- Home

- Fused silica sand foundry

Fused Silica Sand Foundry Manufacturer | High Quality Supply from China

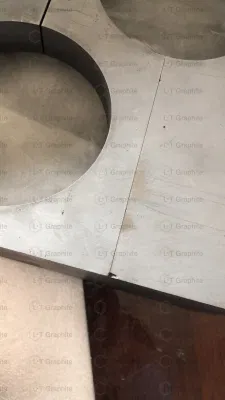

Introducing the newest innovation in the foundry industry, Jiangsu Hongli Machine Co., Ltd. is proud to present our premium fused silica sand. Specially designed for foundry applications, our fused silica sand boasts high purity and a consistent grain size, making it the perfect choice for precision casting. Our product offers excellent performance at high temperatures, ensuring the smooth and efficient production of high-quality metal castings.

At Jiangsu Hongli Machine Co., Ltd., we understand the importance of using top-quality materials, which is why our fused silica sand is carefully processed to meet the stringent requirements of foundry operations. With its exceptional thermal stability and low thermal expansion, our fused silica sand reduces cracking and veining in castings, resulting in superior finished products. Whether you're casting intricate components or robust industrial parts, our fused silica sand is the ideal solution for achieving accurate and flawless results. Trust Jiangsu Hongli Machine Co., Ltd. for all your foundry material needs.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

Foundry Green Sand Treatment Line Sand Casting Moulding and Reclamation Equipment System

Upgrade your foundry green sand treatment with our sand casting molding equipment. We are a leading factory with reclamation systems for improved efficiency.

Foundry Automatic Moulding Machines Green Sand Cast Iron Molding Line

Get high quality foundry automatic moulding machines for green sand cast iron molding line at our factory. Enhance productivity and efficiency today!

Customized Green Sand Casting Process Grey Iron Casting Company Forging and Casting

Introducing our Customized Green Sand Casting Process Grey Iron Casting Company, specializing in Forging and Casting. Highest quality products delivered.

Foundry OEM Metal Parts Iron Sand Casting for Gray Iron Ductile Iron Steering Gear

Get high-quality OEM metal parts with iron sand casting for steering gear. We are a factory specializing in gray and ductile iron casting. Order now!

Carbon Graphite Mold for Pressure Foundry Nonferrous Metals

Shop top-quality Carbon Graphite Mold for nonferrous metals pressure foundry at our factory. We offer durable and precise molds for your manufacturing needs.

OEM Auto Car Spare Accessory Machining Rapid Prototyping Aftermarket Low Pressure Casting Metal Part 3D Printing Sand Mold Foundry Supplier From China

Green Sand Automatic Moulding Production Line, Foundry Machinery

Green Sand Automatic Moulding Production Line. Top-notch Foundry Machinery. We are a factory specializing in high-quality metal casting equipment.

High Quality Precision Professional Parts Plastic Injection Molding Made Mould Tooling Manufacturer Maker Mouldings

Get high-quality precision professional parts with our plastic injection molding made mould tooling. As a factory, we are the leading maker of mouldings. Contact us today!

OEM Factory Sand Casting Gravity Casting Process Products Aluminum Die

Discover high-quality OEM factory sand casting, gravity casting, and aluminum die products. Our factory delivers top-notch precision and durability.

Static Pressure Horizontal Green Sand Moulding Line, Foundry Machine

Introducing our Static Pressure Horizontal Green Sand Moulding Line, the perfect foundry machine for your production needs. At our factory, we ensure high-quality manufacturing results.

Industrial Sand Casting Aps International Standard China Gold Melting Furnace

Discover top-quality Industrial Sand Casting Aps International Standard China Gold Melting Furnace at our factory. Get the best melting furnace for your needs. Contact us today!

Custom Aluminum Die Casting Zinc Alloy with Chroming Salt Spray Test 300h

Custom Aluminum Die Casting Zinc Alloy with Chroming Salt Spray Test 300h - We are a factory specializing in high-quality custom aluminum die casting and zinc alloy products.

OEM Customized Brass Casting CNC Copper Polishing Precision Machining for Decoration Parts

Get high-quality OEM Customized Brass Casting CNC Copper Polishing Precision Machining for Decoration Parts from our factory. Perfect for all your decoration needs.

KOCEL OEM Automotive Car Motorcycle Spare Metal Body Chassis Foundry Accessory Sand Mold with 3D Printing Sand Gravity/Low Pressure Casting Rapid Prototyping

KOCEL OEM Automotive Car Motorcycle Spare Metal Body Chassis Foundry Accessory Sand Mold with 3D Printing Sand Gravity/Low Pressure Casting Rapid Prototyping. We are a leading factory for high-quality automotive spare parts.

Custom Sand Casting Machining Parts OEM Copper Brass Sand Casting

Custom Sand Casting Machining Parts OEM Copper Brass Sand Casting - Our factory specializes in producing premium quality sand casting machining parts in copper and brass. Contact us for customizable OEM solutions.

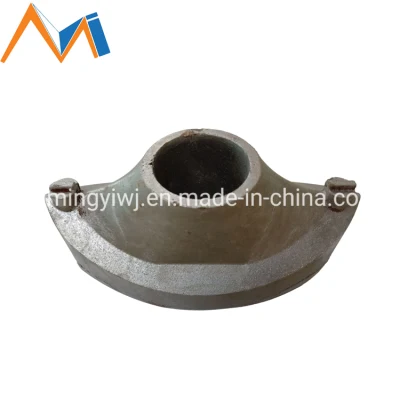

Cast Iron Post-Tension Anchorage Casting for Concrete Slab

Shop our high-quality cast iron post-tension anchorage casting for concrete slab. Factory direct prices. Durable and reliable. Order now!

Metal Piece Plastic Vacuum Models Truck Components Die Cast Mold Making Service Sand Casting Service

MetalTech Industries: Your go-to factory for top-quality Metal Piece Plastic Vacuum Models Truck Components Die Cast Mold Making Service Sand Casting Service.

Custom Die Casting Metal Stamping Rapid Prototype Manufacturer

Custom Die Casting Metal Stamping Rapid Prototype Manufacturer is a leading factory specializing in high-quality metal products. Get a quote today!

No Bake Furan Phenolic Resin Sand Mixing Equipment Continuous Sand Mixer

Get high-quality No Bake Furan Phenolic Resin Sand Mixing Equipment from our factory. Our continuous sand mixer is perfect for efficient and reliable sand mixing.

Professional Cast Iron Foundry Customized Part Green Sand Casting for Manhole

Get high-quality professional cast iron foundry customized parts for manholes with green sand casting at our factory. Contact us now for custom solutions.

- Fused Silica Sand for Foundry: Manufacturer, Supplier, and Exporter from China

- Reviews

- Related Videos

Introducing our premium quality fused silica sand, specifically designed for foundry applications. Our fused silica sand is meticulously produced using high-quality silica material, ensuring exceptional purity and uniform particle size distribution. This results in superior flowability, thermal stability, and mold hardness, allowing for precise and efficient casting operations.

Our fused silica sand is ideal for foundry processes due to its low thermal expansion, high chemical purity, and excellent thermal shock resistance. This ensures that the mold and core materials maintain their integrity and dimensional stability in high-temperature environments, resulting in high-quality castings with minimal defects.

In addition, our fused silica sand offers superior flowability and compaction properties, allowing for intricate and detailed castings with smooth surfaces and precise dimensions. This leads to improved productivity and reduced manufacturing costs, making it a cost-effective solution for foundry applications.

Furthermore, our fused silica sand is available in various grain sizes to accommodate different foundry requirements, and our team of experts is dedicated to providing tailored solutions to meet specific customer needs.

Overall, our fused silica sand is the perfect choice for foundries looking to enhance their casting processes and achieve exceptional results. With its outstanding quality and performance, our fused silica sand will undoubtedly elevate your foundry operations to new heights.

I recently purchased fused silica sand for my foundry project and I couldn't be happier with the quality. The sand is extremely pure and has a high melting point, making it perfect for casting metals. The fine grain size and consistency of the sand also make it easy to work with and create detailed molds. The high thermal shock resistance of the fused silica sand ensures that it can withstand the extreme temperatures of the foundry process without cracking or breaking. Overall, I highly recommend this product for any foundry project.

Ms. wanda chen

I recently purchased Fused Silica Sand for my foundry and I am thrilled with the results. The purity and high melting point of this silica sand make it perfect for casting intricate metal shapes with fine details. It flows easily and produces smooth, clean surfaces on my castings. The consistency of the sand allows for excellent mold reproduction and it holds up well under the intense heat of the foundry. I have found that it significantly reduces the occurrence of defects and ensures a high-quality finish on my metal castings. I highly recommend Fused Silica Sand for any foundry work.

Ms. Tina Ge

Contact us

Mr. Kendy Li: Please feel free to give your inquiry in the form below We will reply you in 24 hours