- Home

- Foundry line system

High-Quality Foundry Line System Manufacturer in China

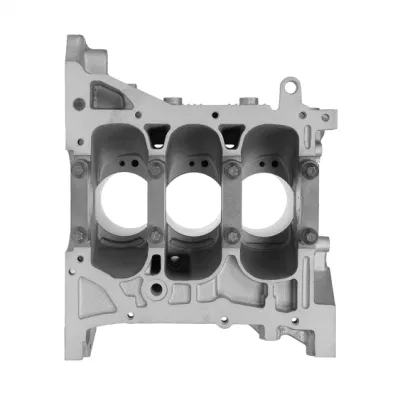

Introducing the cutting-edge Foundry Line System by Jiangsu Hongli Machine Co., Ltd. This innovative system is designed to revolutionize the production process in foundry facilities, ensuring maximum efficiency and productivity. The Foundry Line System is equipped with state-of-the-art technology, allowing for seamless integration and automation of various components within the production line. With its advanced control and monitoring capabilities, this system provides real-time data analysis to optimize performance and identify any potential issues. Not only does it streamline the production process, but it also enhances the overall safety and reliability of the operation. The Foundry Line System is meticulously engineered to meet the specific demands of foundry operations, delivering unparalleled performance and quality. With this cutting-edge system, foundry facilities can elevate their production capabilities and stay ahead of the competition. Experience the future of foundry production with the Foundry Line System by Jiangsu Hongli Machine Co., Ltd.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

Gravity Die Casting Machine Weight Die-Casting Equipment Foundry Factory Cast Machinery

Gravity Die Casting Machine - Leading weight die-casting equipment foundry factory. High-quality cast machinery for all your manufacturing needs.

Automatic Green Foundry Sand Molding Machine for Manhole Cover

Find the best Automatic Green Foundry Sand Molding Machine for Manhole Cover at our factory. We offer top-quality machines for efficient production.

Ultra-Fine Silica Sand Manufacturers for Foundry Needs

Discover top-quality ultra-fine silica sand for foundry needs at our manufacturing facility. Trust the experts in silica sand production.

Experienced Manufacturer CNC Precision Welding Component Steel Customized Metallurgical Machinery RoHS

High-Quality CNC Precision Welding Component, Steel Customized Metallurgical Machinery. Our experienced RoHS certified factory delivers top-notch products.

OEM Custom Sand Casting Ductile Iron Casting Foundry Factory at Qingdao

Welcome to our OEM Custom Sand Casting Ductile Iron Casting Foundry Factory at Qingdao. We are a leading factory specialized in producing high-quality ductile iron castings.

Quality Custom Brass/Iron/Aluminum Clay Sand Casting Centrifugal Pump Parts

Custom Centrifugal Pump Parts | Factory Direct -Durable brass, iron & aluminum sand casting parts for centrifugal pumps. Order now from our factory!

OEM Part Manufacturer Aluminum/Zinc/Brass/Alloy Metal/Steel Gravity/Sand/Die Casting

High-quality OEM Aluminum Die Castings from our factory. We specialize in producing precision metal castings for a wide range of industries.

Qtj4-26c Automatic Cement Sand Concrete Block Machine Brick Making Mould Africa

Looking for a reliable automatic cement sand concrete block machine? Our factory produces the Qtj4-26c brick making mould for Africa. Get the best quality and service here.

Metallic Casting White Metal Alloy Bearing Bushing Engine Bearing Alloy

Get high-quality Metallic Casting White Metal Alloy Bearing Bushing Engine Bearings Alloy from our factory. Durable and reliable products for your industry needs.

Customized/OEM Die Casting for Auto Parts

Boost Auto Performance with Customized Die Casting Parts. We are a leading OEM factory for automotive components. Order now for top-quality results.

Red Coated Precision Customized Aluminum Die Casting LED Light Housing

Get high-quality Red Coated Precision Customized Aluminum Die Casting LED Light Housings from our factory. Durable and reliable for all your lighting needs.

Custom Continuous Investment Vacuum Casting Machine Lost Foam Wax Lost Wax Sand Steel Casting

Introducing our Custom Continuous Investment Vacuum Casting Machine Lost Foam Wax Lost Wax Sand Steel Casting. We are a leading factory specializing in high-quality metal casting.

Superior Fused Silica Sand for Refractory Applications 50-100mesh Fe2o3 <0.003%

Get superior fused silica sand for refractory applications with Fe2O3 <0.003% from our factory. High-quality 50-100mesh sand for optimal performance.

Qingdao Daao China OEM/ODM Factory One-Stop Service Custom Sand Casting According to Drawings Ductile

Qingdao Daao China OEM/ODM Factory offers one-stop custom sand casting services for ductile products according to your drawings. Contact us today!

Die Casting Pressure Casting Investment Casting Sand Casting Engine Parts by Rapid Prototype Mass Production CNC Machining

Product Name: Rapid Engine Parts SEO Description: We are a factory specializing in rapid prototyping and mass production of engine parts through various casting and CNC machining processes.

Custom Made Sand Casting and Machining Gearbox Painted Parts

Custom Gearbox Painted Parts: High-quality sand casting and machining from our factory. Get durable and precision-engineered components for your machinery.

No Bake Sand (Furan Resin Sand / Alkali Phenol Resin Sand / PEP-SET Resin Sand) Molding Production Line

Discover high-quality No Bake Sand Molding Production Line products from our factory. Choose from Furan Resin Sand, Alkali Phenol Resin Sand, and PEP-SET Resin Sand options.

15 T/H Foundry Furan and Phenol Resin Sand Reclamation Line for Medium Casting

Discover our advanced 15 T/H Foundry Furan and Phenol Resin Sand Reclamation Line for Medium Casting. We are a trusted factory with top-quality equipment.

professional Customized Sand Die Casting Grey Iron Investment

Get high-quality customized sand die casting grey iron investment from our professional factory. Perfect for your industrial needs. Contact us now!

CE Certificate ISO Chinese Manufacturer PP Casting Streching Film Making Extrusion Automatic Production Machine

Get top-quality CE Certified ISO Chinese Manufacturer PP Casting Stretching Film Making Extrusion Automatic Production Machine from our factory. Contact us today!

- Premium Foundry Line System Manufacturer and OEM Supplier from China

- Reviews

- Related Videos

Introducing our state-of-the-art Foundry Line System, designed to revolutionize the production process for foundries around the world. Our innovative system is the result of years of research and development, and is designed to streamline the entire production line, from raw material input to finished product output.

Our Foundry Line System is equipped with advanced automation technology, allowing for seamless integration of various foundry processes. This includes material handling, core-making, molding, and casting, all managed by a centralized control system. With our system, foundries can expect improved efficiency, reduced labor costs, and increased productivity.

One of the key features of our Foundry Line System is its flexibility and scalability. Whether you are a small-scale foundry or a large industrial operation, our system can be customized to meet your specific production needs. With modular components and a user-friendly interface, our system can easily adapt to changes in production demands.

In addition, our Foundry Line System is built with a focus on safety and environmental sustainability. By optimizing energy usage and reducing waste, our system can help foundries meet the highest industry standards for responsible production.

Overall, our Foundry Line System represents the future of foundry production, offering a comprehensive solution for improving efficiency, reducing costs, and maximizing output. Partner with us and experience the power of our Foundry Line System in transforming your production line.

I recently installed the Foundry Line System in my metalworking facility and I have been thoroughly impressed with its performance. The system's automated processes have significantly increased our production efficiency, allowing us to meet tight deadlines with ease. The modular design of the system made it easy to integrate into our existing setup, and the user-friendly interface has made training new employees a breeze. The Foundry Line System has greatly improved our overall workflow and has proven to be a valuable asset to our business. I highly recommend this product to any metalworking facility looking to streamline their operations.

Mr. Wang Yongliang

I recently purchased a foundry line system and I must say, it has exceeded my expectations. The ease of use and efficiency of this system is truly impressive. The foundry line system has streamlined our production process and increased our output significantly. Its user-friendly interface and advanced technology make it a valuable addition to our operations. The durability and reliability of the system have proven to be top-notch, ensuring minimal downtime and maximum productivity. I highly recommend the foundry line system to any industrial facility looking to improve their manufacturing processes.

Ms. Tina Zheng

Contact us

Mr. Steven Lin: Please feel free to give your inquiry in the form below We will reply you in 24 hours