- Home

- Low Pressure Die Casting

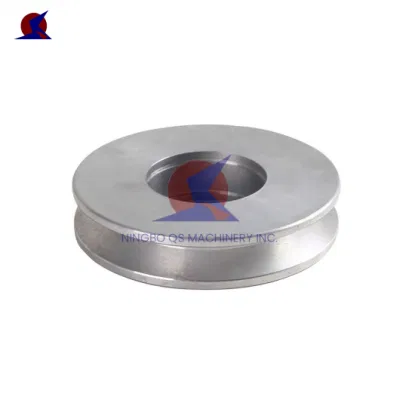

Low Pressure Die Casting Manufacturer in China - Premium OEM Supplier

Introducing our latest innovation in metal casting technology – Low Pressure Die Casting, brought to you by Jiangsu Hongli Machine Co., Ltd. This advanced manufacturing process employs low pressure to fill the die with molten metal, resulting in highly accurate and high-quality parts. The low pressure exerted during casting ensures a smooth and compact filling of the mold, reducing the risk of porosity and shrinkage in the final product. Our state-of-the-art equipment and expertise in die casting allow us to produce components with intricate designs and superior surface finish. With Low Pressure Die Casting, we can meet the demands of various industries, including automotive, aerospace, and electronics, by delivering parts with excellent dimensional stability and mechanical properties. Trust Jiangsu Hongli Machine Co., Ltd. for reliable, efficient, and cost-effective solutions for your die casting needs.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

China OEM ODM CNC Machined Iron Steel Investment Sand Casting Bearing Housing Part

Looking for high-quality CNC machined iron and steel bearing housing parts? Our China factory specializes in OEM and ODM production.

China Manufacturer Pure Quartz Sand

Get high-quality {China Manufacturer Pure Quartz Sand} directly from our factory. Our dedicated team ensures top-grade quartz sand for all your industrial needs.

QS Machinery Gravity Die Casting Foundry Customized Top Gravity Casting Service China Gravity Casting Moulds

Looking for customized top gravity casting service? Visit QS Machinery Gravity Die Casting Foundry for China gravity casting molds. We are a leading factory.

Traction Lug R-1 Tractor Tyre Mould Mold Making

Looking for a reliable Traction Lug R-1 Tractor Tyre Mould Mold Making factory? Our experienced team delivers top-quality products for all your agricultural needs.

OEM Precision Machining Ductile Iron Sand Casting Parts Custom Cast Iron Foundry Metal Foundry Aluminum Sand Casting

OEM Precision Machining Ductile Iron Sand Casting Parts from our metal foundry. Custom cast iron and aluminum sand casting solutions. Factory direct.

Automatic Static Pressure Green Sand Moulding Line, Foundry Machine

Explore our high-quality Automatic Static Pressure Green Sand Moulding Line and Foundry Machine. As a factory, we provide top-notch products for your manufacturing needs.

Brown Corundum Sand Used for Workpiece Material Blasting Process Requirements

Brown Corundum Sand for precision blasting needs. Our factory provides top-quality material for workpiece blasting process. Contact us for a quote.

Gray Iron Ductile Iron FC300 Machine Tool Casting

Get high-quality Gray Iron Ductile Iron FC300 Machine Tool Casting from our factory. Durable and reliable products for all your machinery needs.

Sand Castings in Stainless/Carbon Steel/Cast Iron Used in Machinery/Mining Industry

Introducing "ForgeTech Sand Castings" for Machinery and Mining Industry. High-quality stainless/carbon steel and cast iron products. We are a trusted factory.

4-25 Automatic Hydraulic Sand Fly Ash Paving Interlocking Cement Brick Block Molding Machine

Get the best 4-25 Automatic Hydraulic Sand Fly Ash Paving Interlocking Cement Brick Block Molding Machine from our factory. High quality and efficient production.

KOCEL Customized Sand Mold for Auto Spare Parts by Rapid Prototyping with 3D Printing Sand Casting & CNC Machining for Stainless Steel Metal Parts

Introducing KOCEL's Rapid Prototyping with 3D Printing Sand Casting & CNC Machining for Stainless Steel Metal Parts. We are a premier factory for custom auto spare parts.

OEM Casting Parts Vacuum Casting with Drawings Metal Steel Investment Casting

OEM Casting Parts Vacuum Casting with Drawings Metal Steel Investment Casting - Find high-quality casting parts at our factory. Contact us for custom metal solutions.

Metal Piece Plastic Vacuum Models Truck Components Die Cast Mold Making Service Sand Casting Service

MetalTech Industries: Your go-to factory for top-quality Metal Piece Plastic Vacuum Models Truck Components Die Cast Mold Making Service Sand Casting Service.

Premium Fused Silica Sand Supplier 1-3mm Mesh Size

Get high-quality Premium Fused Silica Sand Supplier 1-3mm Mesh Size directly from the factory. Perfect for industrial and manufacturing applications.

OEM China Factory Steel/Aluminum Die Casting/Sand Casting/ for Auto

Factory Steel/Aluminum Die Casting/Sand Casting for Auto - OEM China. Quality casting, competitive prices. Contact us for custom solutions.

OEM Customized Auto Motorcycle Spare Parts Rapid Prototyping Metal Gravity Casting by 3D Printing Sand Casting & Low Pressure Casting & CNC Machining

Rapid Prototyping Metal Gravity Casting for OEM Customized Auto Motorcycle Spare Parts. We are a factory specializing in 3D Printing, Sand Casting, Low Pressure Casting, and CNC Machining.

Furan Alkaline Phenolic Resin Sand Mixer Mixing Machine Supplier

We are a leading factory specializing in the production of Furan Alkaline Phenolic Resin Sand Mixer Mixing Machine. Contact us for top-quality industrial equipment.

Ductile Iron Green Sand Casting for Foundry Casting Process

Ductile Iron Green Sand Casting for Foundry Casting Process - Shop our quality products from a reliable factory. Get exceptional casting solutions now!

Factory Hot Selling S52 Centrifugal Regenerator Machine

Discover the high-performance Factory Hot Selling S52 Centrifugal Regenerator Machine. We are a leading factory dedicated to quality and innovation.

Zinc Brass Casting Lock Part Automatic Polishing Machine Buffing Machine

Zinc Brass Casting Lock Part Automatic Polishing Machine Buffing Machine available at our factory. High-quality, efficient polishing equipment for industrial use.

- Top Low Pressure Die Casting Manufacturer in China - Wholesale Supplier

- Reviews

- Related Videos

Introducing our new low pressure die casting method, a highly efficient and cost-effective process for producing high-quality metal components. With this advanced technology, we are able to create complex and intricate parts with excellent dimensional accuracy and surface finish.

Our low pressure die casting technique involves injecting molten metal into a reusable steel die under low pressure, allowing for a more controlled and uniform filling of the mold cavity. This results in superior mechanical properties and reduced porosity in the finished products.

The benefits of low pressure die casting extend to various industries, including automotive, aerospace, and industrial machinery. Our process is ideal for producing lightweight, yet durable components such as engine blocks, transmission casings, and structural components for aircraft and machinery.

In addition to ensuring the highest quality and precision, our low pressure die casting method also offers shorter cycle times, leading to increased productivity and reduced overall production costs. Moreover, it allows for the use of a wider range of alloys, providing greater flexibility in material selection.

With our commitment to innovation and excellence, we are proud to offer the latest advancement in metal component manufacturing. Experience the advantages of low pressure die casting with our state-of-the-art technology and elevate your product performance and quality.

I recently purchased a low pressure die casting product for my manufacturing business and I couldn't be more satisfied with the results. The precision and quality of the casted parts are exceptional, and the process itself was efficient and cost-effective. The low pressure die casting technique resulted in uniform parts with minimal porosity and excellent surface finish. The product has definitely improved the overall quality of our finished products and has helped streamline our production process. I highly recommend low pressure die casting for anyone looking for high-quality, reliable casting solutions.

Mr. Qinan Huang

I recently purchased a low pressure die casting product and I couldn't be happier with the results. The quality of the casting was exceptional, with smooth and precise surface finishes. The low pressure process also ensured minimal porosity and defects, resulting in a high-quality final product. The efficient use of materials and reduced machining requirements also saved both time and costs. Overall, I highly recommend low pressure die casting for producing high-quality, complex parts with tight tolerances. It's a great solution for various industries and applications.

Ms. Tina Sun

Contact us

Ms. Helen Yang: Please feel free to give your inquiry in the form below We will reply you in 24 hours