- Home

- Lost wax investment casting

Lost Wax Investment Casting Manufacturer in China - Wholesale Supplier and Exporter

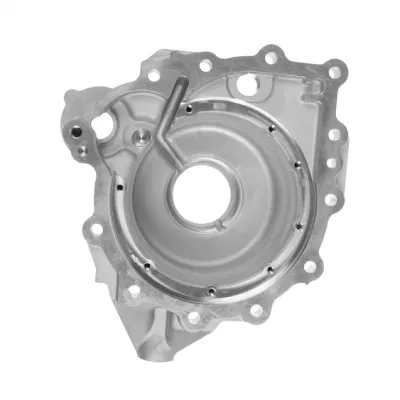

Introducing Jiangsu Hongli Machine Co., Ltd.'s advanced lost wax investment casting process. Our precision casting technique produces highly detailed and complex metal components with exceptional consistency and quality.

Using this method, a wax model of the desired part is coated with refractory material to create a mold. Once the mold is set, the wax is melted and drained, leaving a hollow mold that is then filled with molten metal. After solidification, the mold is broken to reveal the finished metal part, with precise details and smooth surfaces.

Our lost wax investment casting process allows for the production of intricate parts that may be difficult or impossible to produce with other methods. With a keen attention to detail and the use of state-of-the-art technology, Jiangsu Hongli Machine Co., Ltd. ensures that each component meets the highest standards of quality and reliability. Experience the advantages of our advanced casting process by choosing our products for your industrial needs.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

Xinning Automatic Horizontal Flaskless Molding Line for Casting Iron Wit Green Sand

Xinning Automatic Horizontal Flaskless Molding Line for Casting Iron With Green Sand - leading factory for high-quality casting iron products. Contact us now!

Clay Green Sand Molding Production Line From Qingdao Manufacture

Get high-quality clay green sand molding production line from Qingdao Manufacture. We are a factory specializing in manufacturing top-notch industrial equipment.

Shipping Automatic Dl Sand Machine Core Foundry Metal Casting Machinery

Get high-quality Shipping Automatic Dl Sand Machine Core Foundry Metal Casting Machinery from our factory. We specialize in manufacturing top-of-the-line metal casting equipment.

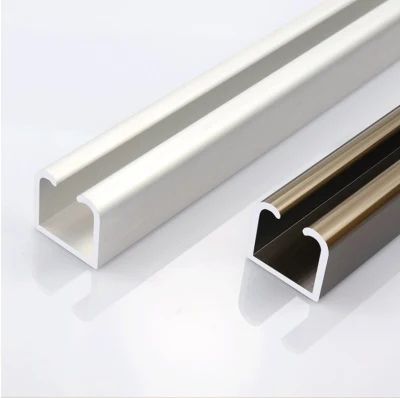

One Stop Solution Aluminium Alloy Solid Aluminum Track/Channel/Section Aluminum Mouldings

Looking for high-quality aluminum track, channel, and sections? Check out our One Stop Solution Aluminium Alloy Solid Aluminum Track/Channel/Section Aluminum Mouldings. We are a factory specializing in premium aluminum products.

KOCEL Customized Machinery Auto Motorcycle Cylinder Head Spare Part Sand Mold for Rapid Prototyping Casting & Low Pressure Casting & CNC Machining

KOCEL specializes in custom machinery and automotive spare parts, including cylinder head sand molds for rapid prototyping and low pressure casting, as well as CNC machining. We are a factory committed to high-quality production.

China Grey Iron/Stainless Steel/Brass/Copper/ Sand Casting/Investment Casting/Die Casting with Machining Parts

Introducing our factory: Top-notch {China Grey Iron/Stainless Steel/Brass/Copper/Sand Casting/Investment Casting/Die Casting with Machining Parts}. Providing high-quality products at competitive prices.

OEM Customized Auto Motorcycle Spare Parts Rapid Prototyping Engine Block Prototype by 3D Printing Sand Casting Stainless Steel CNC Machining

Rapid Prototyping Engine Block Prototype by 3D Printing Sand Casting Stainless Steel CNC Machining. We are a factory specializing in OEM Customized Auto Motorcycle Spare Parts.

Hino Jo5e/J05c 3D Printing Sand Casting Cylinder Head Engine Block Rapid Manufacturing CNC Machining

Rapid Manufacturing: Hino Jo5e/J05c Cylinder Head & Engine Block. 3D Printing, Sand Casting, CNC Machining. Factory-direct quality parts.

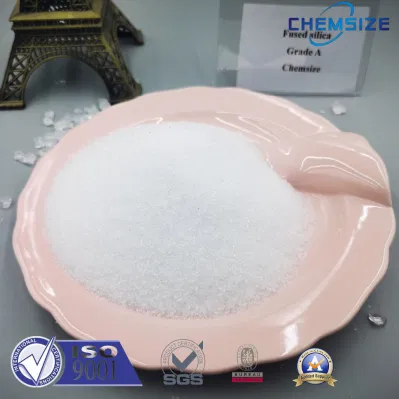

Fused Silica Powder and Fused Silica Sand for Making Refractory Lining Material

Fused Silica Refractory Lining Material - We are a factory specializing in producing high-quality fused silica powder and sand for refractory applications.

T1/T2/Tp1/Tp2 C10100/C10200/C10500/C10700/C11000 Square/Round Copper Bar

Shop our high-quality T1/T2/Tp1/Tp2 C10100/C10200/C10500/C10700/C11000 Square/Round Copper Bar. We are a factory committed to providing top-notch products.

Higher Class Aluminum Foil Container Making Mould

Get the best quality Higher Class Aluminum Foil Container Making Mould at our factory. We offer efficient and durable moulds for container production.

OEM Copper Zinc Casting Precision Auto Parts Sand Die Casting Lost Wax Investment Casting

OEM Copper Zinc Casting Precision Auto Parts Sand Die Casting Lost Wax Investment Casting - We are a factory specializing in high-quality metal casting products.

Hot Sale Kids Safe Non-Toxic Space Toy Sand/Educational Non-Toxic Customized Easily Modeling Shape Toys Play Sand

Discover our Hot Sale Kids Safe Non-Toxic Space Toy Sand! Our factory offers educational, easily customizable, non-toxic play sand for shaping and molding. Perfect for creative kids!

KOCEL Customized Sand Mold for Auto Spare Parts by Rapid Prototyping with 3D Printing Sand Casting & CNC Machining for Stainless Steel Metal Parts

Introducing KOCEL's Rapid Prototyping with 3D Printing Sand Casting & CNC Machining for Stainless Steel Metal Parts. We are a premier factory for custom auto spare parts.

OEM Lost Foam Clay Coated Resin Sand Gravity Ceramic Mold Precision Investment Dewaxing Vacuum Low Pressure Die Carbon Alloy Brass Casting

Precision OEM Casting Factory specializing in Lost Foam, Clay Coated Resin, Gravity, Investment, and Low Pressure Die Casting methods for various alloys.

Precision Steel Lost Wax Investment Vacuum Casting Factory

Precision Steel Lost Wax Investment Vacuum Casting Factory is a reliable manufacturer of high-quality metal parts. We specialize in precision casting techniques.

Professional Production Customization Ductile Iron Pipe Fittings Sand Casting Mold Making Equipment Cast Iron Product

CustomCast: Your go-to factory for professional sand casting mold making equipment and ductile iron pipe fittings production customization.

Foundry Green Sand Automatic Molding Machine Horizontal Flaskless Moulding Line for Aluminum Casting and Iron Casting

Explore our Foundry Green Sand Automatic Molding Machine Horizontal Flaskless Moulding Line for Aluminum and Iron Casting. We are a factory specializing in advanced casting solutions.

China Wholesale Elbow Foundry Metal Brass Alloy Carbon Stainless Steel Sand Aluminum Pipe Nipple Investment Iron Fitting Casting

Factory direct wholesale elbow foundry metal brass alloy carbon stainless steel sand aluminum pipe nipple investment iron fitting casting. Quality products at competitive prices.

Large-Capacity Exhaust Valve for High-Volume Fluid Systems

Upgrade your high-volume fluid system with our Large-Capacity Exhaust Valve. Designed for efficiency and durability. Buy direct from the factory.

- Lost Wax Investment Casting Manufacturer for Wholesale Export

- Reviews

- Related Videos

Welcome to our innovative Lost Wax Investment Casting process, where precision and quality come together to create exceptional products.

Our Lost Wax Investment Casting technique allows us to produce intricate and detailed metal parts with incredible accuracy and consistency. This advanced manufacturing process begins with a high-quality wax mold that is surrounded by a ceramic shell. Once the shell is formed, it is heated to remove the wax, leaving a perfect cavity that is ready to be filled with molten metal. The result is a flawless reproduction of the original wax mold, capturing every detail and dimension with exceptional precision.

Our Lost Wax Investment Casting method offers numerous benefits, including the ability to produce complex and intricate designs that are difficult or impossible to achieve with other manufacturing processes. It also allows for a wide range of materials to be used, from stainless steel and aluminum to bronze and titanium, ensuring that we can meet the unique needs of our customers.

Whether you are looking for precision-engineered parts for aerospace, automotive, or any other industry, our Lost Wax Investment Casting process is the ideal solution. With our commitment to quality and excellence, you can trust that our products will meet and exceed your expectations.

Experience the unmatched precision and quality of our Lost Wax Investment Casting process and discover the endless possibilities for your next project.

I recently purchased a beautifully crafted jewelry piece that utilized the lost wax investment casting method. The intricate details and fine finish of the product were absolutely stunning. The precision and accuracy of the casting process really came through in the final result. The quality of the material used was top-notch and the overall design was elegant and eye-catching. I was thoroughly impressed with the craftsmanship and attention to detail that went into creating this piece. I would highly recommend this method for anyone looking for high-quality, bespoke jewelry or other metal products.

Ms. Lily Huang

I recently purchased a Lost wax investment casting for a custom jewelry project, and I couldn't be happier with the results. The intricate details and fine finish on the wax mold were beautifully captured in the final metal casting. The process was seamless, and I was impressed with the precision and quality of the product. The investment casting technique truly captured the essence of my design, and I would highly recommend it for anyone looking for a high-quality, detailed casting for their projects. Overall, I am extremely satisfied with the Lost wax investment casting and will definitely be using it for future projects.

Ms. Cherry Wang

Contact us

Ms. Grace Wang: Please feel free to give your inquiry in the form below We will reply you in 24 hours