- Home

- Low pressure casting rapid prototyping

Low Pressure Casting Rapid Prototyping Manufacturer in China

Introducing the newest innovation in rapid prototyping technology: low pressure casting. This cutting-edge technique, offered by Jiangsu Hongli Machine Co., Ltd., allows for the quick production of high-quality prototypes through the use of low pressure to fill the mold with molten metal. With minimal air entrapment and reduced porosity, low pressure casting delivers exceptional surface finish and dimensional accuracy, making it an ideal choice for creating complex and intricate designs.

This innovative process enables engineers and designers to efficiently test and iterate their product designs, saving valuable time and resources in the development phase. Whether it's for automotive components, aerospace parts, or consumer goods, low pressure casting provides a cost-effective solution for producing prototype samples with excellent mechanical properties.

Experience the next level of rapid prototyping with low pressure casting from Jiangsu Hongli Machine Co., Ltd. and bring your ideas to life with speed and precision.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

510X610mm Flaskless Automatic Horizontal Sand Molding Machine for

Discover our 510X610mm Flaskless Automatic Horizontal Sand Molding Machine for efficient and precise casting. As a factory, we offer high-quality equipment for all your production needs.

Foundry Coated Sand Casting Shell Core Molding Machine

Get high-quality foundry coated sand casting shell core molding machines at our factory. Browse our selection for top-notch products.

3D Milling 1325 CNC Wood Router Machine for Foundry Patterns Moulds Molds

Looking for a reliable 3D Milling 1325 CNC Wood Router Machine for Foundry Patterns Moulds Molds? We are a factory that specializes in producing high-quality CNC machines.

Sand Casting Gravity Pressure Precision Metal Forging CNC Machining Machinery Shell Valve Pump Case Heatsink Bracket Base Cover Aluminum Zinc Alloy Die Casting

Aluminum Alloy Die Casting Factory - Providing high-quality Sand Casting, Gravity Pressure, Precision Metal Forging, and CNC Machining services."

880mm 1050mm Manufacturer Plastic and Sand Roofing Tile Making Resin Tile Machine Production Line

Product Name: Plastic and Sand Roofing Tile Making Resin Tile Machine Production Line SEO Description: Our factory manufactures a Plastic and Sand Roofing Tile Making Resin Tile Machine Production Line. Contact us for high-quality, efficient machines.

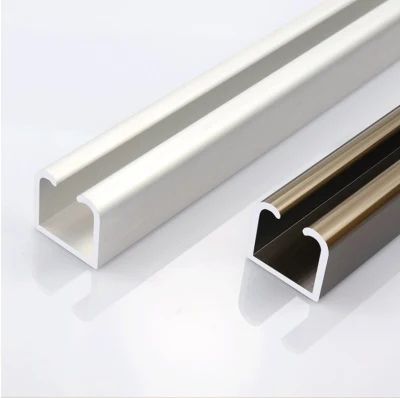

One Stop Solution Aluminium Alloy Solid Aluminum Track/Channel/Section Aluminum Mouldings

Looking for high-quality aluminum track, channel, and sections? Check out our One Stop Solution Aluminium Alloy Solid Aluminum Track/Channel/Section Aluminum Mouldings. We are a factory specializing in premium aluminum products.

2018 Hot Sale Plastic Concrete Interlocking Driveway Paver Mould

Get high-quality plastic concrete interlocking driveway paver mould at our factory. 2018 hot sale items available. Order now for durable and reliable products!

Colourful Non-Toxic Material Magic Modeling Sand Clay Educational Art Toy Space Sand

Introducing our Colourful Non-Toxic Material Magic Modeling Sand Clay Educational Art Toy Space Sand! We are a factory dedicated to providing quality and safe educational toys for children. Discover the endless possibilities of creativity with our magic sand clay.

OEM CNC Turning Milling Copper/Brass/Bronze for Screw Part

Get high-quality OEM CNC turning milling copper/brass/bronze screw parts from our factory. Precision machining for optimal performance.

Fly Ash Sand Cement Mixer Concrete Brick Moulding Machine

Introducing our Fly Ash Sand Cement Mixer Concrete Brick Moulding Machine. We are a factory specializing in top-quality construction equipment.

OEM Grey Cast Iron for Sand Casting Foundry

Get high-quality OEM Grey Cast Iron for sand casting foundry from our factory. We offer durable and reliable products for all your casting needs.

Motor Housing Motorcycle Engine Metal Auto Parts Vehicle Part Sand Casting Aluminum Alloy Ductile Iron Stainless Steel High Precision CNC Machining Parts

High Precision CNC Machining Parts - Custom Motor Housing, Motorcycle Engine, Metal Auto Parts. We are a leading factory specializing in sand casting, aluminum alloy, ductile iron and stainless steel products.

Cast Iron Moulding Machine, Moulding Machine for Cast Iron Manhole Cover

Looking for a reliable Cast Iron Moulding Machine or Moulding Machine for Cast Iron Manhole Cover? Look no further! Our factory has what you need. Fast and efficient production.

Horizontal/Vertical Sand Molding Machine, Automatic Sand Molding Machine for Casting Metal Covers

Get high-quality Horizontal/Vertical Sand Molding Machine and Automatic Sand Molding Machine for Casting Metal Covers at our factory. Contact us for custom solutions.

Waterjet Cutting 80 Mesh Garnet Sand with Factory Price

Get high-quality 80 mesh garnet sand for waterjet cutting at factory prices. We are a leading manufacturer offering competitive deals. Shop now!

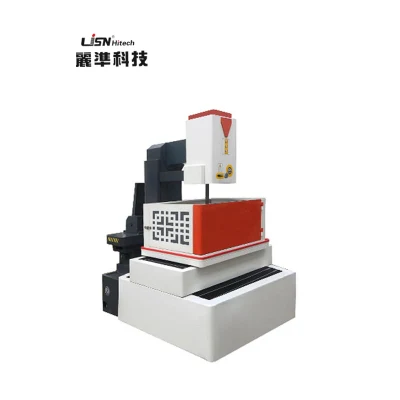

Ms-650AC Multifunctional CNC Wire Cutting EDM

Get precise wire cutting with the Ms-650AC Multifunctional CNC Wire Cutting EDM at our factory. High-quality results guaranteed. Contact us now!

Training Fitness Gym Strength Competition 4, 5, 6, 10 Kg Kettlebells Cast Iron Kettlebell with Grip

Get in shape with our Training Fitness Gym Strength Competition Kettlebells. Available in 4, 5, 6, and 10 Kg, our cast iron kettlebells have a comfortable grip. As a factory, we offer high-quality products for your fitness needs.

Yachts Fitting Motor Housing Customized Part Foundry Stainless Steel Truck Motor Part by Rapid Prototype of 3D Printing Sand Casting & Machining

Customized Stainless Steel Motor Housing by 3D Printing & Machining. Our foundry specializes in rapid prototype for yachts, trucks, and more.

High Whiteness Fused Silica Powder and Sand for Making Quartz Marble

Get high whiteness fused silica powder and sand for making quartz marble at our factory. Pure and premium materials for superior quality products.

Manufacturer ISO9001 Custom Ductile Cast Iron Casting

Get top-quality Manufacturer ISO9001 Custom Ductile Cast Iron Casting at our factory. We specialize in precision casting and offer reliable products.

- Low Pressure Casting Rapid Prototyping: Manufacturer for OEM Solutions in China

- Reviews

- Related Videos

Introducing our innovative low pressure casting rapid prototyping service. This cutting-edge technology allows for the creation of high-quality metal prototypes in a quick and cost-effective manner.

At our facility, we use the latest low pressure casting equipment to produce prototypes with exceptional precision and surface finish. This process is ideal for creating complex and intricately detailed parts, while also ensuring minimal material waste.

Our rapid prototyping service is perfect for businesses looking to accelerate their product development cycle. Whether you need a single prototype or a small batch of parts, our low pressure casting process can deliver on time, every time.

We understand that speed is of the essence when it comes to prototyping, which is why we have optimized our production process for maximum efficiency. This means you can expect fast turnaround times without compromising on quality.

By leveraging low pressure casting rapid prototyping, you can test and validate your designs more quickly, ultimately reducing time to market and saving on development costs.

Get in touch with us today to learn more about how our low pressure casting rapid prototyping service can benefit your business. Let us help you bring your ideas to life with precision and speed.

I recently used the low pressure casting rapid prototyping technique to create a product prototype, and I must say I am extremely impressed with the results. The quality of the prototype produced using this method is outstanding, with smooth surfaces and accurate dimensions. The low pressure casting process allowed for quick and efficient production, saving me both time and money in the prototyping phase. I also found the finished prototype to be sturdy and durable, making it perfect for testing and showcasing to potential clients. Overall, I highly recommend low pressure casting rapid prototyping for anyone looking to create high-quality product prototypes.

Mr. Chuanbiao Xu

I recently used a low pressure casting rapid prototyping service to create a product prototype and I was extremely impressed with the results. The low pressure casting process produced a high-quality and precise prototype, which was exactly what I was looking for. The rapid prototyping aspect also saved me a lot of time in the product development process, allowing me to quickly move on to the next stages of production. The customer service was also exceptional, with the team providing regular updates and addressing any concerns I had. I highly recommend low pressure casting rapid prototyping for anyone looking to create accurate and efficient prototypes.

Ms. Leina Chen

Contact us

Ms. vivian zhang: Please feel free to give your inquiry in the form below We will reply you in 24 hours