- Home

- Auto spare part rapid prototyping

Auto Spare Part Rapid Prototyping: Manufacturer in China

Introducing the latest innovation in auto spare part rapid prototyping from Jiangsu Hongli Machine Co., Ltd. Our cutting-edge technology allows for the rapid development and testing of auto spare parts, helping to reduce development time and costs. With our state-of-the-art prototyping capabilities, we are able to quickly produce high-quality prototype parts for testing and validation, allowing for faster iteration and refinement of designs. Our rapid prototyping process enables us to efficiently create custom parts with complex geometries, ensuring a high level of accuracy and functionality. Whether you are in need of a single prototype or a small batch of parts, our advanced prototyping capabilities can meet your specific needs. Trust Jiangsu Hongli Machine Co., Ltd. for all your auto spare part rapid prototyping needs, and experience the benefits of faster development cycles and increased product innovation.

Jiangsu Hongli Machine Co., Ltd.

Company News

Related News

Foundry Coated Sand Casting Shell Core Molding Machine

Get high-quality foundry coated sand casting shell core molding machines at our factory. Browse our selection for top-notch products.

Fd30s Automatic Servo Injection Blow Molding Machine for 2ml-2000ml Plastic Bottles

Get high-quality 2ml-2000ml plastic bottles with our Fd30s Automatic Servo Injection Blow Molding Machine. As a factory, we guarantee top-notch products.

Gusu Factory Equipment Chocolate Pouring Forming Machine Full Automatic Chocolate Moulding Line

Get the best quality Gusu Factory Equipment Chocolate Pouring Forming Machine Full Automatic Chocolate Moulding Line at our factory. We specialize in producing top-notch chocolate equipment.

New Delynn Wooden Package Automatic Casting Green Sand Molding Machine

Get top-quality New Delynn Wooden Package Automatic Casting Green Sand Molding Machine. We are a leading factory offering the best in manufacturing solutions.

KOCEL Customized Sand 3D Printer & Auto Spare Part Sand Mould for Rapid Prototyping with 3D Printing Sand Casting & CNC Machining Flywheel Housing

KOCEL offers customized sand 3D printer & auto spare part sand mould for rapid prototyping with 3D printing sand casting & CNC machining flywheel housing. Factory direct prices.

Aluminium Sand Cast-Gear Case

Get high-quality aluminium sand cast gear cases from our factory. Durable and reliable products for all your mechanical needs.

Resin Sand Molding Sand Casting Machine Tool Casting

Find high-quality Resin Sand Molding Sand Casting Machine Tool Casting at our factory. We produce durable and reliable products for your industrial needs.

Green Sand Automatic Moulding Production Line, Foundry Machinery

Green Sand Automatic Moulding Production Line. Top-notch Foundry Machinery. We are a factory specializing in high-quality metal casting equipment.

Custom Metal Sand Casting & Stainless Steel Precision Investment Casting and Machining Forging Parts

Product Name: Metal Casting and Machining Solutions Description: We are a leading factory offering custom metal sand casting, stainless steel precision investment casting, and machining forging parts. Quality assured.

Sand Casting Housing Manufacturer Large Steel Sand

Get high-quality sand cast steel housings from a reputable factory. As a leading manufacturer, we offer durable and reliable products for various applications.

Car Toy Plastic Mould Base Maker Plastic Injection Auto Toy Mold Base

Looking for a reliable car toy plastic mold base maker? Our factory specializes in plastic injection auto toy mold base manufacturing. Satisfaction guaranteed!

Low Price Horizontal Parting Flaskless High Pressure Foundry Molding and Casting Machine

Get the best deal on our Low Price Horizontal Parting Flaskless High Pressure Foundry Molding and Casting Machine. As a factory, we offer top-quality products at competitive prices.

Medical Equipment Parts Aluminum Gravity Casting Sand Casting Die Casting Sand Blasting Leak Tester X-ray Testing Aluminum Parts

Aluminum Medical Equipment Parts - Factory Direct Casting and Testing. Find High-Quality Aluminum Parts for Medical Equipment. Leak and X-ray Tested.

Injection Mould Factories Plastic Mould Making Mould Plastic

Plastic Mould Making: Top Injection Mould Factory. Specializing in custom moulds. Expert plastic mould makers. Get a quote today.

Cast Iron Horizontal Parting Flaskless Green Sand Moulding Machine Factory Price

Get the best deals on Cast Iron Horizontal Parting Flaskless Green Sand Moulding Machine Factory Price. As a factory, we offer top-quality products at competitive prices.

Mechanical Sand Moulding Machine for Foundry

Discover our high-quality Mechanical Sand Moulding Machine for Foundry at our reliable factory. Contact us for efficient and effective manufacturing solutions.

A356 A380 T6061 T7075 Auto Spare Part Engine Block Cylinder Head Rapid Prototyping 3D CNC Machining Printing Sand Casting

RapidPro 3D CNC Machining specializes in manufacturing auto spare parts like engine blocks and cylinder heads using advanced T6061 and T7075 materials. We also offer rapid prototyping and sand casting services. Visit our factory for high-quality products.

Furan Alkaline Phenolic Resin Sand Mixer Mixing Machine Supplier

We are a leading factory specializing in the production of Furan Alkaline Phenolic Resin Sand Mixer Mixing Machine. Contact us for top-quality industrial equipment.

Hot Sale Customized Ductile Resin Machining Cast Iron Sand Parts Sand Casting

Get durable and customized ductile resin sand cast iron parts at our factory's hot sale. We provide precise machining for top-quality results.

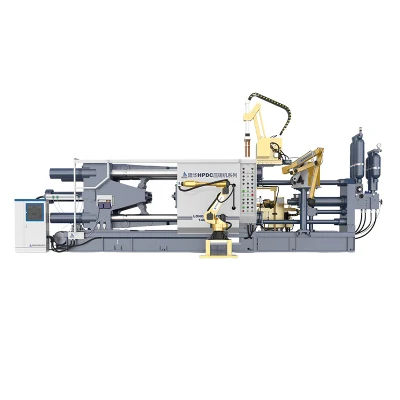

Lh-Hpdc 180t Computer Controlled Full Automatic Cold Chamber Aluminum Die Casting Machine

Our factory uses the Lh-Hpdc 180t Computer Controlled Full Automatic Cold Chamber Aluminum Die Casting Machine to create high-quality aluminum products.

- Rapid Prototyping for Auto Spare Parts: Leading Manufacturer in China

- Reviews

- Related Videos

Introducing our latest innovation in the world of auto spare part rapid prototyping - the SP-RP2000. Our state-of-the-art rapid prototyping machine is designed to revolutionize the way auto spare parts are developed and produced. With its cutting-edge technology and advanced capabilities, the SP-RP2000 is set to transform the automotive industry.

Our rapid prototyping machine is powered by the latest software and hardware, allowing for the quick and precise creation of auto spare parts. Whether it's a simple bracket or a complex engine component, the SP-RP2000 can produce high-quality prototypes in a fraction of the time compared to traditional methods. This means faster turnaround times for product development and ultimately, quicker time-to-market for auto spare parts.

The SP-RP2000 is also incredibly versatile, capable of working with a wide range of materials including plastics, metals, and composites. This means that regardless of the material requirements for the auto spare part, our rapid prototyping machine has you covered.

In addition, the SP-RP2000 is designed for user-friendly operation, allowing for seamless integration into existing workflows. This makes it an ideal solution for auto manufacturers, automotive suppliers, and repair shops looking to streamline their spare part development process.

Experience the future of auto spare part rapid prototyping with the SP-RP2000. Contact us today to learn more about how our innovative machine can revolutionize your production process.

I recently used the auto spare part rapid prototyping service and I was extremely impressed with the results. The process was quick and efficient, and the final product was of high quality. The precision and accuracy of the prototype was excellent, and it fit perfectly with the existing auto parts. The service provider was professional and easy to work with, and the turnaround time was very fast. I highly recommend this service to anyone in need of rapid prototyping for auto spare parts. It's a great way to test and produce new auto parts without the long lead times and high cost of traditional manufacturing methods.

Mr. Shuwen Zheng

I recently used an auto spare part rapid prototyping service and was extremely impressed with the results. The company was able to quickly produce high-quality prototypes of the desired spare parts, allowing me to test and evaluate their performance before mass production. The parts were made with precision and accuracy, and the entire process was smooth and efficient. The rapid prototyping saved me a lot of time and money, and I was able to get the spare parts I needed in record time. I highly recommend this service to anyone in need of fast and reliable auto spare part prototyping.

Ms. Elaine Cai

Contact us

Ms. Tina Ge: Please feel free to give your inquiry in the form below We will reply you in 24 hours