- Overview

- Product Description

- Detailed Photos

- Technics Flow

- QC Control

- Packaging & Shipping

- What We Do?

- FAQ

Basic Info.

Model NO.

258

Application

Machinery Parts

Machining

CNC Machining

Material

Iron

Surface Treatment

Spray-Paint

Surface Roughness

Ra0.8

Standard

ASTM

Certification

ISO 9001:2000

OEM Service

Yes

MOQ

200PCS

Lead Time

About 35 Days

Guarantee

1 Year

Transport Package

Normal Export Carton Box+Wooden Case/Pallet

Specification

ISO9001: 2000

Trademark

Seger

Origin

Shandong, China

Production Capacity

50, 000 PCS Per Month

Packaging & Delivery

Package Size

10.00cm * 8.00cm * 6.00cm

Package Gross Weight

1.800kg

Product Description

Gray iron grey iron Ductile Cast Iron Foundry

Material | Gray iron ,ductile iron,stainless steel,carbon steel,aluminum ,brass etc |

| standard | DIN, ASTM, BS, JIS etc. |

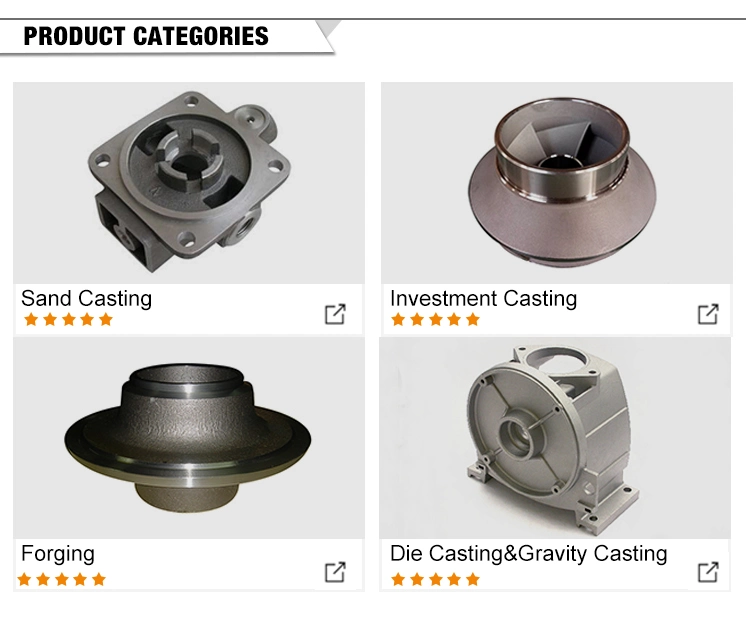

| process | sand casting, investment casting(lost wax casting), die casting ,gravity casting ,forged etc,if your parts are complex which need different comprehensive technics,it's also no problem.Other technics of welding,bending,stamping,we also have cooperated suppliers and you may enjoy one-stop service. |

| Weight range | 0.5-500kg |

| Surface treatment | painting, polishing, heat treatment, plaining or galvanization etc. |

| Machining | complete machining such as Machining center, CNC, Lathe, Milling machine,drilling etc. |

| Size and design | As per the customer's drawings and requirements |

| As per the customer's samples | |

| Packing | Seger normal export packaging |

| As per customers' requirements | |

| Inspection | Foundry in-house |

| Third Party inspection available upon customers requirements |

At Seger industrial, we produce a huge range of products and are continually expanding our services to customers. This area shows images of some of our recent work to show the scope available to our clients. This is just a sample of what we can do, so please contact us for more information.

cast iron wheel hub

cast iron burner grate

cast iron engine parts

cast manifold

cast iron pump housing

ADI casting parts

We can supply products with the following test reports:

1) Chemical composition report

2) Tensile strength report

3) Brinell hardness report

4) Metallographic structure report

5) Key dimension checking report

6) Full dimension report

7) Third part test report

We will design each speical checking tooling control key dimension during production to ensure each key dimension under control.

a>Seger packing:carton box+wooden case/pallet/iron cage

b>As pre client's special requirement

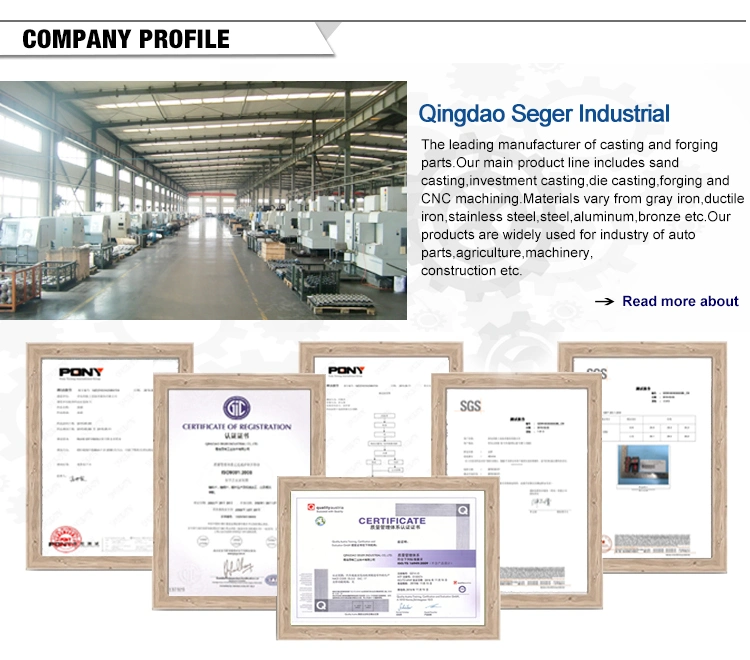

Company info:

Q1:What's the lead time?

A1: In general,the lead time is about 30~40 days for opening new moulds and mass production.

Q2:What file formats does Seger accept for drawings:

A2:The company ca accept a range of formats for drawings,but the main ones are detailed below:2-D PDF AND TIFF 3-D STL,IGES,STEP,Solidworks,etc

Q3:Is it possible to visit seger to view it's manufacturing process?

A3:We are extremely proud of our facility and existing customers to visit our company.we think you will be impressed by us,as well as the warm welcome from our friendly,experienced team.

For more details,pls feel free to contact lisa.24 hours service for you.