- Home

- Lost foam wax casting

Limited Offer: High-Quality Lost Foam Wax Casting Manufacturer in China

Introducing the innovative lost foam wax casting technology offered by Jiangsu Hongli Machine Co., Ltd. This cutting-edge casting method utilizes a unique pattern made of expandable polystyrene foam, which is coated with a refractory material to form a casting mold. As the molten metal is poured into the mold, the foam pattern vaporizes and the metal takes its place, resulting in a precise and high-quality metal part. This process allows for complex designs and intricate details to be achieved with ease, making it an ideal choice for a wide range of industries including automotive, aerospace, and machinery.

At Jiangsu Hongli Machine Co., Ltd., we are committed to providing top-notch lost foam wax casting solutions that meet the highest standards of quality and performance. With our advanced technology and expertise in the field, we can ensure the production of superior castings with minimal material waste and reduced machining requirements. Trust us to deliver exceptional lost foam wax casting solutions for your specific project needs.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

Casting Factory Automatic Pouring Machine for Foundry Equipment

Find top-of-the-line casting factory automatic pouring machines for foundry equipment at our factory. We are your reliable source for quality industrial equipment.

Sand Core Molding Casting Machine Foundry Sand Automatic Molding Machine

Get high-quality Sand Core Molding Casting Machine Foundry Sand Automatic Molding Machine from our factory. Efficient, precise, and reliable for all your casting needs. Contact us today!

Factory Price Customized Aluminum Alloy Gravity Casting Sand Casting Die Casting CNC Machining Sand Blasting X-ray Testing Machine Aluminum

Customized Aluminum Alloy Casting & CNC Machining Services at Factory Price. Specializing in Sand Casting, Die Casting, and X-ray Testing. Contact us now!

China Foundry Metal Zamak ADC12 Zinc Alloy/Aluminium/Aluminum/Aluminum Alloy/Aluminium Alloy Sand-Gravity-Die Casting for Machining Motorcycle Auto Body Part

Looking for high-quality metal casting products for motorcycle and auto body parts? Our China foundry offers top-notch sand-gravity-die casting for machining. Contact us now!

Competent Manufacturer High Precision Welding Part Zinc ODM Motorcycle Accessory

Manufacturer of high-precision welding parts for motorcycle accessories. Customizable zinc ODM options available. Contact our factory for more information.

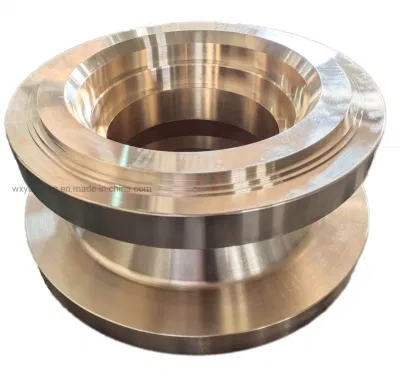

Casting Bronze/Copper/Brass Pump Body/Parts for Marine Boat Made by Sand Casting

Product name: Marine Boat Pump Body/Parts made by Sand Casting We are a factory specializing in casting bronze, copper, and brass pump body and parts for marine boats. Get high-quality, durable products.

Casting Bronze Valve Parts/Valve Trunnion/Bronze Valve Body/Valve Body

If you are looking for high-quality {Casting Bronze Valve Parts/Valve Trunnion/Bronze Valve Body/Valve Body}, our factory produces precision components for industrial valves.

100ml-20L Automatic Pet Bottle Blowing / Plastic Mineral Water Blow Molding Machine/Blow Moulding Machinery Price

Get the best deals on 100ml-20L Automatic Pet Bottle Blowing Machines at our factory. High-quality blow molding machinery at competitive prices. Contact us today!

Abrasive Material Walnut Grit / Walnut Shell Powder / Walnut Sand 40#

Introducing our Walnut Grit 40# - perfect for industrial applications. As a factory, we produce top-quality walnut shell powder for all your abrasive needs. Shop now!

Qt4-15s Automatic Hydraulic Construction Moulding Machinery/Affordable Automatic Concrete Cement Sand Hollow Paving Stone Brick and Block Making Machine

Looking for affordable automatic concrete brick making machinery? Our Qt4-15s automatic hydraulic construction moulding machinery is perfect for paving stone and block production. We are a factory specializing in high-quality construction equipment.

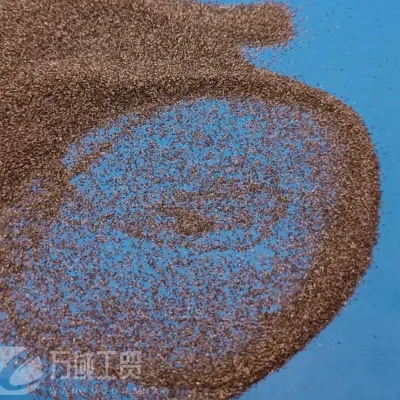

Brown Wear Resistant Alumina Sand 40# for Refractory Casting

Get high-quality Brown Wear Resistant Alumina Sand 40# for Refractory Casting from our factory. Durable and reliable for all your casting needs.

Abrasive Powder Rock Garnet Sand for Metal Parts Sandblasting

Get premium quality abrasive powder rock garnet sand for metal parts sandblasting at our factory. We offer reliable and efficient sandblasting solutions.

China Custom Hot Chamber Metal Parts and Sand Castings Housing Lost Wax Zinc Aluminium Die Casting Parts

Discover high-quality China Custom Metal Parts and Castings at our factory. From hot chamber die casting to lost wax casting, we offer precision parts in zinc and aluminum. Contact us today!

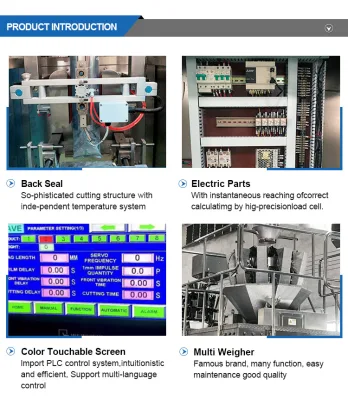

Lentils Legume Green Peas Chickpea Sand Clay Sunflower Granule Plastic Gusset Bag Granule Vertical Beans Packing Machine

Sunflower Green Peas Lentils Packing Machine - Factory direct packaging solution for legumes, chickpeas, and more. Quality granule packing equipment.

Vertical Machining Center Vmc855 CNC Milling Center

Looking for a reliable Vertical Machining Center Vmc855 CNC Milling Center? Visit our factory for high-quality precision machining solutions. Contact us now!

Powder Coating Black Aluminum Die Casting LED Flood Lighting

Shop our top-quality Powder Coating Black Aluminum Die Casting LED Flood Lighting. As a factory, we offer reliable products for all your lighting needs.

OEM Customized for Machinery Auto Motorcycle Spare Part Engine Block Cylinder Head Cover Housing of Rapid Prototyping by 3D Printing Sand Casting CNC Machining

Product Name: Customized Machinery Spare Part Rapid Prototyping Services Description: We are a factory specializing in rapid prototyping for OEM customized machinery spare parts using 3D printing, sand casting, and CNC machining.

China Green Sand Molding Machine, Foundry Casting Machine

China Green Sand Molding Machine, Foundry Casting Machine available at our factory. Delivering high-quality products for all your casting needs.

Stretch Gallon Water Bottle Moulding Making 2 Cavity Semi Fully Automatic Pet Plastic Maker Blower Blowing Molding Moulding Machine Price

Looking for a Stretch Gallon Water Bottle Moulding Making 2 Cavity Semi Fully Automatic Pet Plastic Maker Blower Blowing Molding Moulding Machine at the best price? Look no further! Our factory offers top-quality products.

Densen Customized Super Large Cast Steel Check Valve Body: Sand Casting Process

Densen specialized in manufacturing super large cast steel check valve body through sand casting process. Top quality and customization available.

- Lost Foam Wax Casting Manufacturer: Quality Casting Supplies from China

- Reviews

- Related Videos

Introducing our revolutionary lost foam wax casting process, a cutting-edge technique that allows us to create intricate and complex metal parts with unparalleled precision and efficiency. By using a foam pattern that is coated in a refractory material, we are able to achieve highly detailed and intricate designs that would be nearly impossible to achieve with traditional casting methods.

This innovative process offers numerous benefits, including the ability to produce near-net shapes, reduced machining and tooling costs, and the elimination of any parting lines or draft angles. Additionally, our lost foam wax casting technology allows for greater design flexibility, as it can accommodate thin walls, complex geometries, and internal features that would be challenging to achieve with other casting methods.

At our state-of-the-art facility, our team of skilled technicians utilizes the latest in casting technology and equipment to ensure that every part meets the highest standards of quality and accuracy. Whether you require prototypes, small batches, or high-volume production runs, our lost foam wax casting process is capable of delivering consistent and reliable results for a wide range of industries and applications.

Experience the future of metal casting with our innovative lost foam wax casting process. Contact us today to learn more about how this groundbreaking technology can elevate your next project.

I recently tried Lost Foam Wax Casting for a DIY metal casting project and I was really impressed with the results. The wax pattern was easy to create and the foam casting process was simple and effective. The detail and precision of the final metal casting were outstanding, and the surface finish was smooth and flawless. The Lost Foam Wax Casting technique allowed me to create intricate and complex shapes with ease. I highly recommend this method for anyone looking to create high-quality metal castings for their projects. It's a game-changer for DIY metal casting enthusiasts.

Mr. OLIVER CHEN

I recently tried the Lost foam wax casting method for a new jewelry project and I am thoroughly impressed with the results. The intricate details of the wax pattern were perfectly captured in the final metal casting. The process was surprisingly easy and the foam pattern simply vanished during the casting process, leaving behind a flawless product. The benefits of this method are countless, including cost-effectiveness, reduced waste, and the ability to create complex designs with ease. I highly recommend Lost foam wax casting for anyone looking to create high-quality metal products with intricate details.

Mr. Edwin Cheng

Contact us

Ms. Belan ForUDesigns: Please feel free to give your inquiry in the form below We will reply you in 24 hours