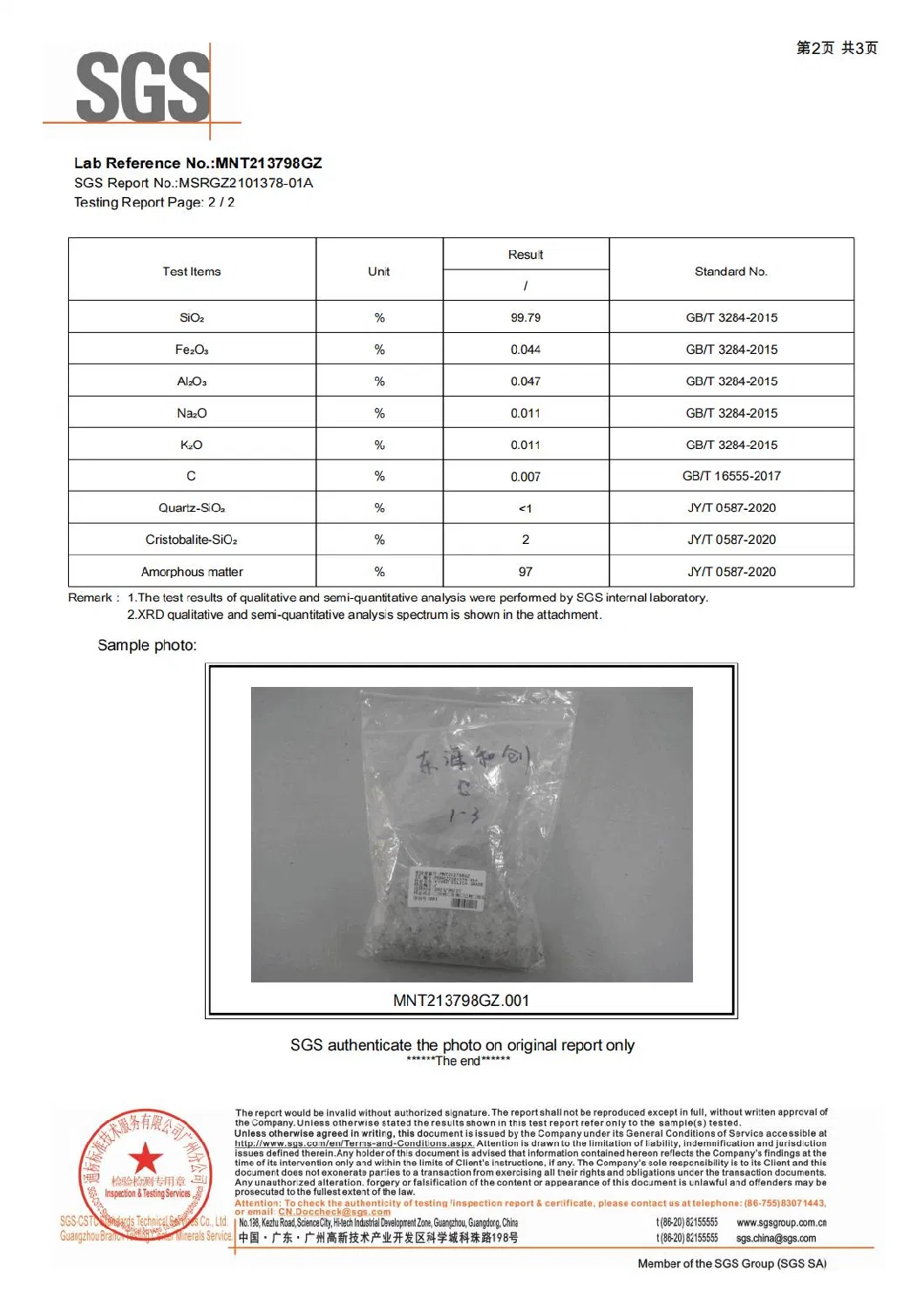

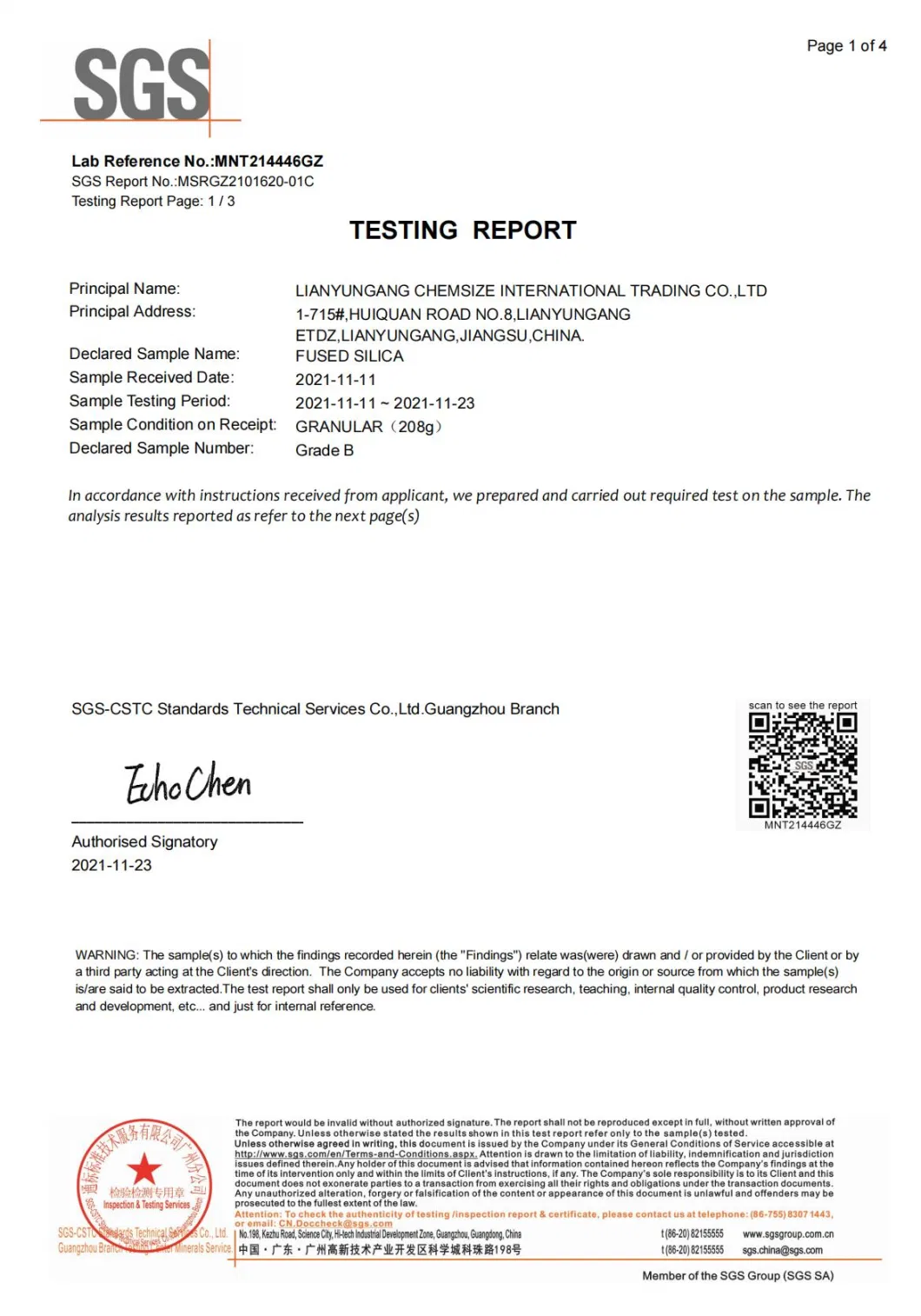

- Third Party Test Report

- Production Process

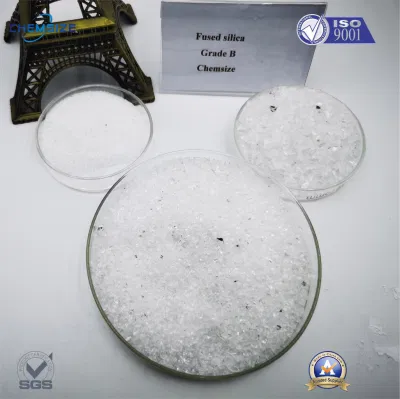

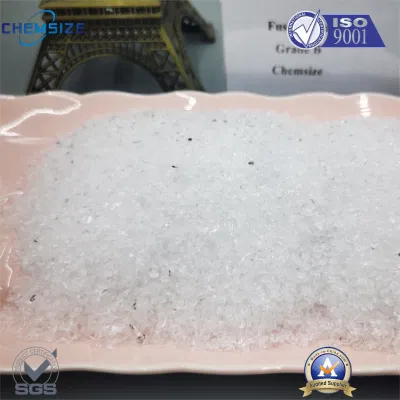

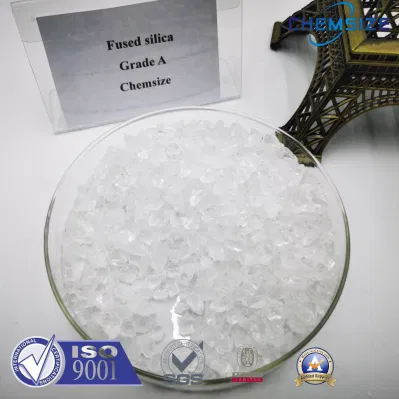

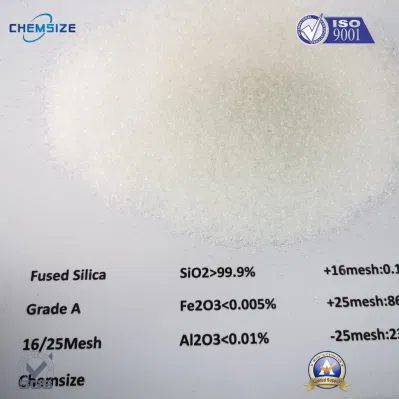

- Detailed Photos

- Packaging & Shipping

Basic Info.

Product Description

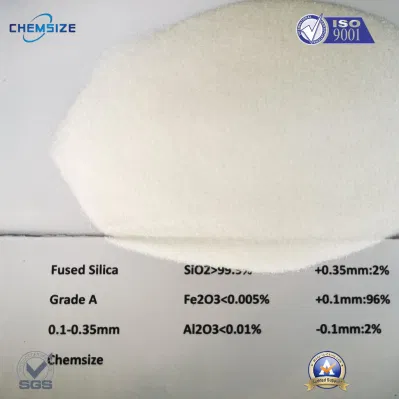

Electrofused Silica Sand

Welcome to Lianyungang Chemsize International Trading Co., Ltd., your trusted manufacturer of premium quality fused silica sand and powder. We take pride in providing the best service and highest quality products to our valued customers.

Product Overview

Electrofused Silica Sand

Our Electrofused Silica Sand, made from high-quality quartz, is the perfect solution for your foundry casting needs. With exceptional purity and consistency, this product guarantees superior performance in various applications.

Features and Benefits

- Meticulously crafted using advanced fusion technology for exceptional purity and consistency.

- Free from impurities, making it ideal for refractory materials and investment casting.

- Offers excellent flowability due to its fine particle size, allowing for precise and intricate casting designs.

- High melting point and low thermal expansion properties ensure superior performance even under extreme temperatures.

- Available in multiple mesh sizes, including 30+50mesh, 50+100mesh, 200mesh, and 325mesh, catering to a wide range of applications.

Invest in Quality

Invest in our Electrofused Silica Sand and experience the benefits of using a top-notch product that guarantees excellent results in your foundry casting processes. Trust Lianyungang Chemsize International Trading Co., Ltd. for exceptional quality, reliability, and performance.

Grade A Fused Silica Sand & Powder Specifications

Grade A Fused Silica Sand & Powder Specifications

Product Name: Electrofused Silica Sand

Mesh Sizes: 30+50mesh, 50+100mesh, 200mesh, 325mesh

Application: Foundry Casting, refractory, investment casting, thermal ceramic, ramming mass, refractory bricks, powder coating, dental material, quartz marble, epoxy molding compound, fusion bonded epoxy powder coating, and other special applications.

Attributes: ISO Certified

Keywords: Fused Quartz, Fused Silica Cullet, Quarzglas, Fused Silica Powder, Fused Silica Flour, Fused Silica Lumps, Fused Silica Sand, Fused Silica Grains, Silica Powder, Refractory, Quartz Powder, Quartz Sand, Quartz, Amorphous, Silicon Oxide, Castables, Motar, Investment Casting, Fused Silica Grit

Type: Quartz

Supplier: Lianyungang Chemsize International Trading Co., Ltd.

| 1. | Physical Properties | |||

| 1.1 | Composition | SiO2 | ||

| 1.2 | Structure | Amorphous | ||

| 1.3 | Colour | Transparent or white | ||

| 1.4 | Melting Temperature | approx.1750ºC | ||

| 1.5 | Specific Gravity | 2.21g/cm3 | ||

| 1.6 | Hardness | 7 Mohs | ||

| 1.7 | Thermal Expansion | 0.5*10-6 | ||

2. | Chemical Properties | |||

| Grade A | Grade B | Grade C | ||

| 2.1 | SiO2 | >99.9% | >99.85% | >99.7% |

| 2.2 | Al2O3 | <100ppm | <150ppm | <0.05% |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | ||||

| 2.3 | Fe2O3 | <30ppm for grain | <60ppm | <0.05% |

| 2.4 | CaO | <30ppm | <60ppm | <0.02% |

| 2.5 | Na2O | <30ppm | <60ppm | <0.02% |

| 2.6 | K2O | <30ppm | <60ppm | <0.02% |

Product Description

Product Name: Electrofused Silica Sand

Particle Size Distribution:

- 30+50mesh

- 50+100mesh

- 200mesh

- 325mesh

Application:

Foundry Casting

Attributes:

- ISO Certified

- Suitable for Rubber, Ceramic, and Casting Applications

Keywords:

Fused Quartz, Fused Silica Cullet, Quarzglas, Fused Silica Powder, Fused Silica Flour, Fused Silica Lumps, Fused Silica Sand, Fused Silica Grains, Silica Powder, Refractory, Quartz Powder, Quartz Sand, Quartz, Amorphous, Silicon Oxide, Castables, Motar, Investment Casting, Fused Silica Grit

Company name:

Lianyungang Chemsize International Trading Co., Ltd.

| Standard | |||||||

| 10-20 | 30-50 | 50-100 | -120 | -200 | -325 | ||

| Mesh | Microns | ||||||

| +8 | 2360 | <2 | |||||

| +12 | 1700 | 6-25 | |||||

| +16 | 1180 | 33-50 | |||||

| +20 | 850 | 25-45 | <1 | ||||

| +30 | 600 | 13 | 25-40 | ||||

| +40 | 425 | 32-45 | |||||

| +50 | 300 | 15-30 | <13 | ||||

| +70 | 212 | 30-60 | |||||

| +80 | 180 | 0-11 | <1 | ||||

| +100 | 150 | 28-51 | <10 | <1 | |||

| +140 | 106 | 4-16 | 7-13 | <10 | |||

| +200 | 75 | <2 | 10-15 | <10 | <3 | ||

| +325 | 45 | 14-20 | 15-30 | 4-11 | |||

| Pan | <3 | <2 | <1 | 45-55 | 70-80 | 86-97 | |

Fused Silica

Company Name: Lianyungang Chemsize International Trading Co., Ltd.

Special Feature: Fused Silica offers an extremely low coefficient of thermal expansion, consistent chemistry, and carefully controlled particle size distribution.

Applications: Fused Silica is widely used in various industries including thermal ceramic, refractory, investment casting, EMC, solar crucible, quartz marble, and powder coating.

Available Sizes:

- 0-1mm

- 1-3mm

- 3-5mm

- 0.2-0.5mm

- 0.1-0.5mm

- -10mesh

- 10-20mesh

- 30-50mesh

- 50-100mesh

- -100mesh

- -150mesh

- -270mesh

- 30-60mesh

- 60-120mesh

- 40-70mesh

- 70-140mesh

- 100-200mesh

- 120F

- 200mesh

- 325mesh

- 400mesh

- 600mesh

- 800mesh

- 1250mesh

- etc...

Note: Particle size can be produced according to customer's special requirements.

Fused Silica Production Process

Fused Silica Production Process

Fused silica is a high purity quartz sand that has been melted to form glass. Its high volume stability, low volumetric expansion, and high purity make fused silica a versatile material for refractory applications, such as aluminum launders and other highly cyclical applications.

At Lianyungang Chemsize International Trading Co., Ltd., we strictly choose high purity silica sand (SiO2 > 99%) from local Donghai/Xinyi as our raw material. The silica sand is melted at a high temperature of 2000-2300 ºC, resulting in an amorphous silicon dioxide glassy ingot. After cooling, we further process the ingot into fused silica lumps, sand, and powder according to our customers' requirements.

Fused Silica High Clear Pictures

Discover the exceptional quality of our Electrofused Silica Sand, available in various mesh sizes (30+50mesh, 50+100mesh, 200mesh, 325mesh) for Foundry Casting. Our product, also known as Fused Quartz, offers a range of applications including Rubber, Ceramic, and Casting. With ISO certification, our Fused Silica is a top choice for Refractory purposes, offering outstanding performance. Choose from our selection of Fused Silica Cullet, Quarzglas, Fused Silica Powder, Fused Silica Flour, Fused Silica Lumps, Fused Silica Sand, Fused Silica Grains, Silica Powder, Quartz Powder, Quartz Sand, Quartz, Amorphous, Silicon Oxide, Castables, Motar, and Investment Casting. Experience the excellence of Fused Silica Grit from Lianyungang Chemsize International Trading Co., Ltd.

Product Description

Product Name: Electrofused Silica Sand for Foundry Casting

Keywords:

- Fused Quartz

- Fused Silica Cullet

- Quarzglas

- Fused Silica Powder

- Fused Silica Flour

- Fused Silica Lumps

- Fused Silica Sand

- Fused Silica Grains

- Silica Powder

- Refractory

- Quartz Powder

- Quartz Sand

- Quartz

- Amorphous

- Silicon Oxide

- Castables

- Motar

- Investment Casting

- Fused Silica Grit

Attributes:

- ISO Certified

- Applications in Rubber, Ceramic, Casting, Quartz Type

Package and Delivery:

Fused Silica is packaged in 25kg net plastic woven bags and placed on pallets.

Reference Information:

Company name: 'Lianyungang Chemsize International Trading Co., Ltd.'

Fused Silica Factory and Quality Control Pictures

Lianyungang Chemsize International Trading Co., Ltd.

Fused Silica Factory and Quality Control Pictures

Explore our state-of-the-art fused silica factory and witness our meticulous quality control process. At Lianyungang Chemsize, we take pride in offering a diverse range of high-quality fused silica products to meet your specific needs. Our electrofused silica sand is available in various mesh sizes, making it ideal for foundry casting applications.

Rest assured, our products are ISO certified, guaranteeing their exceptional quality. Whether you work in the rubber, ceramic, or casting industries, our fused silica products are designed to deliver outstanding performance.

Choose from our wide selection of fused quartz, silica powder, silica sand, and more. Each product is carefully manufactured to ensure superior refractory properties, making them the perfect choice for your projects.

Experience the difference that our premium refractory materials can make. Invest in the best for your projects with Lianyungang Chemsize International Trading Co., Ltd.

Fused Silica Sand

Fused Silica Sand

Fused Silica Sand is a high purity crystal silica product made through the electric fusion process. It is specially engineered into various forms such as lumps, cullet, ingots, sand, grain, granular, and powder flour. This product is designed for various applications including making PV fused silica crucible, thermal ceramic, refractory, EMC investment casting ceramic shell, and more.

Appearance and Specifications

- Must not contain any unfused parts

- Should not have any foreign materials such as string, plastic line, carbon or wooden material, metal, or other outside contaminants

- Conditional black dots are acceptable, but all other color dots are forbidden

- Black spot diameter should not exceed 2mm

- Total black dots quantity should be less than 10 when opening the big bag, with a maximum of 10 dots per square meter

For more information, please contact Lianyungang Chemsize International Trading Co., Ltd.

FAQ

Fused Silica Products

Fused Silica Products

Thank you for your interest in our fused silica products. Below, you will find answers to some frequently asked questions:

Q1. Can I have a sample order for fused silica products?

A: Yes, we'd be happy to send samples free of charge by ***/FEDEX/DHL. Mixed samples are also acceptable.

Q2. What is the lead time?

A: The lead time for sending samples is 3-5 days. For delivery orders with a quantity within 100mt, it is usually within 15 days.

Q3. Is there any MOQ limit for fused silica sand order?

A: No, there is no MOQ limit. However, please note that the average cost will be higher for smaller orders.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx, or ***, which takes approximately 3-5 working days to arrive. Shipping by sea may take 7-40 days depending on the distance.

Q5. How to process an order for fused silica powder products?

A:

1) Let us know your requirements or application.

2) We will provide a quote based on your requirements or our suggestions.

3) Once the customer confirms the samples, they can pay the deposit for the formal order.

4) We will arrange the production accordingly.

Q6. Is it possible to print my logo on the packages?

A: Yes, please inform us formally before our production and confirm the design based on our sample.

Q7: How do you deal with faulty products?

A: Firstly, our products are produced in a strict quality control system, resulting in a defective rate of less than 0.2%. However, if any issues arise, we will arrange to send new products to you and cover all your losses.

For any further questions, please feel free to contact us!

Company Name: Lianyungang Chemsize International Trading Co., Ltd.

Chemsize Fused Silica

Chemsize, a leading manufacturer of Fused Silica (grains & powders), offers high-quality materials used in various industries such as Refractory, Investment Casting, Technical Ceramic, and EMC filler. Our Fused Silica materials have received positive feedback from all our customers.

Chemsize Fused Silica stands out with its exceptional properties. It has a higher fusion ratio, with Amorphous SiO2 up to 99.9%min, low iron content (30ppm max), and low impurities. As a result, our materials have a very low coefficient of thermal expansion, high resistance to thermal shock, and extremely low electrical conductivity. Our special blending and sieving process, along with the use of a Malvern Laser Particle Size Analyzer, ensures that we always supply our customers with the most suitable Fused Silica materials.

We produce our Fused Silica using a unique, proprietary electric-arc fusion technique. This results in Fused Silica of the purest quality in China, with over 99.9% SiO2. It is amorphous, with a low coefficient of thermal expansion, high resistance to thermal shock, and excellent size integrity made to ISO-certified standards. Our Fused Silica is inert, exhibiting excellent chemical stability and extremely low conductivity.

Our Fused Silica products have an extremely low thermal expansion coefficient, consistent chemistry, and carefully controlled particle size distribution. They are specially engineered grains and powders designed for use in foundry, refractory, investment casting, and other special applications.

In investment casting, our Teco-Sil Fused Silica is known for its volume stability. With its extremely low thermal expansion coefficient, it allows for the production of tight tolerance castings with easy shell removal.

Our standard package is a 25kg bag, with 48 bags per pallet or jumbag with a net weight of 1200kgs. We also offer tailored shipments for customers who prefer bulk bags of varying sizes.

Fused Silica Applications

- Fused silica can be used to make crucibles for solar cell production in the photo-voltaic industry.

- In the glass industry, fused silica is used to make rollers, castables, mortars, gunning mixtures, and forming tools.

- In the thermal resistance industry, fused silica is used to make technical ceramics.

- In the investment casting industry, fused silica is used to make ceramic slurry.

- Fused silica is also used in various other applications such as acid refractory, resin fillers, EMC fillers, powder coating, and more.

Choose Chemsize Fused Silica for its superior quality and exceptional performance in a wide range of applications.

Reference: Lianyungang Chemsize International Trading Co., Ltd.