Basic Info.

Certification

CE, ISO9001

Type

Sand Casting

Specification

Non-standard size

Trademark

SZ

Origin

Suzhou, China

HS Code

84748090

Production Capacity

15 Sets/Year

Product Description

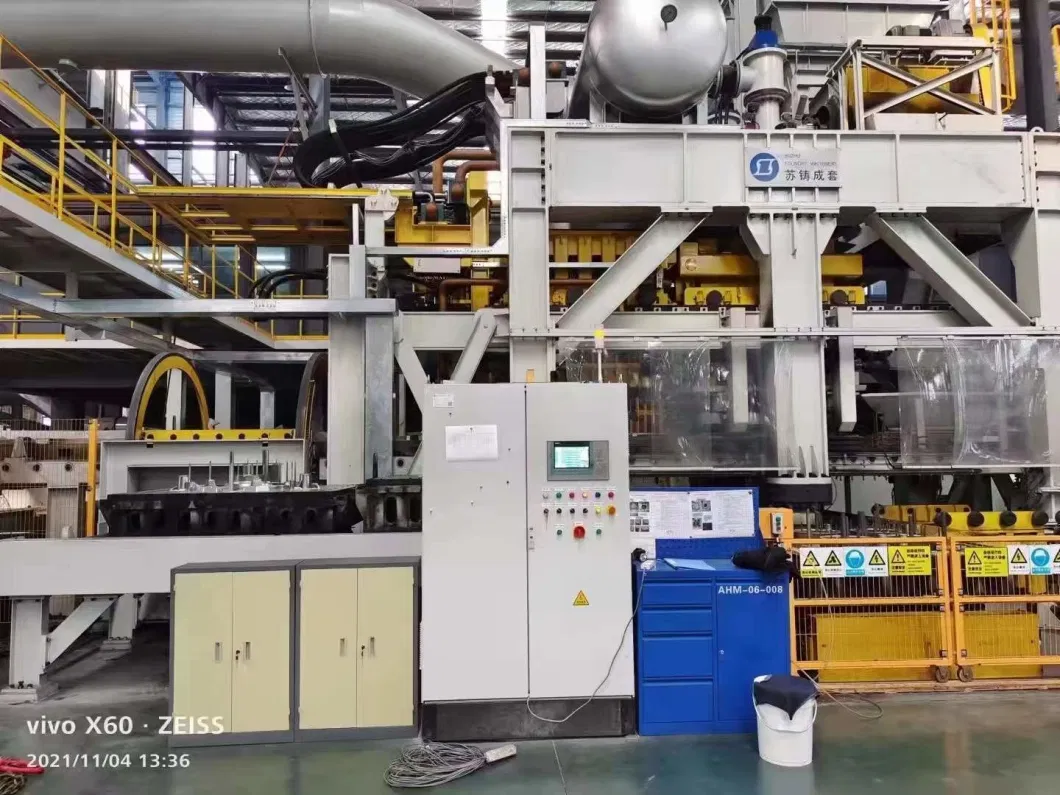

Static Pressure Horizontal Automatic Molding Line

Product Detail:

Productivity of moulding lines

up to 210 mould per hour achieved Plants with higher productivity may be designed on request.

Size of moulds up to 2500 mm length

Plants with larger flask may be designed on request.

Product Orientation

1. High ability for compaction sand, rigid and dense mould, suitable to manufacture of complex castings.

2. Dimensional stability and better surface roughness ,high efficiency of moulding

3. Mould plate with high rate of utilization. Good working condition and labour saving

A. Process of molding machine

1. Empty Flask is indexed into the molding machine molding station

2. Pattern bolsters rotate or shuttle

3. The lifting cylinder rises, and the formwork, sand box and pre-sand frame rise

4. Quantitative sand adding

5. Move the sand bucket out while moving the multi-contacts in and clean the upper surface of the pre-sand frame

6. The lifting cylinder goes up again to top tight

7. Air pre-compacting and compaction

8. The lifting cylinder falls down while drafting

Static Pressure has following advantages.

High ability for compaction sand, rigid and dense mould, suitable to manufacture of complex castings.

Dimensional stability and better surface roughness.

High efficiency of moulding.

Mould plate with high rate of utilization.

Good working condition and labour saving.

-PLC from SimensS7, with touch screen and network Ethernet etc.

-Servo system from SEW or Siemens and and Variable-Frequency Drive from Rexroth.

-Hydraulic valve of moulding machine from Rexroth, Hydraulic Cylinder from China famous brand.

-Low-voltage electrical components from Schneide.

-Hydraulic Seals from international brand.

-Bearing from China famous brand (HRB/LYC/ZWZ).

Quality Control

Company profile

The company SUZHU is located in the beautiful ancient southern Chinese city - Suzhou, near Shanghai and in the centre of the China Yangtze River Delta Economic Zone.

SUZHU is specialized in engineering, technology development, design, production, supply and start-up of different kinds of equipment for foundries including technology:

- moulding

- core making and handling

- pouring

- grinding.

Suzhou Suzhu Foundry Machinery Manufacture Company Ltd. is based on the company Suzhou Foundry Machinery Works, which was established in 1962 and is the oldest Chinese foundry equipment producer. In 2009, after privatisation the company moved to Suzhou High-Tech Development Zone with new design and production facilities. With excellent experience in the foundry industry for more than 50 years, SUZHU has become the leading company for foundryequipment and foundry technology in China. SUZHU did successfully provide many foundries with complete solutions as turnkey projects.